Sharpening skiving cutters for new EV transmissions: ANCA

Enable skiving cutter sharpening on ANCA’s TX and MX machines

Fossil-fuelled cars are set to become a part of history. Many countries have set a deadline for ending the sales of fossil-fuelled cars: France from 2040, the UK by 2030, and Norway aims to become the world’s first country to achieve this by 2025. Responding to green initiatives, and after billions of dollars have been invested in vehicle electrification, the automotive industry’s giants are pledging to stop making old-fashioned internal combustion engine (ICE) vehicles. Volkswagen plans for 25% of sales to consist of electric cars by 2025, Progressive General Motors is aspiring to stop making gasoline-powered vehicles by 2035, and Ford (Europe division) will go entirely electric by 2030.

For cutting tool manufacturers serving the automotive industry, the industry’s electrification is an existential challenge and a revolutionary opportunity. In 2017, 11.8% of cutting tool consumption was for automotive manufacturing. Machining time for pure electric vehicles (EVs) is estimated to reduce by 50-75% compared to traditional ICEs, resulting in overall cutting tool consumption decline as ICE vehicles’ production ceases.

The declining demand for cutting tools is a substantial threat, especially for cutting tool makers that heavily depend on the car industry; simultaneously, EV also provides many opportunities. The new skiving cutters required for the internal gears used in many new EV transmissions are significant.

45% of all gear production is for vehicle transmission. EV has changed the requirement for the gear industry. The high engine speed of up to 20,000 rpm means a higher gear ratio is required to reduce the speed for efficiency. The planetary gear system is more prevalent in the new transmission design. In a planetary gear set, the external gears need to be ground, which the current production process of hobbing and then grinding can easily cater to. The problem is with the internal ring gear. Traditionally, the internal gears are produced with shaping or broaching; shaping is slow while broaching relies on cumbersome tooling.

For EV, efficiency – as well as noise emission – is of much higher priority for customers. Gears for EV require greater precision and higher performance. The quality needs to increase from DIN 10 to DIN 6 for the internal gears; the gear industry sees hard skiving as the revolutionary process to produce the millions of internal ring gears needed for EV.

Driven by EV unparallel 28%~36% growth rate (see chart), the skiving cutter used in the skiving process is in high demand. Due to its complex geometry, producing solid carbide skiving cutters requires a series of technology and process development. Released in 2019, ANCA’s GCX Linear provides a complete solution for manufacturing DIN AA quality solid carbide skiving cutters – the highest in the industry.

Skiving cutters are classified as pinion cutters, consisting of the flank and rake face. After the flanks are produced, resharpening – or simply sharpening, as known in the industry – only grind back the rake face. These tools are expensive and designed to have a long tool life, typically 6mm to 10mm of resharpenable depth. During resharpening, the rake face is ground back by 0.3mm to 0.5mm each time, depending on the level of damage. There can be as many as 30 to 50 resharpenings during the lifetime of a tool. Following the growing trend of EV, there could be a need for hundreds of thousands of skiving cutters by 2024, which will equate to over a million sharpenings.

To enable ANCA customers to tap into this fast-growing market, ANCA released a new software package to sharpen skiving cutters and shaper cutters. Customers with MX and TX machines only need to purchase a software update and replace the standard probe with a ruby probe tip.

In the ToolRoom software package, the new purchase option ‘Pinion type cutter sharpening’ contains operations for digitizing and sharpening the two rake face styles: stepped rake face and conical rake face.

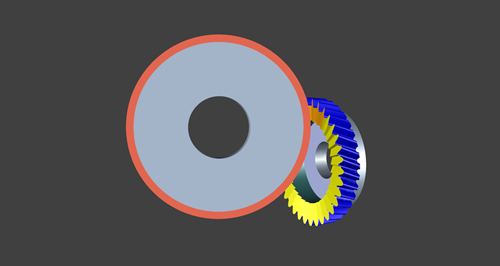

A conical rake face is part of a conical surface, defined by a rake angle and intersection with the flank to form the tool’s cutting edge. Sharpening a conical rake face requires an operation to digitize the end of the tool position, then regrind the conical surface with a 1A1 wheel. There is a plunge grinding method for the initial heavy grinding and oscillating grinding styles for subsequential resharpenings.

A stepped rake face is a planar surface defined by a rake angle and a lead angle. To resharpen stepped rake face, finding the tooth’s accurate index position and aligning with it is critical. ANCA software calculates the correct geometry to guide the ruby probe to find the right position. The process is automated, with no need for particular alignment and manual intervention. The sharpening of the rake face plane takes place on one tooth at a time, either with a 1A1 wheel for speed or a cup wheel for improved surface finish.

The resharpening package is available for MX and TX machines. With minimal hardware change, the MX can accommodate tool diameters up to 105mm. The TX is even more capable, with a larger working envelope and a more robust build, to fit a tool diameter up to 240mm. The hub type and disk type cutters can be mounted onto the collet with a fixture. The shank-type cutters can be clamped directly in the collet or with an adaptor for morse taper.

This content was originally published on the ANCA website.