Siemens: How Digitalization In The Automotive Industry Benefits Manufacturers

With the expectation of more autonomous features, managing the complexity of multiple domains must be reliable ensuring sensors can trigger a response in milliseconds.

To accomplish this, OEMs and suppliers require access to digitalization in the automotive industry that can transform the way they compete, collaborate and connect. Siemens Xcelerator software for industry is built to turn complexity into a competitive advantage, ensure companies have the software and services available when they need them and that they can forge their digital journey their way.

Digitalization in the automotive industry

Digitalization is a must for building the vehicles of tomorrow. Companies need to seek out ways that meet the challenges of scalability, compliance and collaboration.

Collaboration goes beyond traditionally siloed teams working together. It extends to the suppliers tasked with delivering pieces that are developed and tested in a secure and efficient way that integrates with the overall vehicle. This makes it easier and quicker to find and resolve design issues earlier in the process or even avoid these problems in the first place.

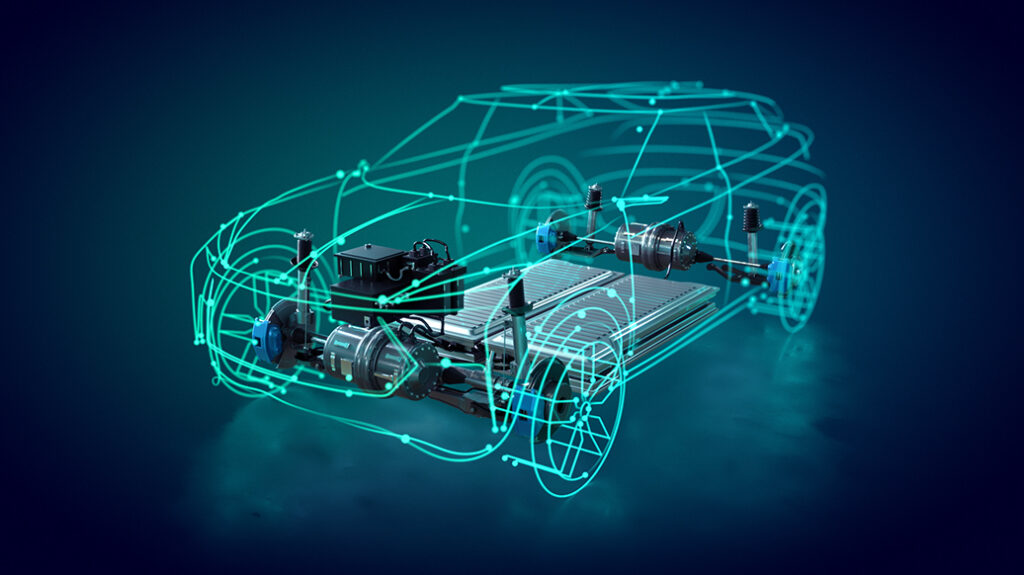

One of the most important things digitalization can do is improve the integration and collaboration between various engineering domains, which means software engineers can work more closely and efficiently within electronics hardware, electrical electronic systems integration and mechanical domains.

This level of continuous integration during the development process can further improve and optimize designs with increasingly tight time constraints. It ensures less time is spent on resolving issues during the integration of the various domains.

Digitalization also enables automakers to take a comprehensive model-based systems engineering approach. This digitalized process allows for a holistic system-level view of the vehicle during its development through connected digital tools. By capturing product requirements, performance targets, constraints and other information to form the product definition, the data received via simulation and tests can further enrich the digital twin of the vehicle and engage the entire ecosystem in a closed-loop environment.

Your digitalization in the automotive industry journey starts here

Migrating from the legacy approach can be very difficult, which is why it’s critical for companies to find a technology partner with the expertise to effectively use simulation and data management technologies to support your processes and engineering activities.

This approach allows companies and manufacturers to realize the true potential for digitalization and how they can transition faster and with fewer risks.

Where to begin depends on where you are.

Start in an area where you’re challenged the most within your business processes. By building upon those successes, you can then grow and expand into the other parts of the business to deliver end-to-end solutions.

There is no cookie cutter way, but rather it depends on the individual company’s situations and the problems they’re facing.

Siemens Xcelerator software for industry: accelerate your digital transformation journey

Siemens Xcelerator software for industry: accelerate your digital transformation journeyThat’s why the perfect solution can be found within the Siemens Xcelerator software for industry. All of its tools and services can be tailored to the needs of the organization. It provides simple access to the latest technologies that are easy to integrate, adopt, and build upon your current technological infrastructure.

The open technology is cloud-connected, which means teams can scale up or down based on the needs of the moment rather than being stuck with software that goes unused.

This content was first published on the Siemens website.