Hexagon: Smart additive manufacturing offers the route to lower unit costs

A new whitepaper from Hexagon takes a deep dive into this topic and many others, but here we focus first on the influence of smart technology solutions on costs within AM.

Getting it right first time

The design phase offers the most significant potential impact to cost reduction, as this is the point from which the rest of the production process radiates. Decisions made during the design phase have a critical bearing on overall costs, from the choice of materials, to the geometries of the product, to the requirements after printing. This makes the choice of tools used to support this stage of the process equally critical.

CAE (Computer-aided Engineering) software that can make the design process smarter brings the ability to optimise the initial design instantly. This removes the need for iterations before settling on a geometry that delivers optimal weight and strength to the structure without the need for additional human input. Automated design elements such as these get you from screen to machine quicker, again reducing labour costs and material waste along the way.

Tools made for the task

Anyone who has attempted to use a tool for a very specific purpose that has been designed for a completely different task will know that although it is theoretically possible, there is an element of risk that is rarely justifiable. You find yourself compensating so much for the design shortfalls that despite perhaps succeeding in completing the job, you realise that next time it would be sensible to get the right tool instead!

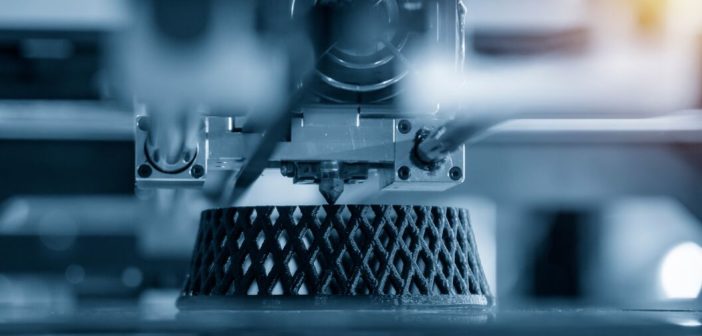

This holds true for CAE software that has been designed specifically for use in AM production, which requires the ability to work with detailed and highly complex structures that only additive processes can manufacture. Geometry freedom is one of the crucial benefits of AM and it is vital the supporting software is able to harness that power.

Material selection

As the AM industry has developed, the range of materials available for use has broadened – from polymers to metals and ceramics – offering more opportunities for utilising the technology in end-use products. Making the right choice of material is another important decision for overall unit costs, and there are many, many considerations to be made at this point, with initial production cost just one part of it.

Each material has its own characteristics, benefits and shortcomings. There is, of course, no one-size-fits-all material that can deliver optimal cost and performance across every category, so the ultimate decision on material is about finding a balance. Which material offers the right weight, durability, texture, sterility, adhesive qualities, temperature performance? …and many others.

Intuitive, automated design processes make these decisions faster, reducing time-to-production and minimising costly errors.

End-to-end solution provider

Hexagon is an expert partner for AM manufacturers, providing smart solutions that ensure software applications and manufacturing equipment operate seamlessly and as autonomously as possible.

Software such as MSC Apex Generative Design offers manufacturers the ultimate experience of smart generative design within an AM setup, while Hexagon’s SFx platform enables smoother, more efficient transfer of data across the various AM production processes, making that data work harder for lower overall costs.

The new Hexagon whitepaper, ‘End-to-end solutions for smarter additive manufacturing’, delves deeper into these topics, highlighting the enormous scope for improving process efficiencies which will ultimately lead not only increased product quality, but also lower costs. Download the whitepaper now to discover how Hexagon’s portfolio of AM solutions can optimise your manufacturing technology and processes, powering AM into a fully-industrialised future.

This content was first posted on the Hexagon Manufacturing Intelligence website.