How WE Fabricate the Infrastructure Sector

The infrastructure sector includes power, bridges, dams, roads, and urban infrastructure development. The infrastructure sector is a key driver for the Indian economy. The sector is highly responsible for propelling India’s overall development and enjoys intense focus from the Government for initiating policies that would ensure the time-bound creation of a world-class infrastructure in the country. The infrastructure sector includes power, bridges, dams, roads, and urban infrastructure development. India was ranked 44 out of 167 countries in the World Bank’s Logistics Performance Index (LPI) 2018. India ranked second in the 2019 Agility Emerging Markets Logistics Index.

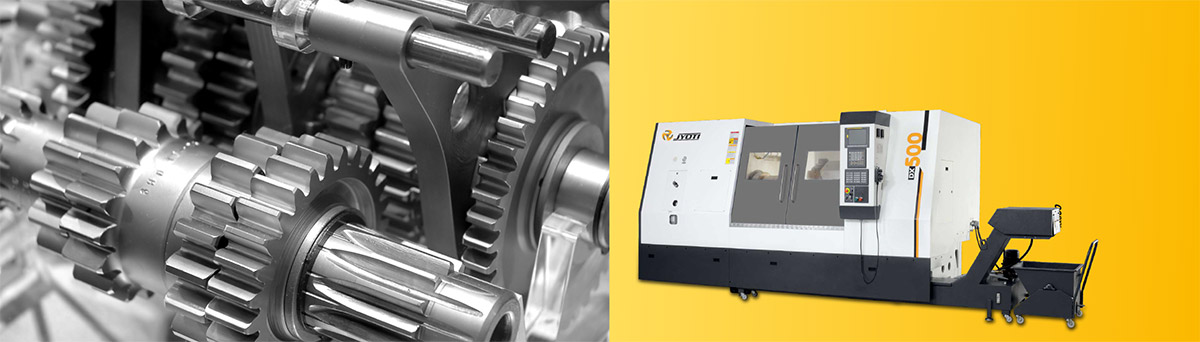

How exactly are CNC machines used in the infrastructure sector?

The tools and equipment used to construct things, as well as the materials used to build them, inherently involve CNC machining. It’s a part of most building processes by nature of the wood, stone, nails, screws, and other items used to create a structure. It might also be the answer to a desired architectural style, such as relief statues, or it could be needed for safety compliance or aid, such as with textured handrails.

Jyoti CNC’s role in the infrastructure sector

DX Large series –

The tools and equipment used to construct things, as well as the materials used to build them, inherently involve CNC machining. It’s a part of most building processes by nature of the wood, stone, nails, screws, and other items used to create a structure. It might also be the answer to a desired architectural style, such as relief statues, or it could be needed for safety compliance or aid, such as with textured handrails.

VTL series –

To meet the requirement of heavy engineering industries such as Oil & Gas, Earth Moving, Automobile VTL series machines delivers their best. Graded cast iron bed and column assure thermal stability and better machine life accuracy along with great rigidity, stability, and performance. Box type construction, heavy-duty spindle, high-speed bi-directional servo turret, and wider box guideways assure vibration-free cutting. VTL finds its wide application for machining of bigger diameter heavy components like wheels in the Infrastructure sector.

NX nvu Series –

The Series developed on double column structure and greatly increased working envelop concept permitting machining large-size heavy component and a wider range of tool length to be accommodated in the same setup. The series is available with greater load-carrying capacity and the option of the horizontal head for 5-face machining. Z-axis is hydraulically counterbalanced to improve stability. Machining of the complex workpiece such as Structure parts, Heat exchanger plates finds application with the series in the infrastructure sector.

At Jyoti, we value our cutting edge technology and we like to share it through various industries to make India as advanced as it can ever be. We completely support our PM’s “Atmanirbhar Bharat” mission and we regularly make advancements to complete his vision. Our machines are the key to making India’s infrastructure sector completely “Atmanirbhar”! improve stability. Machining of the complex workpiece such as Structure parts, Heat exchanger plates finds application with the series in the infrastructure sector.

This content was originally published on the Jyoti CNC website.