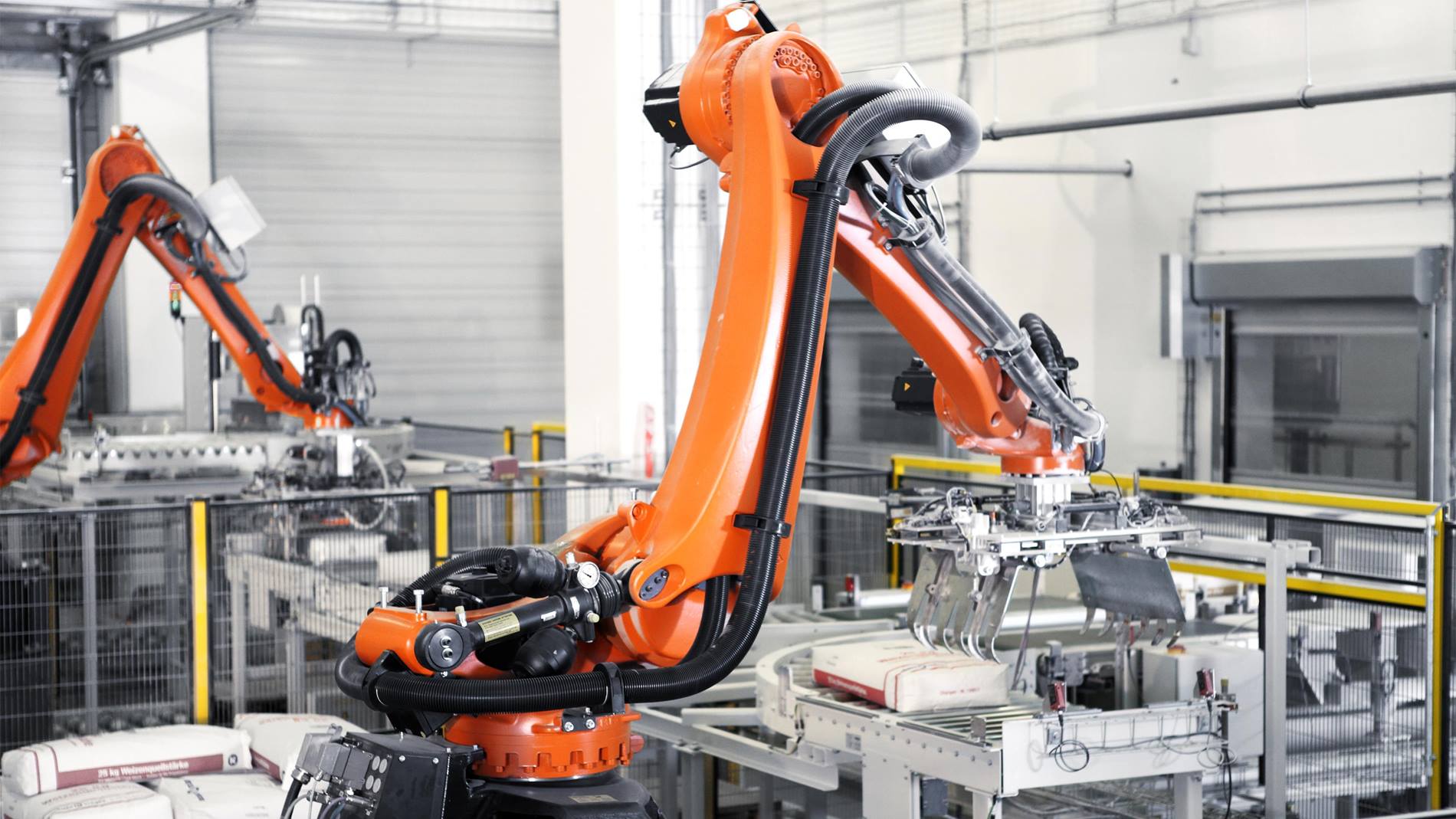

Kuka KR QUANTEC PA palletizes faster than ever before

The strongest palletizing robot on the market is even faster: The second generation of the KR QUANTEC PA impresses with reduced cycle times. Thanks to a payload of up to 240 kg, the robot packs a real punch, and the version with food-grade NSF H1 lubricants is also a real asset for the food industry.

Performance redefined

“With the second generation of the KR QUANTEC PA, we have achieved a perfect balance between axis speed and acceleration – for the best cycle times,” says Michael Laub, the responsible product manager at KUKA. For example, the robot type with a payload of 240 kg achieves 28.3 cycles per minute. “It was also important to us to increase the axis speeds, for example for long 180° rotary movements or layer formation when palletizing.” In order to meet the increased requirements of the consumer goods industry, especially the food industry in the secondary area, KUKA also offers the palletizing robot in the version “Hygienic Oil” (HO) on. All axes, as well as the energy supply, are equipped with food-grade NSF H1 lubricant.

New generation, better performance: The KR QUANTEC PA palletizing robot is the world leader in terms of speed

New generation, better performance: The KR QUANTEC PA palletizing robot is the world leader in terms of speedSustainably cost-effective

Innovative cell concepts for palletizing tasks

“A KR QUANTEC PA is a sustainable investment in the future of production,” says Michael Laub. “In interaction with the KUKA.PalletTech technology package, the robot enables innovative cell concepts for palletizing tasks, especially with a view to the consumer goods industry.” Here, maximum performance meets minimum programming effort – for extremely fast commissioning.

This content was first published on the Kuka website.