ENGIE Lab CRIGEN and Ansys Accelerate Zero-Carbon Energy

ENGIE Lab CRIGEN is ENGIE’s corporate R&D center dedicated to green gases (hydrogen, biogas, liquefied gases, etc.); new energy uses in cities, buildings, and industries; and emerging technologies, including digital transformation, artificial intelligence, drones, robots, nanotechnologies, and sensors. These are the main missions of Engie Lab CRIGEN.

To guide its customers toward a greener and more ecological energy source, ENGIE Lab CRIGEN relies on Ansys’ digital twin technology to accelerate the zero-carbon energy transition for its customers.

Meet Nicolas Meynet, Multiphysics Simulation Expert at ENGIE Lab CRIGEN since 2016. Nicolas and his team are using Ansys Twin Builder to develop an engineering platform that delivers real-time 3D high-definition results from CFD (computational fluid dynamics) simulations.

Nicolas Meynet, Key Expert – Multiphysics Simulation, Future Industry Lab, ENGIE Lab CRIGEN

Reduce Simulation Time From Hours to Seconds With Ansys’ Reduced-Order Modeling (ROM)

One of the main missions of ENGIE Lab CRIGEN is to develop new smart and connected technologies to reach its “100% green gas” objective and thus reduce the carbon footprint.

ENGIE Lab CRIGEN develops simulation-based digital twins for industrial combustion plants to solve complex problems through advanced numerical simulations, which have long calculation times. Thanks to reduced-order modeling (ROM), which enables combining a CFD model with Ansys Twin Builder, these calculation times can be reduced considerably.

“The Ansys reduced-order modeling approach allows us to go from simulation times of several hours, or even days, to a few seconds,” says Nicolas. “The use of digital twins, and in particular ROM technology, completely changes the way digital simulation is used.”

The ROM allows ENGIE Lab CRIGEN engineers to explore the modeled equipment in a much more advanced and precise way. They can study the impact of different physical parameters in real-time and optimize the operation of the equipment by feeding the numerical simulation with data from the physical equipment. Once connected to the real asset, the ROM then becomes a digital twin, which can be used to perform predictive maintenance, capitalize on operating data or analyze a multitude of scenarios, all in a couple of seconds.

“This real-time technology allows us to observe and predict the behavior of our installation, and thus test strategies for the operation of the equipment by implementing, testing, and validating different scenarios instantly on the digital twin before deployment on the equipment,” adds Nicolas. “The customer can better understand, anticipate and validate the proper functioning of his installation by virtually testing the changes on the equipment.”

Making the Invisible Visible With Simulation

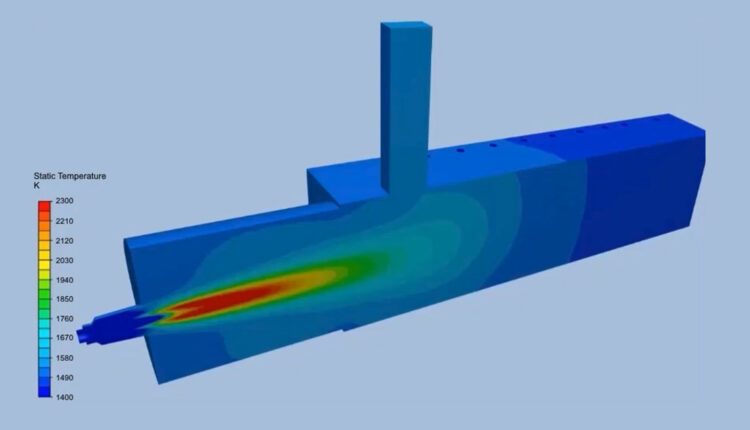

Before the use of digital twins, manufacturers and onsite technical experts tested their physical equipment without being able to visualize what was going on inside the equipment. For example, in an industrial furnace when the power or fuel was modified, the experts could not visualize or predict the impact on the flame length, the combustion quality, or the heat transfer efficiency to the load. All this is now possible thanks to ROM and simulation-based digital twin.

“Using Ansys’ digital twin technology allows us to optimize performance and make the invisible visible, in real-time,” says Nicolas.

With Ansys Twin Builder, ENGIE Lab CRIGEN has a digital twin of an industrial furnace.

Ansys Twin Builder: A Key Technology in ENGIE Lab CRIGEN’s Innovation

ENGIE Lab CRIGEN’s R&D experts have succeeded in developing the first technology stack of their industrial digital twin with an industrial furnace, thanks to Ansys Twin Builder.

Before using Twin Builder, ENGIE Lab CRIGEN had an experimental industrial furnace equipped with numerous physical sensors connected by wire. With Twin Builder, ENGIE Lab CRIGEN has a digital twin of the industrial furnace, complete with virtual sensors that collect detailed data from the heart of the equipment to ensure it is functioning properly and enabling them to anticipate possible failures via predictive maintenance.

The digital twin is currently connected to the industrial internet of things (IIoT) platform, which allows the physical separation of the industrial equipment from the digital twin. Ansys Twin Builder Runtime technology will enable better performance, and ease of use and maintenance.

“The deployment of the digital twin via an IIoT platform is a major step forward,” Nicolas says. “In particular, this should enable a remote maintenance of the physical industrial equipment.”

Digital Twins to Anticipate and Minimize Energy Consumption

The use of Ansys Digital Twin technology enables real-time optimization of energy and environmental performance of equipment: a key asset in the zero-carbon transition for Engie’s customers.

The other major benefit of using digital twin technology is to be able to anticipate the aging of physical equipment to improve its performance and thus considerably reduce maintenance costs.

“Digital twins facilitate the evolution of industrial equipment,” says Nicolas. “If we take the example of equipment that has been running on natural gas for years, thanks to digital twin technology, we can test and predict the behavior of the equipment with the addition of hydrogen, and thus facilitate this energy change on the existing industrial equipment thanks to simulation.”

Ansys’ digital twin technology also allows Engie to support its customers in the development phase of their industrial equipment, reducing the costs associated with physical prototypes.

“Thanks to the digital twin, our customers will be able to test different scenarios on their future equipment in the design phase and optimize their equipment, all this virtually and without a physical prototype,” says Nicolas. “Our customers will be able to test, optimize and validate the design of their equipment virtually before production. “

This content was originally published on the Ansys website.