Smart Manufacturing With Four Linked Hexagon Solutions

Petford Tools Attracted by G-Code Simulation to Prevent Expensive 5-Axis Crashes

With the ongoing demands to the business to reduce lead times and costs from initial design concept to final production components coming off tooling, a large toolmaking company needed to look at fresh opportunities to streamline their process.

As they looked around the market place, Petford Tools were attracted to Hexagon’s renowned Smart Manufacturing solutions, as a few years earlier they had received demonstrations from VISI. In particular, they were impressed at being able to verify collision-free toolpaths with NCSIMUL, creating an identical digital twin of the machine tool to simulate the actual G-code.

Even though Petford Tools’ previous system was fully integrated into their factory processes and it was a major upheaval to replace it, Managing Director Adrian Lloyd says having a fully connected workflow now, with four of Hexagon’s seamlessly connected solutions, was “well worth it.”

Those four software packages: WORKXPLORE, used by the sales team; VISI for the mould designers; WORKNC for programming their 11 5-axis and 3+2-axis machine tools; and NCSIMUL to accurately simulate the toolpaths.

Petford Tools Ltd is one half of the Petford Group, designing and producing moulds for Petford Moulding, who use them on their own injection moulding machines to produce millions of piece parts every year for a range of industries. Products include interior and exterior automotive trim; interior aerospace trim, along with aero-engine parts; and a wide variety of products for construction, industrial, rail and marine industry sectors, along with commercial trucks, garden-ware, and F1 racing teams.

Design Director Ian Foy says it’s important that their mould tools are high precision due to the complexity of the tooling, with many moving components. Also, many of the moulded products need a high-quality surface finish. “So we have to ensure that the mould cavity finishes are of high quality, too. Some of the mould tool tolerances need to be +/- 0.01 mm.”

Many of the 114 employees across the group, use at least one of Hexagon’s solutions, and Tooling Operations Director Dave Parr says incorporating the Smart Manufacturing ethos across their processes contributes both to their vision: “Engineering Solutions for Tomorrow’s Challenges,” and their strategy: “One-stop-shop for our customer’s needs, offering multiple services to our customer base.”

Before a project reaches his tooling team, it has already seamlessly passed through WORKXPLORE and VISI. When the sales team receive an enquiry, often in the form of a CAD model, the file is imported into WORKXPLORE for an initial design and feasibility review, enabling them to provide accurate costing of the job for a custom quote.

Ian Foy explains that WORXPLORE really does live up to its reputation of being a high-speed CAD viewer and analyser. “It’s particularly effective at reading different CAD formats extremely quickly, so we can import large CAD files and assess them immediately. This is a major benefit for us, as our previous CAD package was quite lethargic with larger size files.”

Any additional index modifications are done in VISI. But VISI really comes into its own once the order has been placed. “We use it to work closely with the customer on creating a final, feasible cost-effective product for robust tooling. Then we proceed with full tool design in VISI.”

Once the mould tools have been signed off, the files are imported into WORKNC where the toolpaths are created for the company’s 3+2 and 5-axis machining strategies. This software solution provides automated, efficient toolpaths which deliver dramatic productivity gains through shorter machining times, longer tool life, the improved surface finish which Petford Tools need for many of their moulds, and better machine utilisation.

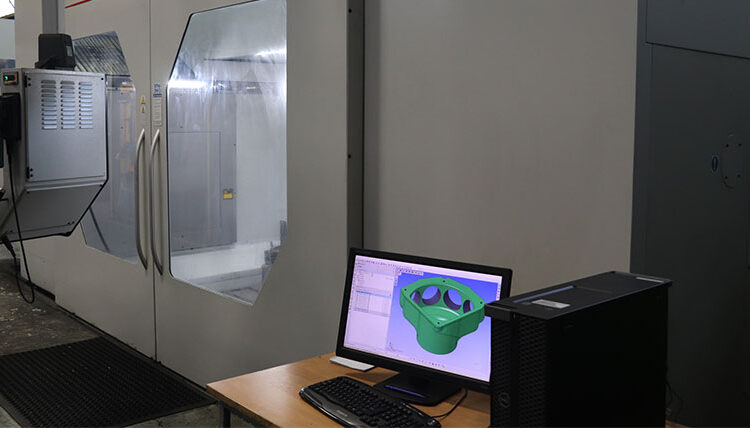

But before starting to cut metal, they need to know that the toolpaths are 100 per cent accurate. Dave Parr says: “With 5-axis machining, collisions would be very expensive, both in terms of money and wasted time, so we run a full simulation of the G-code in NCSIMUL.”

This is achieved by virtually building up a digital twin of the real-life machining environment, which also shows tool wear and tool load.

When the tools are ready, they move to Petford Moulding to start running off products on 11 Krauss-Maffei and Engle injection moulding machines ranging from 160-tons to 1,700-tons lock, equipped with pick and place robotics. Moulding services include trial support (APQP quality validation) with full dimensional analysis and 24/5 volume support.

Overall, seamlessly integrating Hexagon’s four solutions to create a single, connected workflow, enhances the dedicated one-stop-shop services that Petford provides for its customers, including tooling modifications, tooling texture, and 24/7 breakdown/repairs, along with full CAD technical support and project management. And for customers wanting a lower-cost product, a team of technical engineers are based in Shenzhen, providing Petford’s ‘Low-Cost Far East option.’

Concluding, Adrian Lloyd says the connected workflow that Hexagon brings to their operation, readily overcomes their biggest challenge, which is meeting customers’ demands for lower costs. “WORKNC and VISI handle the full data of large models much better than our previous system, meaning we can import and work on it quicker. This allows us to be more proficient throughout the workshop. We can react quicker with WORKXPLORE at the start of a project, and NCSIMUL ensures that there are no holdups during the machining process.”

This content was originally published on the Hexagon Manufacturing Intelligence website.