Tool Setting And Geometric Checking On Lathes And Turning Centers

People working with lathes and turning centers know about the problem of scrap parts being generated by broken or worn tools or tools which are not measured properly. It is quite common that end-users or operators are not provided with the correct instruments that detect the real tool dimensions during working cycles, fundamental information for the proper execution of production.

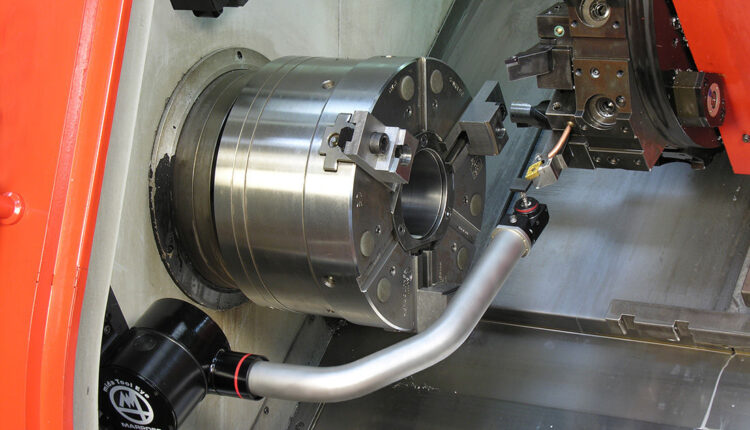

Auto Tool Setting before, during, and after the machining process enables the possibility to automatically acquire the exact values of length and diameter of different cutting tools. Tool Setters measure tools inside the machine working areas, thus in the real machining conditions. In this way, tool check becomes more meaningful and faster than pre-setting outside the machine.

Description

Tool setters enable two fundamental measurement phases: presetting and tool verification.

Thanks to the presetting phase, tools are measured on the machine before starting the machining process, such that the axis movements provide real dimensions and not theoretical ones used in the tool dimension calculations. Furthermore, it is possible to detect and compensate thermal drift of the machine by using the software cycles.

Tool verification allows detecting cutters and drills wear or breakage between different processes, in order to keep cutting quality under control.

Benefits

- Increase of production quality

- Constant level of production quality

- Time-saving in comparison with external or manual tool check

- Increase of machine productivity

- More accurate measurements, as they are performed in the real working conditions

- Possibility to check the tools between one working phase and another

- Automatic acquisition of measured values and tool table update

- Facilitation of operator’s activities

- Elimination of mistakes due to manual input of measurement values on CNC

Versions

Marposs proposes a wide variety of tool setters and related software cycles, which cover the most different application requirements on lathes and turning centers:

- Mida Arms, high positional repeatability measurement arms used for tool setting and checking on lathes. Manual, automatic, or removable arms are available. The tool setter consist of a fixed base and a mobile arm and a touch probe is mounted on the mobile arm

- Non-contact Tool Setting, in case you want to measure tools smaller than 1 mm and / or more complex measurements are necessary (e.g. run out, integrity check of cutter profiles)

- Vision Tool Setting, ideal for micro-tools and applications requiring extraordinary metrological performances (measurement accuracy less than 2 microns). Dedicated software cycles are available for cutting tools used in turning applications on different CNC control type

Marposs also develops measurement software cycles for every tool setter type and machine configuration.

This content was originally published on the Marposs website.