In their production, manufacturing companies also use customer-specific measuring solutions such as those offered by the Millimar modular product family. They do not necessarily have to replace these after years of use but can update them with a measuring computer-based standard measuring software.

This provides customers with an economical way to keep their measuring devices up to date with the latest technology at all times. This is because standard measurement software does not have to be developed specifically for existing applications. It offers flexibility through the ability to add simple user-defined routines. This allows it to deliver reliable measurements while meeting the requirements for Industry 4.0, i.e. the digitization of industrial production. With the Millimar Cockpit software, Mahr has exactly the right product for these requirements in its portfolio.

Industry 4.0: Digitization of measuring equipment as well

Regardless of the measuring task, customer-specific measuring solutions have proven themselves for many years to increase productivity directly in production. The development of this measuring equipment follows physical and metrological principles that, by their very nature, do not change. What has changed, however, is the ever-increasing need for measurement data and information. The world is undergoing a digital transformation, and with it, modern technologies are increasingly shaping the manufacturing industry. The vision of Industry 4.0 announces that production systems and machines must be able to continuously communicate and adapt based on the data they collect. It follows that measuring devices in production must also be capable of exchanging information and providing it to the user about the ongoing process.

Measuring computer with standard software offers comprehensive advantages

Mahr has already digitized all types of measuring equipment: Handheld measuring devices such as the Millimess 2000 W (i) and 2001 W(i) precision pointers, mobile roughness measuring devices such as the MarSurf M 310, or complex machines such as the MarShaft SCOPE 600 plus 3D for shaft measurement. They can all perform demanding measurement tasks and exchange measurement data quickly. In addition, PCs are widely used in industrial production and are employed in almost all manufacturing, assembly and quality areas. Although PCs are rarely necessary for standard measurements, virtually every application can be improved with PC-based measurement software.

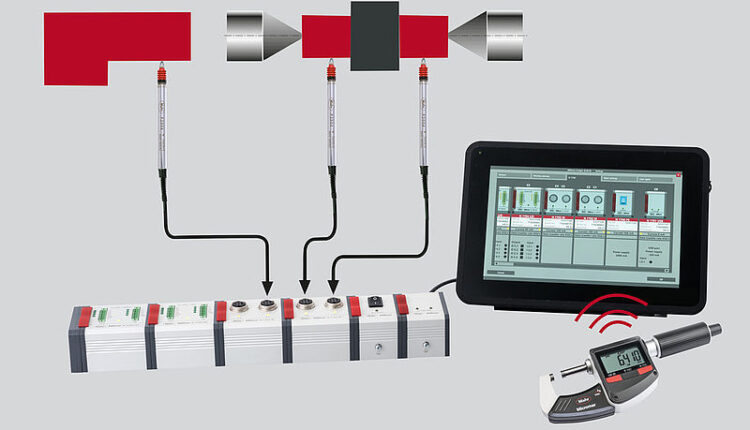

In contrast, the use of special measuring computers such as the Millimar C 1750 PC in combination with a customized measuring solution offers greater advantages with simple operation:

- A measuring computer processes many individual measuring points by integrating measuring channels for different sensor types into a basic computer.

- These measurement channels allow it to evaluate several measurement sensors simultaneously instead of a series of individual ones.

- In addition, it provides the operator with a visual display of the acquired and evaluated measurement data.

- Since it is networkable, its measurement results can be seamlessly integrated into modern production.

Thus, the measurement computer serves to display, acquire data, classify the results and control the overall measurement process while information is exchanged in the background.

New functions for existing measuring solutions – reliable quality

For up-to-date data acquisition, it is not enough to just receive the measurement results. Often, the operator needs to add additional information that is not directly related to the measurement process – and to do so as simply as possible. Information such as the serial number or production date code of a workpiece, the identifier of the processing machine or the name of the production employee is required so that a measurement can be clearly assigned to a data record. On the one hand, the acquisition of this information can be so simple that the operator can enter it on the measuring computer during the measurement. On the other hand, the acquisition can be more demanding if, for example, the operator has to scan data matrix codes on the workpieces or bar codes on the documents accompanying the components.

Further information identifies the measuring device itself, its valid calibration and thus its measurement suitability. This documents and ensures the traceability of the measurement and thus represents an important criterion for quality assurance. Finally, the measuring computer must make this data available to the company in a suitable form. In Industry 4.0 systems, the measurement information therefore usually flows into a central repository, i.e. a directory or archive such as an SQL or Access database that manages the data, or directly into an ERP system. These are extensive requirements, which the Millimar Cockpit software meets: It allows measurement data to be formatted and configured to be integrated in the right format in the right place – ensuring maximum effectiveness in data usage.

This content was first published on the Mahr website.