Rockwell Automation: Unlocking Production Hours with Digital Performance Management

Across the manufacturing value chain, a new framework for improving performance is emerging — one that connects digitally enabled factory processes to closed-loop continuous traditional process improvement (CPI).

Digital performance management (DPM) is an industrial information solution built in PTC’s ThingWorx platform that leverages familiar lean principles to transform how factories achieve higher levels of operational excellence. While the principles and many of the component tools are well established, the way they are brought together is groundbreaking. DPM collects data from automation and operator engagement identifies production bottlenecks and delivers operational equipment efficiency (OEE) calculations. Combined with time loss Pareto analyses, DPM enables better decisions on where to invest scarce resources in the closed-loop continuous process improvement (CPI) initiative. DPM helps identify hidden opportunities for performance improvement that can lead to double digit improvements.

Plenty of Data, Not Enough Insight

The problem with data is no longer a lack of availability, poor accuracy or timeliness. Factory executives are awash in timely, accurate data. Rather, there’s a significant gap between data and useful insight. Many manufacturing organizations have a hard time figuring out how to manage, sort, organize, curate and to deliver valuable insight. They need their data to enable and support better decision-making.

DPM ingests operating data, analyzes and presents it in ways to make problem identification easier and selection among corrective action alternatives more efficient.

Closed Loop Problem Solving and Production Operations

Identifying bottlenecks in a consistent, repeatable way is difficult to do manually and is labor intensive. DPM for PTC provides a set of tools that largely automates the collection of data and identification of the production line’s pacesetting operation.

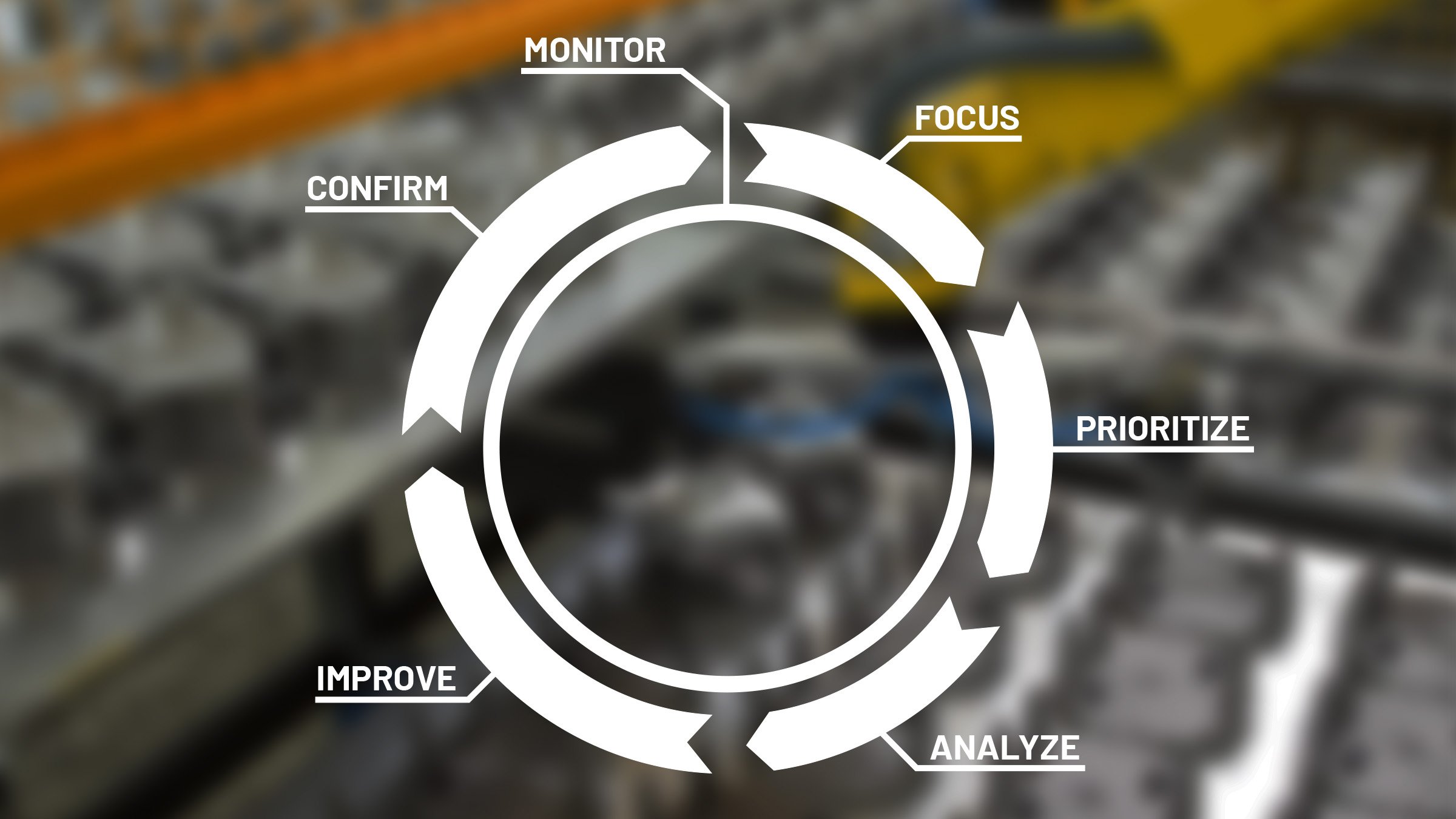

To understand DPM, think of these steps:

- Monitor: Constantly measure what’s going on in a factory line

- Focus: Find the production pacesetter. Identify and rank bottlenecks

- Prioritize: Identify the highest impact performance issues that demand focus

- Analyze: Determine the root causes and characterize the sources of loss in the operation

- Improve: Put a plan in place to fix it

- Confirm: Monitor the fix and make sure the plan fixes the problem.

- Repeat

An Operating System for Continuous Improvement

DPM is an operating system for continuous process improvement, through its collection of five distinct tools surrounding a powerful production control monitoring capability – all built on ThingWorx. These are the digital data tools that are helping to transform factory data into valuable performance insights.

This content was first published on the Rockwell Automation platform.