Star SU: The benefits of re-tipping and re-cutting PCD tooling

Fixed Pocket PCD milling and interpolating tools are designed and built as a complete one-piece product, combining a steel body and a holding interface. Additionally, PCD segments are brazed into the tool body. The PCD segments then go through the manufacturing process to meet the requirements of the finish tool geometries. This type of product is known in the industry as Monoblock tooling.

Re-tipping Process:

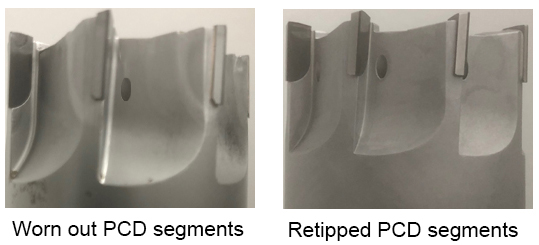

Once the tool completes its tool life cycle and the product is worn out, it is pulled from the manufacturing environment and evaluated. If the tool body is intact, the product goes back to a PCD tooling manufacturer to be re-tipped and brought back to original condition. This process offers significant price savings to the end-user as compared to buying a new tool.

The re-tipping process is done by removing the PCDs from the tool. The tool then goes through a cleaning stage and has new PCD segments brazed back into the tool. Next, it goes through the finishing process to meet finish tool requirements, is inspected, and is then returned to the end-user for its next manufacturing cycle.

Additional techniques for repairing PCD Milling/Interpolating Tools:

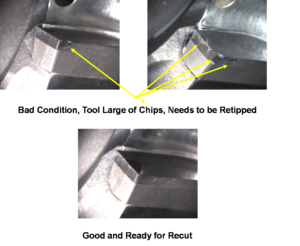

With today’s competitive manufacturing environment, there is an ongoing demand to drive additional cost down. At Star, we can offer additional savings for our customers by re-cutting, rather than re-tipping, when applicable. The savings comes from the fact that re-cutting eliminates the need to replace the PCD segments.

This process begins with our engineering team reviewing the project and establishing new reconditioning tolerances on the cutting tool print. This defines new minimum diameters and step length dimensions that meet the finish part print requirements.

If the tool was not originally designed and manufactured by Star/Neher, then we also evaluate the other supplier’s tool body to ensure it has proper clearances. In some cases, we need to rework this existing tool body to create the increased clearance required between the tool’s body and the finished PCD segments so that the tool can be re-cut successfully. If this re-work is needed, the tool will go through a re-tip process to remove the PCD segments, allowing our manufacturing team to re-work the body accordingly.

In most cases, after the PCD re-cut process, the tool needs to go back through the re-tip process to ensure that the finished PCD tool can still meet the finish part print conditions.

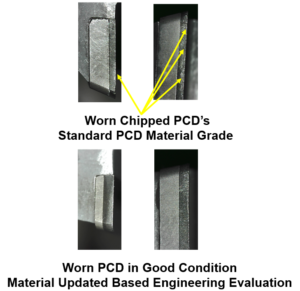

If we continue to see issues of PCD tooling being returned with chipped PCD segments, then our advance engineering group can evaluate the overall process and potentially recommend changing the grade of the PCD for improvements that allow successful re-cutting of the PCD.

Overall, re-tipping and re-cutting –when available– leads to increased cost savings.

__

Jamie Dunneback – National Sales Manager, Round Tool Divisions

This content was first published on the Star SU website.