Ansys Helps Innoviz Technologies Build a Better Automotive Lidar

Every year, according to the World Health Organization, approximately 1.3 million people will die in car accidents worldwide. Thankfully, there are advanced driver safety systems (ADAS) designed to improve the safety of a vehicle in various driving situations. A more significant technological milestone, however, will be when fully autonomous vehicles take over the road.

With an understanding that human error accounts for many, if not most of these traffic accidents, removing the driver from this equation is a promising next step. Lidar is a critical component in the future of autonomous driving, yet most of the lidar that are commercially available fall short of ideal automotive requirements.

Innoviz Technologies, an Israel-based lidar manufacturer, is drawing on the simulation power of the Ansys ecosystem to advance a lidar that meets performance, reliability, size, and cost requirements in a more compact design.

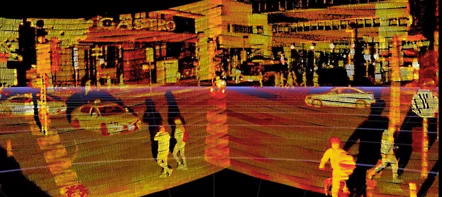

Of course, all this forward momentum depends on the sensing capability of the vehicles themselves, defined by a complex system of lidars, radars, and cameras. Among them, lidars are the only sensor technology that can provide high-resolution, long-range 3D image perception. The sensor technology is specifically used for determining the variable distance of an object using a pulsed laser that sends light beams out in all directions. An object’s distance from the vehicle is then calculated based on the time it takes for the laser pulses to bounce back to the laser scanner. Recording each laser beam’s reflection point, an onboard computer generates a “point cloud” or 3D representation of the objects around it.

Lidar technology plays a central role in autonomous driving technology, yet most lidar products today are too expensive, too big, or too unreliable for mass market. To compound matters, they are very complex products involving many technologies in their production and operation. Using a naive build-test-iterate approach, it is possible to establish a development process that will not successfully converge or result in a long development arc involving many expensive product iterations. Producing a new part design can take from weeks to months, so every part needs to be designed to the best possible degree of accuracy before it is released to production. To contain system development costs, the goal is to minimize the number of design iterations. For this reason, Innoviz turned to Ansys simulation software to manage product validation to hit their design target of validating each sample the first time around.

“One of the biggest ways in which Ansys simulation tools help us is in reducing production cycles,” says Oren Buskila, Chief R&D Officer and Co-Founder of Innoviz. “The software, on average, saves us around two design cycles per product. Each full design cycle is around 8 months, so roughly speaking, we’ve saved approximately a year and a half over the course of an entire project. Over a 5-year-long project, this time savings is huge.”

Optimizing Automotive-Grade Lidar Design with Simulation

To design a high-performing, reliable automotive-grade lidar that is small enough to satisfy consumer price perceptions, Innoviz used Ansys software to support an entirely new, unique design concept in lidar technology. Through an extreme integration of the electronic system components, Innoviz made a lidar that is significantly smaller and much less costly for manufacturers to use by integrating many different system electronics into a single system-on-chip (SoC), and replaced the scanning method of the lidar, which is generally mechanical in nature. Most lidars are spinning systems driven by a big motor with many lasers and detectors affixed to them. Innoviz Technologies replaced this system with a single scanning element and fewer lasers, further scaling back to a much smaller, less expensive lidar that is also much more reliable.

To support their innovative lidar system, Innoviz relies on many Ansys simulation solutions for testing and validation across the whole design chain of their products. For example, they use Ansys Mechanical for both mechanical and optical system parts that make up their lidars, for structural analysis to determine mechanical robustness and stability of a part, and dynamic simulation to assess behavior under vibration. Innoviz Technologies’ product development team also uses Mechanical for thermal simulation to see how much power can be dissipated from the main components inside, such as the SoC or the laser. Additionally, Ansys Fluent is used as part of thermal analysis to simulate airflow inside and over the unit, and simulation tools such as Ansys Maxwell for parts that have electromagnetic elements to their operation. And with Ansys Zemax software, Innoviz can run both sequential optical simulation and non-sequential optical simulation to simulate both the desired path of light integral to object detection, as well as the non-desired stray light, that needs to be minimized by design.

“We really appreciate the Ansys tools interface,” says Buskila. “We can use a single design reference and then run it through the different simulation tools without needing to convert or to redesign the part for simulation in different tools. I like that fact every Ansys simulation solution is part of a greater ecosystem rather than just a separate tool. Ansys also keeps adding features and products that make their core products more attractive, adding more value to our design capabilities.”

One of the most complex system elements of Innoviz’s lidar design are micro-electrical mechanical systems (MEMS). MEMS-based lidar uses micro-mirrors to directly control the light emission and focus of the laser beams for greater system accuracy. They also involve a complex combination of physical effects that are almost impossible to approximate with analytical methods. Understanding the interplay between physical effects requires Ansys tools, which are key enablers of Innoviz’s MEMS design. At the ideation stage, Innoviz uses Ansys tools to run ideation cycles before a single part is designed to understand how certain parts fit into the overall system architecture. These quick simulation experiments are used to explore different options and determine the right architectural design choice.

This content was first posted on the Ansys website.