Desktop Metal Announces Broad Availability of the Shop System™ Forust Edition, the World’s First High-Speed 3D Printer for Upcycled Wood Parts

The Forust wood printing process was first announced in May 2021 with an online storefront serving customers with custom parts and beta printer system deliveries. After serving customers and refining the process, Desktop Metal is now shipping easy-to-use, turnkey wood printing systems.

With the Shop System Forust Edition, architects, designers, and manufacturers can produce luxurious custom wood pieces that combine design and functionality for home decor and lighting, consumer products, architectural design, and automotive applications.

“Our new Shop System Forust Edition makes it easy to create custom and complex wood designs with a 3D printer on demand, circumventing supply chain challenges and delivering all-new design possibilities,” said Ric Fulop, Founder and CEO of Desktop Metal. “One of the great things about binder jet 3D printing technology is it can transform virtually any powder material into functional, end-use parts. Beginning with an ample supply of sawdust byproduct from the traditional wood milling industry, we are using our technology to build cradle-to-cradle manufacturing for wood. We believe this concept has the ability to deliver a meaningful sustainability impact and expand to other powdered waste materials over time.”

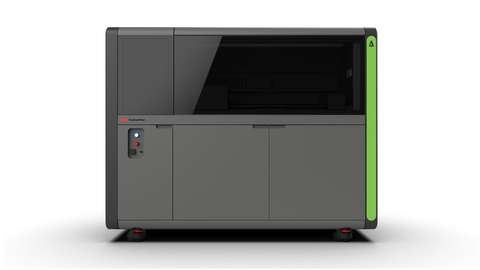

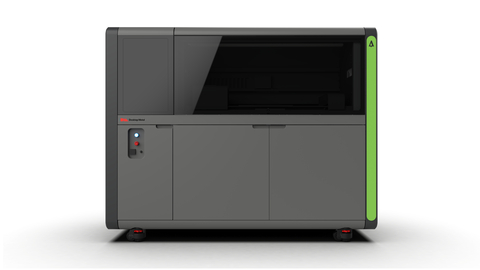

A Turnkey Wood Printing Solution

Through advanced printheads and high-speed binder jetting technology, the Shop System™ Forust Edition delivers high-resolution 3D printing of wood parts with realistic grain patterns. Additive manufacturing also offers a viable use for wood waste and intricate, complex designs previously unobtainable with traditional subtractive wood processing methods.

The complete system incorporates key safety features to enable 3D printing combustible wood powder and includes:

- Fabricate MFG build prep software, which allows users to print parts with no grain pattern or four grain patterns that can replicate ash, mahogany, and more.

- Shop System Forust Edition binder jet 3D printer with a build box of 350 x 222 x 200 mm (13.8 x 8.7 x 7.9 in) and a print speed of up to 1,600 cc/hr. That is about 21 mm or ⅘ of an inch in Z-height per hour.

- Forust Powder Station, which allows users to remove printed parts from the build box and recover loose sawdust powder for immediate reuse in the printer.

- Forust Wood Powder, a special blend of raw or unfinished sawdust from the traditional wood milling industry.

- Forust Binder, which comes in clear and brown colors to bind wood powder particles and create natural-looking wood grain patterns that flow across the entire part.

- A wood parts post-process guide that walks users through a recommended workflow for infiltrating parts after 3D printing with USDA certified bio-based resins.

After infiltration, Forust parts can be sanded, stained, polished, dyed, coated, and refinished in the same manner as traditionally manufactured wood products. Infiltrated Forust parts have strength similar to traditional wood and can be screwed or nailed.

Currently, the Shop System Forust Edition printer processes Desktop Metal-provided wood powders from verified and consistent supply sources. Guidelines are in development to allow customers to print their own recycled sawdust powders in the future.

Binder jetting is a 3D printing process that transforms powdered materials — metal, sand, ceramic or other powders — into highly dense and functional precision parts at high speeds. An industrial printhead selectively deposits a binder into a bed of powder particles creating a solid part one thin layer at a time, just like printing on sheets of paper. The technology is viewed as a desirable and sustainable production method, largely because of its high speed, low waste and cost, as well as material flexibility, as demonstrated by the Shop System Forust Edition.

This content was first published on the Desktop Metal website.