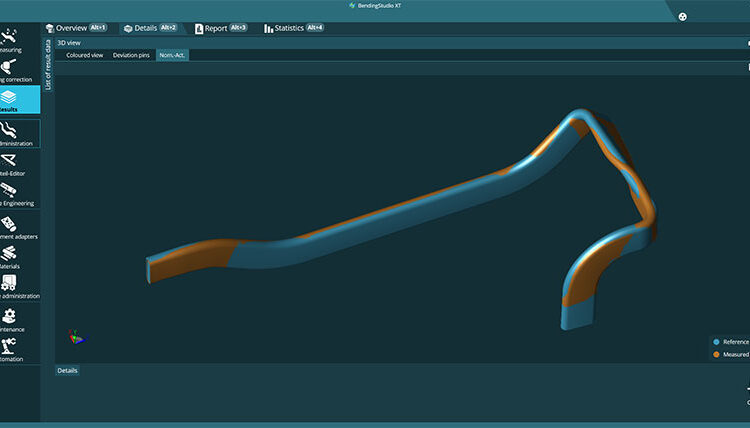

Hexagon’s Manufacturing Intelligence division today launched the new generation of its market-leading BendingStudio software platform. A specialized solution for tube measurement, analysis, and production machine control, the new BendingStudio XT builds on the key existing features of the platform. This latest version supports ultra-high-speed camera-based measurement, both manual and automated, as well as portable measuring arm functionality covering laser scanning, touch probing, and infrared probing. This full range of measurement hardware options makes BendingStudio XT a complete end-to-end solution for every application in the tube and wire production sector.

From tube and wire inspection to manufacturing and reverse engineering applications, BendingStudio XT is a full-featured measurement solution with the capacity to step beyond inspection to feedback directly into the production process. BendingStudio XT can connect directly to all prominent CNC bending machine models, allowing for the simple and immediate correction of production errors from directly within the software. When paired with high-resolution TubeInspect hardware, this process can even be completely automated with robot integration to deliver a 24/7 production-inspection feedback cycle right on the shop floor.

“With our existing BendingStudio and TubeShaper platforms, Hexagon brings unmatched expertise to the market when it comes to dedicated software for tube measurement”, says Stephan Amann, Metrology Devices VP Sales, and Marketing at Hexagon. “With this latest generation of BendingStudio, we wanted to bring all that tube bending experience and expertise together within a single platform, something that would allow our tube production partners to get all their tube measurement functionality ‘under one roof’.”

Hexagon currently offers a wide range of hardware solutions for tube inspection, all of which are now compatible with measurement through BendingStudio XT. The TubeInspect range is a high-speed solution based on an array of cameras positioned within a self-contained measurement cell; it offers instantaneous high-definition measurement for even freeform tubes, with the option to be integrated within a fully automated production line. The Absolute Arm offers more portable tube inspection, with the capability of measurement with the Absolute Scanner AS1 as well as with infrared tube probes or touch probes.

BendingStudio XT now supports Hexagon’s innovative rectangular tube measurement functionality, a key area for development in areas such as agricultural machinery production. Also added in BendingStudio XT is improved reporting functionality, with more flexibility for developing automated reporting custom-designed to fit the needs of individual use-cases.

With this new version, BendingStudio will retain all its previous capabilities, including the ground-breaking BendXtract algorithms that power the platform in providing free scanning, automatic extraction, and smart reporting functionalities.

“Tube and wire production is everywhere, spanning industrial boundaries in a way seen for few other manufacturing applications, and that means any tube measurement solution demands an extremely high degree of flexibility”, explains Günter Suilmann, Global Sales Director for Tube Solutions. “Whether that’s freeform tubes, elastic wires, highly complex bends, bend-in-bend geometries, varying tube lengths, large diameters, or otherwise unusual cross-sections, BendingStudio XT is a consolidated software platform capable of handling everything the tube industry can throw at it.”

BendingStudio XT is available immediately from Hexagon sales offices and distributors, both as a standalone software package for current TubeInspect and Absolute Arm owners and as a full product package including both the BendingStudio XT software and a TubeInspect cell or Absolute Arm with the scanner. Current owners of BendingStudio who wish to add more hardware to their existing toolkit will be able to simply upgrade their existing software package alongside the purchase of a TubeInspect or Absolute Arm.

This content was originally published on the Hexagon MI website.