Ligna 2023: Wood Cutting Tool Manufacturing Made Easy With ANCA Technology

ANCA is known to tool manufacturers for providing a large variety of solutions, from robust manufacturing of standard round tools to a range of special tools, all with the respective process equipment and automation. ANCA’s machines, software and automation have been enhanced continuously, delivering technical expertise to a range of fields of application and industries.

At Ligna, Hannover, global visitors can experience what this means in the field of woodworking. Visit ANCA at Stand A60 in Hall 27 to see:

- A clever, cost-effective two-in-one solution for blades and round tools on the FX machine series

- A hybrid electro discharge grinding machine (EDG series) with a high performance, process-controlled spark erosion generator

“ANCA’s tailored woodworking solutions are efficient and cost-effective solutions for this specialist market. At Ligna we are sharing how ANCA’s technology supports woodworking tool manufacturers with application flexibility,” says Martin Winterstein, ANCA Europe General Manager.

FX woodworking setup allows for flexible production of blades and round tools

On the affordable FX grinding machines, ANCA has developed a solution that provides more flexibility and capability for unattended production of wood tools. Special tooling systems for FX5 and FX7 machines offer the ability to easily change automated production between woodworking profile blades, used to form skirting boards and architraves, and solid round shank tools such as routers and drills used in production of furniture and cabinetry.

Two options for the work holding are offered: a blade chuck to hold flat profile blades, or a PremierPlus collet chuck for holding round shank tools. Both systems are actuated with the same pull stud mechanism, so switching between the two systems is done in minutes.

ANCA completes the package with a suite of flexible and user-friendly software options to cover diverse tool production needs. The blade grinding software includes blank and finished profile definition with DXF import, slice roughing for fast removal of bulk stock material before the final profile relief passes.

The compression router software gives complete flexibility to program up and down cut sections ensuring correct overlap on two or more flutes. Standard endmill and drill software packages are easily adapted to wood cutting tool geometries including up and down cut spiral routers and drills. Profile software opens scope to also manufacture brazed carbide profile routers.

ANCA’s customer FAMEG from Radomsko, Poland is one of the biggest chair manufacturers in the world. They insourced their production of profile blades and round tools with an FX and have seen significant results: “Our production requires using specialised tools that have unusual dimensions. Obviously, we also use standard cutting tools, but the majority are specials,” says FAMEG Product Manager Ireneusz Idzikowski.

“The machine has solved a lot of production problems. Now we can access cutting tools when we need them. It means we have stock or can manufacture the required cutting tool pretty much immediately, which wasn’t possible until now. It completely changed our work quality production wise”, continues Idzikowski.

EDG: ANCA SparX Erosion Generator automatically detects PCD grade and delivers 30-50% reduction in erosion Cycle time

The advantages of PCD tools for wood applications are widely known: higher feed rates, longer tool life and resharpening options, high edge and surface quality on the workpiece side provide cost and flexibility improvements.

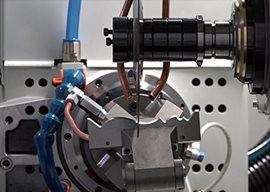

ANCA’s EDG machine, with the new SparX Erosion Generator, Intelligent Adaptive Control (IAC) and Adaptive Spark Control (ASC), is designed for producting of a variety of helical and round PCD tools.

All the components and process technology were developed and are produced completely inhouse at ANCA. With the erosion generator’s exceptionally high power range covering heavy roughing and fine finishing, the IAC enhancing erosion speed and surface finish by controlling the erosion gap, and the ASC optimising the energy level of each spark for stronger cutting edges, the EDG is a game changer.

A 30-50% reduction of cycle time against comparable machines and unseen surface qualities down to Ra < 0.1µm and Rz < 0.5µm are the result of the extensive development work at ANCA. At Ligna, the EDG demo will show optimized processing of a multi insert shear tool cutter.

This content was originally published on the ANCA website.