EOS: An In-Depth Look Into Additive Manufacturing Part Qualification Strategies

What is qualification and why does it matter for AM parts?

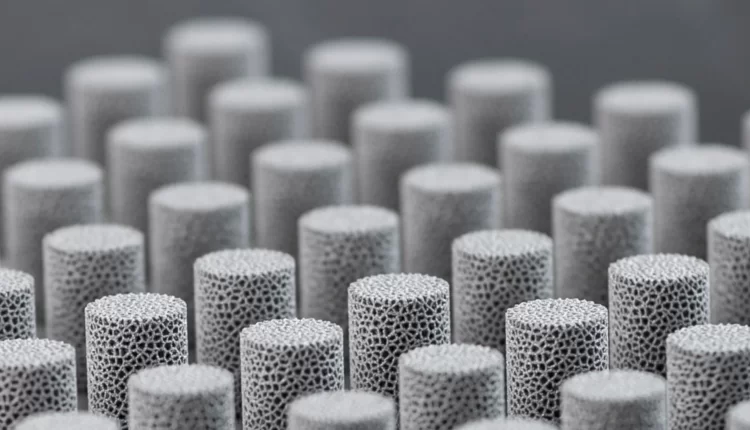

Quality assurance (qualification) is one of the critical requirements for additively fabricated parts intending to replace qualified structural and machinery components. The qualification process refers to the requirements that are tied to individual parts, machines, materials, and process parameters based on overall risk, and put into place to ensure the integrity of an application. As a result, qualification can be achieved by showcasing statistical equivalence based on testing many randomly selected parts across multiple builds and powder lots. Part qualification leverages the individual performance of a single part for a given material regardless of the machine it was built on.

Product certification and accreditation guidelines are in place for the parts manufactured conventionally (e.g., casting, forging), whereas AM components require a unique set of rules and certification schemas. With only a handful of standards focusing on inspection and certification for AM products, fast adaption to qualify AM parts depends on gathering evidence of processing history, process outcomes, and feedstock evaluation, amongst other sensor and manufacturing data. Regulatory bodies, research labs, and standard bodies are continuously publishing and updating technical guidelines to assist in the certification and qualification of AM parts based on the research and experience we are forging as an industry. Several steps are taken to ensure and demonstrate that printed parts adhere to the same qualification and certification requirements as their conventional counterparts.

What are installation, operation & performance qualifications?

Qualification of AM parts can be done in many ways. Based on different methodologies, one can extract three high-level phases on the path toward qualification.

- Installation Qualification (IQ) – the first qualification involves gathering evidence where all critical aspects of the process equipment and ancillary system adhere to OEM specifications. IQ typically includes two parts, Factory Acceptance Testing (FAT), usually done at the OEM’s site before the hardware is shipped, and Site Acceptance Test (SAT), performed at the customer’s site during the installation. The builds performed during FAT and SAT are generally identical to demonstrate performance equivalence before and after hardware shipment. Standard EOS procedure for IQ involves running generic and/or custom test jobs based on customer requirements for FAT/SAT and performing necessary safety checks and machine conformity tests.

- Operational Qualification (OQ) – this qualification is where necessary process controls are established to maintain stable material performance and demonstrate that material specification requirements can be satisfactorily met. It also involves building test jobs with static and/or dynamic test coupons to demonstrate effectiveness and reproducibility and to form the baseline for application design. These jobs are designed with the end application requirements in mind.

- Performance Qualification (PQ) – this involves locking the part-specific design, job layout, process inputs, and necessary postprocessing steps to obtain consistent printed parts over time. The first article inspection/testing results are often essential when applying for the certification requirements. Based on the volume of production parts, the concepts can be extended to calculate process capabilities and implement strategies for statistical process control to achieve higher robustness.

The challenges of qualification

The lack of clarity with AM qualification standards can be challenging since guidelines and procedures seldom help customers set up their qualification protocols. For example, over a dozen standards for qualification for AM parts are used for aerospace, automotive, and medical industries. By contrast, guidelines for qualifying AM parts used in semiconductor or oil and gas industries are limited and still being developed. If not implemented correctly, the qualification process could incur increased downtime and added test and printing costs, as each qualification phase demands considerable resources. Creating control plans for materials and processes, defining qualification protocols, and generating cost-effective test plans that produce safe and high-quality parts can be challenging without guidance from experienced AM qualification specialists.

Tackling part qualification

Qualification is a challenging step to tackle for customers both experienced and beginning their 3D printing journey alike. Although it can be done independently, it can cause delays in production, additional certifications, and increase time to market for organizations with multiple standardizations. The applied engineering and training unit at EOS, known as Additive Minds, has dedicated specialists for this step in the AM process. As ambassadors to additive manufacturing, preparing customers and mitigating the challenges of qualification are important steps in preparing outside organizations to leverage 3D printing to the fullest.

More about the Additive Minds qualification strategy

The Additive Minds qualification strategy relies on reducing the repeated testing of individual components and assisting customers in speeding the qualification timeline by incorporating the lessons learned over the past three decades – eliminating the reinventing-the-wheel experience for our customers. The EOS team engages with custom-made, critical-to-quality (CTQ), Process Failure Mode Effect Analysis (PFMEA) workshops that provide vital insights into customers’ readiness for the qualification. Additive Minds also infuses the use of digital tools, such as process simulations, advanced robotics, artificial intelligence, machine learning, remote monitoring, and augmented reality and virtual reality (AR/VR) with EOS printers to support customers developing a robust platform to enable the accelerated transition to qualified printed parts.

Qualification going forward

In the AM industry, a qualified part means repeatable, reproducible, predictable, and consistent part performance with the ability to scale for mass production. While AM technologies continue to mature, the emphasis for the next decade is on producing qualified parts for diverse applications in large quantities, which are crucial for this manufacturing method to be widely adopted by traditional industries.

If you are interested in discussing your organization’s qualification strategies process, please reach out to the Additive Minds team today.

Author: Yash Parikh, Ph.D., Process Engineering Consultant of EOS North America

This content was first published on the EOS website.