Scantech 3D: How to 3D Scan Intricate Details with Handheld 3D Scanner SIMSCAN?

Electric tools, widely used in our daily life, are protected by plastic shells. These shells must be constantly upgraded to ensure the optimal use of tools. In this application story, we will show you how 3D scanning can help to improve the design.

Case background

The customer in this case has won its reputation for supplying electric tools. Because of its wide range of products, its plastic shells are featured in various shapes, colors, and finishes. These shells are mainly produced with thermoplastic.

This project is to capture geometric 3D data of the plastic shells so that engineers can draw insights from these data to optimize the design of products.

The data captured by 3D scanners can also be used for improving mold flow analysis, a technique that simulates the process of injection molding. By analyzing the data, engineers can have a virtual preview of how the preferred material will fill the mold cavity.

It helps them to have a clear picture of the factors such as shrinkage rate, fluidity, and thermal stability of materials. Consequently, engineers can evaluate the feasibility of the scheme to improve the design of the mold and product.

3D Solution

The products to be scanned are featured by complex details, irregular forms, deep holes. They hugely vary in shapes, finishes, and colors, which is challenging for measurement. To optimize further design, engineers must capture the geometric data with high accuracy.

Scantech provides a customized 3D solution with the portable 3D scanner SIMSCAN to fulfill this task.

High efficiency in capturing intricate details

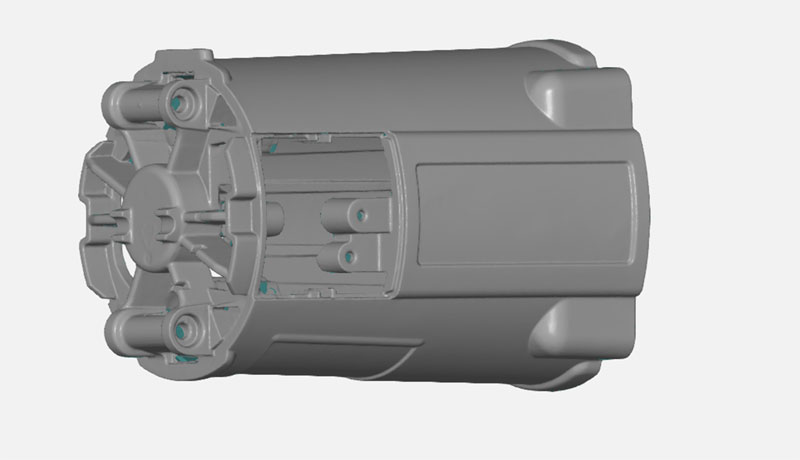

The plastic shells of the electric tools to be scanned have many complex features such as deep holes, gaps, and grooves.

The SIMSCAN performs well in capturing these intricate details due to its shorter distance of two cameras when compared to traditional 3D scanners. The shorter camera distance results in a smaller view angle, which ensures that its scanning view is not be blocked, shown as below.

In this way, when scanning narrow spaces, both of the two cameras of the 3D scanner can see the laser lines projected on the object. The shorter camera distance helps SIMSCAN to perform better when scanning the narrow areas like the grooves. See the picture below to find out how it performs.

When scanning a cylinder shell, technicians captured the general geometry of the shell with ultra-fast scanning mode. Then, he used ultra-fine scanning mode to capture various details. At last, deep hole scanning mode was used to capture the data of the inner surface of the cylinder shell. These versatile modes helped the customer to scan different features in an efficient way.

With an accuracy of up to 0.020 mm, SIMSCAN ensured the 3D data of these complex parts are precisely captured for further analysis.

Precise Measurement

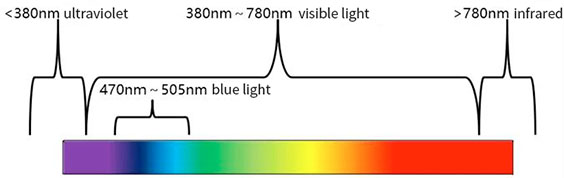

Blue lasers have a shorter wavelength compared to traditional red lasers, allowing for a stronger focus.

The molds to be scanned are of different colors. With blue laser lines, SIMSCAN has a strong anti-interference ability and can completely collect 3D data of products.

Complete and accurate data were obtained when scanning black surfaces, as shown below:

Efficient

With a measurement rate of up to 2.02 million MPS, SIMSCAN can scan a part with an average of 10 minutes. The complete 3D data captured can be imported to professional software and used for further mold flow analysis.

Lightweight

The 3D scanner, with a net weight of only 570g, allows users to carry out 3D measurements anytime and anywhere. You can perform scanning with just one hand, which will not cause much wrist fatigue.

Summary

The 3D digital solution successfully helped the customer to obtain the complete 3D data quickly and served as the basis for mold flow analysis to optimize the manufacturing process.

When scanning a wide variety of objects with complex shapes and different colors, SIMSCAN achieves outstanding performance. It is lightweight to use and powerful to scan refined areas and intricate details.

This content was first posted on the Scantech 3D website.