Hexagon automates complex 6-axis production of large, heavy parts to improve operational efficiency

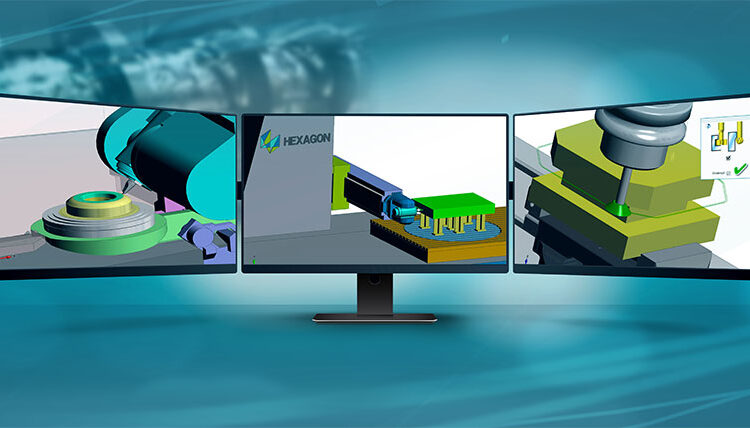

New computer-aided-manufacturing (CAM) technology introduced today by Hexagon’s Manufacturing Intelligence division makes it possible to efficiently use complex 6-axis milling machine tools to produce large parts for a variety of industries and applications. The specialist programming tools provide accurate simulation and generate efficient 6-axis toolpaths to ensure that the advanced machinery can be used to its full potential for increased productivity.

The ability to machine components of any size in a single operation increases efficiency, but it is especially beneficial when machining large parts because it eliminates the need for the labor-intensive repositioning of heavy and cumbersome workpieces. Ideal for cutting large components, 6-axis machine tools are often used to produce parts that can measure three meters or larger in diameter, including jet-engine containment cases that ensure passenger safety or parts for the energy and marine industries.

The new tools introduced in Hexagon’s EDGECAM software focus on 6-axis machines equipped with two rotary axes on the head and one rotary table, where this sixth axis enables milling tools to machine all sides of a large part, including areas that are otherwise impossible to reach without repositioning workpieces. The new dedicated 6-axis tools provide greater toolpath control and more accurate simulation of processes, reducing the need for expert intervention on the shop floor, improving the utilization of advanced machinery, and avoiding the risk of costly damage.

“The ability to perform seamless ‘one-and-done’ operations with 6-axis machinery enables manufacturers to produce massive and often quite challenging components without the burden of underutilized machinery or over-reliance on expert intervention,” said Miguel Johann Product and market manager, Hexagon’s Manufacturing Intelligence division. “You may have the most sophisticated machinery in the world, but without software that can harness its strengths, it can be very difficult – If not impossible – to reap its true potential.”

EDGECAM improvements also provide greater flexibility for 5-axis milling by offering tools that allow computer-numerical-control (CNC) programmers to select the level of automation they prefer when creating toolpaths. Using these tools, CNC programmers can choose to automate toolpath generation, manually create all toolpaths, or generate toolpaths using a combination of automated and manual tools. The ability to customize programming preferences increases control over exactly how parts are machined, helping users cut programming time on tasks that are simple to automate and making it easier to work more closely with complex toolpaths when needed.

Productivity is also improved with rough grooving operation optimization that eliminates unnecessary machine movement, resulting in a reduction in a cycle time of up to 60 percent. When enabled, the configuration ensures that the system will recognize the shape of irregular stock when needed. By taking the true shape of stock into account, the software helps users to avoid the generation of surplus toolpaths that lead to unproductive ‘air cutting’ when the program is sent to the machine tool.

EDGECAM now makes it easier to execute helical toolpaths, offering manufacturers tighter and more efficient machining than is offered by the ramp approach and opportunities to extend tool life with smoother and less damaging operations. Users need only define a minimum helix value for roughing operations; then, the software ensures parts are cut using a helical tool pattern, and the toolpath will not revert to a ramp approach. Computer performance optimizations also now significantly reduce programming time, generating roughing toolpaths two to three times faster than previous software for both wireframe and solid models.

Waveform turning ensures that cutting tools maintain constant engagement with the material, as well as a constant chip load to extend tool life, but can result in long NC code programs. A new option reduces the amount of numerical control (NC) code generated by up to 75 percent by converting line segments into fitted arcs that require less NC code to program. Users benefit from smoother waveform toolpaths and, therefore machining, and faster-executed code that is also shorter so that it runs effectively on older machine tools.

Interoperability with Hexagon’s CAM portfolio benefits EDGECAM users working with 3-axis milling operations. They can now test and optimize programs in Hexagon’s NCSIMUL Essential machining simulation software. Full machining assemblies, including tooling data, are imported directly into NCSIMUL Essential, where the programmer can dynamically interact with toolpath, identify code being simulated, interrogate and measure workpieces, and compare and analyze stock.

This content was originally published on the Hexagon MI website.