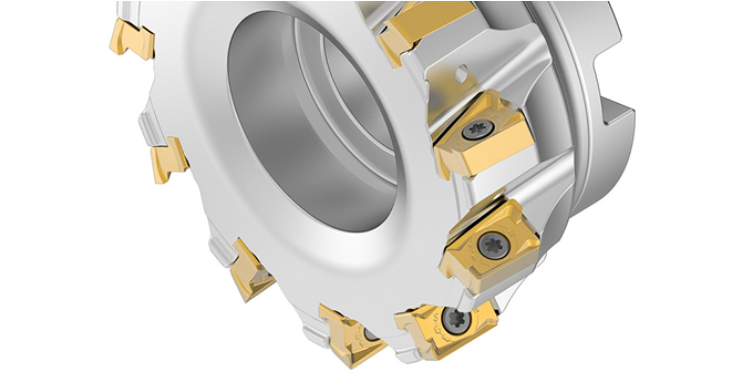

MILL 4-15™ Indexable Shoulder Milling by Kennametal

Excellent surface quality and higher metal removal rates

The unique design allows to the application of the tool in multiple passes, called “step down”.

Most tools leave tool marks with every pass they take, resulting in unsatisfactory or low-quality wall finishes. This usually requires another finishing pass at the very end of the process.

Mill 4-15 eliminates that finishing pass with an additional tool, saving time and money.

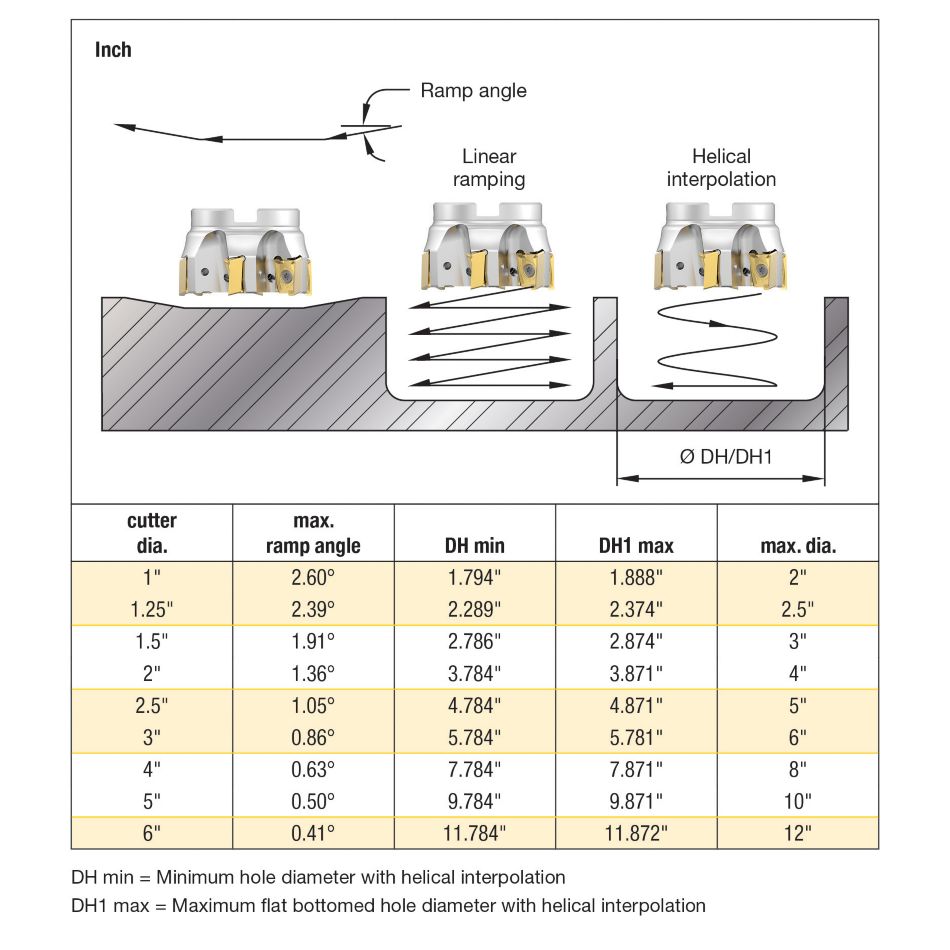

The SGE-R geometry adds to the capabilities of the Mill 4-15 series, enabling ramping operations and helical interpolation.

SGE-R geometry featuring a redial clearance to support chip formation in ramping operations.

SGE-R geometry with strong edge preparation for ramping and helical interpolation.

Double-sided insert 4 strong cutting edges per insert.

90-degree shoulder milling with excellent wall and surface finish capabilities.

Applicable in steel, cast iron, stainless steel, non-ferrous materials, and high-temperature alloys.

Ramp Angle Application Recommendation