Meet Horsepower INC: 2020 #PARTPRIDE Grand Prize Winner, A Doosan Customer

HPi is also an unabashed Doosan Shop, with nine active models currently on the floor. In the summer of 2020, the company entered #PartPride, our social media part-making competition. The work was good enough to take the 2020 grand prize, besting nine other monthly winners to take the top prize. We caught up with HPi to get their story, hear how Doosan has helped them, and talk about what the future holds.

About HPi

If you know anything about Horsepower Inc. (HPi), you know they go hand-in-hand with Harley-Davidson™. The Pennsylvania- and Indiana-based shop was the first company to manufacture an aftermarket throttle body and intake replacement for Harleys. They’re a leader in v-twin fuel injection, serving over 300 dealers in the U.S. and worldwide.

Since the company was founded in 2002, Harley has changed its fuel injection system several times. Whenever it happened, HPi has adjusted quickly thanks to their machining expertise—and the fact that each one of them rides Harleys has contributed to their success. They react to Harley’s changes faster than anyone else, staying OEM-compatible in the process.

“Every day, there’s something different in manufacturing. There’s never a dull moment in a fast-paced shop like this,” said Mary Jo Light, Owner of HPi. “I used to be a school teacher so I like noise, and I just love the sound of machines running. It’s music to my ears.”

HPi and Doosan

Doosan has been part of HPi’s story from the start. The shop recently retired a Mynx 500 and a Lynx 200, both of which ran like clockwork for just under two decades. There are nine active Doosan machines on the floor now, and Mary Jo knew them by heart when we asked.

- Lynx 200 x 2

- PUMA 240MF

- Lynx 2100

- DNM 400HS

- PUMA GT2100M

- MV 4020LS

- PUMA D400

- Lynx 220LM

“The PUMA 240MF and the DNM 400HS are my favorites,” she said. “The DNM is a Cadillac; easily our favorite machine in the building since we got it in 2012. We run it at 10 to 12 thousand RPM. It maxes out at 12k, so we really run that thing two shifts a day.”

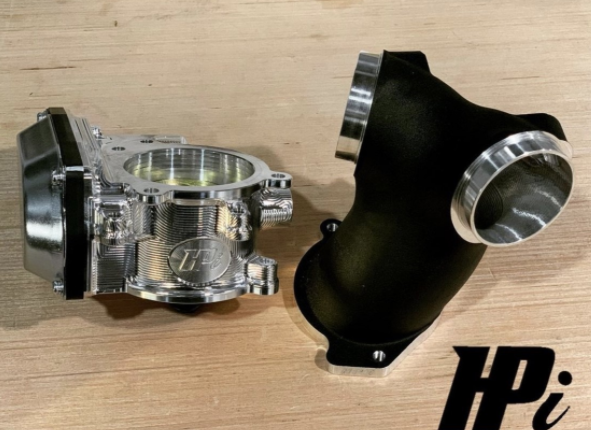

The Winning Part

The gorgeous throttle body HPi made is 3.5” x 4” billet aluminum, which takes about two hours of machining from start to finish. The DNM 400HS and DMV 4020 collaborated to get the part done.

“The scalloped finish we have on there is done purposely for aesthetics,” Mary Jo said. “Some of our customers anodize them, which tend to match with the color of the bike. All the options we offer keeps us ahead of the competition. Anodized, satin, chrome, and a lot more different options.”

All About Allegheny

HPi has been a Doosan Shop since it opened its doors, and that’s because of its great relationship with Allegheny Machine Tool. “They’ve just been awesome,” said Mary Jo. “Bruce was the first person I met there. He was a great man. Dan is in charge now and he’s done a great job. Their service department has been fantastic. We’re really pleased with their responsiveness. At some point, HPi could have been the Doosan showroom in the Lake Erie area.”If you, like HPi, make industry-leading parts, there are industry-leading machines with your name on them. Talk to your local Doosan distributor today about what you’re working on, and they’ll have recommendations for you faster than you can say done-in-one.

This content was originally published on the Doosan Machine Tools website.