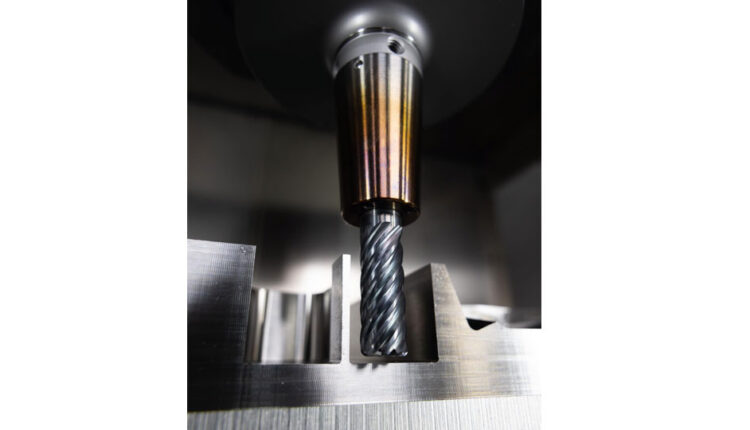

Walter Tools: More teeth – more productivity

Walter MD177 and MD173 Supreme solid carbide milling cutters for ISO S, P and M

With the MD177 Supreme and the MD173 Supreme, Walter is for the first time launching solid carbide milling cutters with seven cutting edges. Developed for the aerospace industry, their performance is excellent not only in titanium, but in steel and stainless steel too. The two Supreme tools are set apart from standard solid carbide milling cutters by their geometry, among other features. The version with seven teeth achieves excellent productivity, while its uneven pitch reduces vibration, ensuring excellent operational smoothness. The entire length of the cutting edge can be used, meaning that wear is relatively uniform – in turn extending the tool life of the milling cutters.

This statement applies particularly to the MD173 Supreme. This is because the roughing cutter was designed specifically for dynamic milling and for reducing machining time. Its cutting edges equipped with chip breakers enable excellent chip breaking, and therefore outstanding process reliability with high metal removal rates, as you will be familiar with from dynamic rough milling. This is advantageous, for example, for users with unmanned production processes. The MD177 Supreme finishing face milling cutter creates very smooth surfaces without “waterlines” because the entire length of the cutting edge is used during chamfering. As a package, the milling cutters therefore promise outstanding productivity and process reliability, with excellent surfaces in ISO S, ISO P and ISO M.

This content was first published on the Walter Tools website.