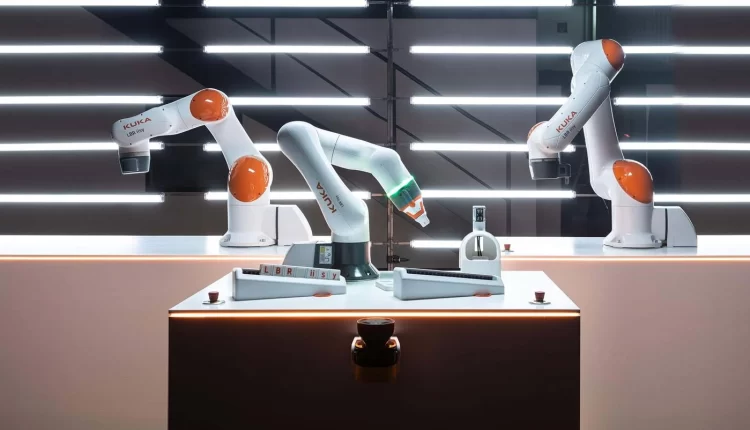

KUKA: More applications, the familiar simplicity; the new LBR iisy cobots

LBR iisy makes robotics and automation easy – from setup and teaching through to servicing

With the lightweight cobots of the LBR iisy series, robotics is made easy – because start-up is accomplished in just a few minutes, even with no prior knowledge of robotics or programming skills. This is made possible by the new KUKA iiQKA.OS operating system that is easy and intuitive to use.

Together with the LBR iisy version for 3 kg payloads, which is also available as a series product, the new “big iisys” are the first robots to run on iiQKA.OS. Typical areas of application for the collaborative robots of the LBR iisy series are in the flexible automation of pick & place, assembly, testing and handling tasks as well as the loading and unloading of machines. All cobot robots in the LBR iisy series are suitable for industrial applications, offer a very good price/performance ratio and feature full KUKA service.

LBR iisy stands for an “easy customer experience”

First-class hardware meets intuitive software: in combination with the new iiQKA.OS, the LBR iisy series promises a completely new robotics experience. The cobots are ready for use in less than 90 minutes – and programming using drag-and-drop functions, convenient teaching via the ergonomic Commander and operator control via the smartPAD pro make robotics easier and quicker than ever before.

The joint torque sensors of the cobots enable operation without a safety fence, facilitate teaching by means of manual guidance and, if desired, safe cooperation and collaboration between humans and robots. Small and medium-sized companies in particular benefit from the fast start-up of the LBR iisy with no major integration effort and no special know-how required.

Unlike conventional industrial robots, cobots are used to supplement human labor. The manual guidance teaching function makes automation faster and easier.

Higher payload capacities, greater reach, more freedom: LBR iisy 11 kg and LBR iisy 15 kg

The payload capacities of the two new LBR iisy variants are 11 and 15 kg respectively. The reaches are 1,300 and 930 mm respectively. Both robots can be mounted on the floor as well as on the ceiling or wall and meet the requirements of protection class IP54. They are thus protected against dust and moisture.

Furthermore, human safety is a top priority in automation with the LBR iisy cobots: from the injury-preventing design to implementation of the robot system’s safety functions. The collaborative robots are controlled using the space-saving KR C5 micro, which allows the robot system to be operated with 230 volts and thus makes the range of potential applications even more flexible. In the KUKA Marketplace, cobot manufacturer KUKA offers accessories that are perfectly coordinated with the overall system. These include, for example, grippers or vision sensors for various automation applications.

The LBR iisy cobots make it possible to open up new applications for automation. Perfectly suited to small and medium-sized companies.

We developed the LBR iisy so that smaller companies can also benefit from robotics. In conjunction with the new iiQKA.OS operating system, special knowledge is no longer required for this.

This content was first published on the KUKA website.