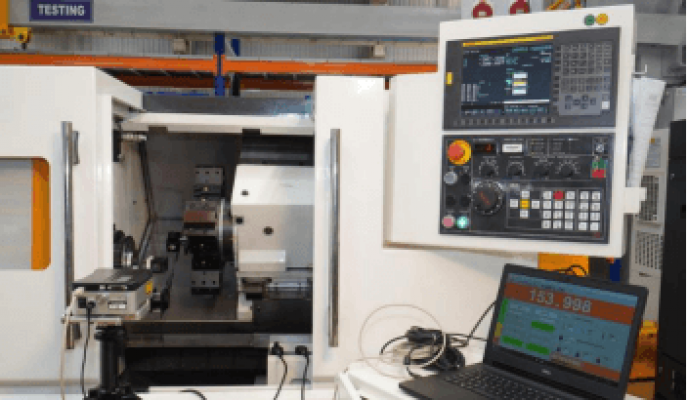

Is your Machine Tool within Tolerance? Be sure with Laser Calibration

How do you document that your CNC machine tool is within tolerance? Ball bar or laser calibration services, the bottom line is your machine tool needs to be regularly screened and corrected to expect dependable performance from your machine tools.

Machine tools need to maintain a standard of precision and accuracy for consistent production. With time and wear, machine tools are bound to develop discrepancies in inaccuracy. According to a study by the National Centre of manufacturing sciences, the machine tool itself accounts for 40% of all part quality problems. Correcting these will cut down accuracy and part quality problems significantly.

To identify the level of deviation and to bring it to an appropriate standard calibration is needed. We have discussed how ball bar calibration are beneficial, but do you know how Laser calibrations are now becoming an essential step of the ISO 9000 quality standard requirements?

Regular calibration ensures machine tools maintain maximum performance and are within tolerance. The reason for these programs is that if the process is accurate, then the part will be accurate as well. The result is higher quality parts, lower costs, and shorter delivery times.

When it is done:

Laser calibration should be performed after any major mechanical work is done to a machine’s axis. This includes new ball screws, gearing, or feedback changes. If your machine must be used to perform accurate work, then you should consider laser calibration. The laser not only shows you how accurate your machine is but can be used to compensate for inaccuracies.

How it is done:

Laser interferometer enables measuring distances down to submicron levels with the wavelength of laser light as the foundation. With suitable optics, a thorough check on a machine checks like linear positional errors, pitch, repeatability, reversal errors yaw, and straightness errors in slide motion and squareness among axes can be made for positional and geometrical accuracy. In concurrence with a Rotary calibrator, Laser Calibration System can be used to calibrate the Rotary axis also.

How it helps:

1. Faster data capture

Laser Measurement Systems have higher data capture speeds of up to 5000 Hz, which are used for dynamic measurements like Velocity and Acceleration of slides, which reveal drive errors and stick-slip motion. These systems can also be used for monitoring various machine elements for their performance.

2. Online and instantly available data

Laser calibrations are performed with the help of computers. When the data is captured, results are instantly available online and helps in applying the mechanical adjustments on the machine and software compensation in the control system.

3. Checking alignment

Ensuring proper alignment of the machine before calibration is important before starting the calibration process. The services include alignment of guideways, guide rails, bores, guide tracks, etc.

4. Making accurate adjustments

With all the support of the technology of laser calibration, the corrections made on machines can be trusted to be the most accurate. This reinforces your machine’s capability to produce accurate components.

Whether it is laser or ball bar calibration for your machine’s tools, Micromatic 360 offers the most suitable solution to your calibration needs. Contact us immediately to know which would be the perfect fit for your requirements.

This content was originally published on the Ace Micromatic website.