Exact Metrology: A Division of In-Place Machining Company and a comprehensive 3D metrology service provider and hardware sales company, kicked off a new initiative to raise awareness of the capabilities of In-Place Machining Company.

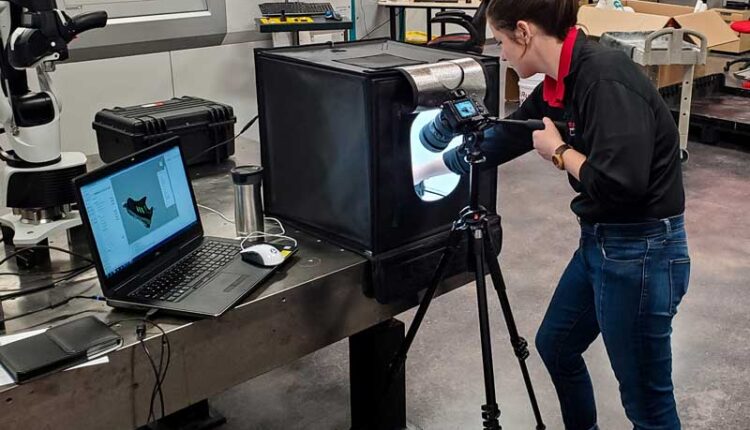

Taking place across the company’s social media platforms each Monday, hence the hashtag #MachiningMonday, this marketing tool will lead to a greater awareness of all the services that (IPM) offers. This concept was developed by Kelly Baldasare, Content Creator at the Exact Metrology Cincinnati, Ohio office. Besides raising awareness, Baldasare hopes that it will “…show the power of what IPM, Exact Metrology, and now the newly acquired OASIS Alignment Services can do together as one team.”

People often ask, “How does metrology work with machining?” The answer is that the possibilities are endless. #MachiningMonday wants to answer this question by showcasing the extensive on-site machining and engineering capabilities of IPM. Baldasare added, “Most people don’t recognize this, but a lot of machining services require metrology and/or precision alignment to make sure accuracy is obtained and to make sure there is no component damage that is being missed before services are performed.” For example, #MachiningMonday recently showcased IPM’s field machining services including lapping and grinding, tapping and reaming, axial, radial and thrust bearing field machining without shaft rotation.

While headed by Baldasare, this initiative is also being driven by Keith Naidl (Creative Services Director of In-Place Machining Company) and Katherine O’Maley (Marketing Manager of OASIS Alignment Services: A Division of In-Place Machining Company). Baldasare is excited to continue bringing new rhetoric to the Exact Metrology discussion. She concluded, “We are all very excited about how our joint capabilities will benefit our customers and we look forward to solving their most challenging issues together as one team.”

This content was first published on the Exact Metrology website.