Hexagon and Stratasys partnership unlocks aerospace innovation and reduces part lead time with certified design-to-3D-print solution for plastics

Hexagon’s Manufacturing Intelligence division has announced a new solution with Stratasys, a leader in polymer 3D printing solutions, to help manufacturers in the aerospace sector boost confidence in the performance and safety of 3D printed plastic components and compress time to market. Through the virtual engineering and manufacturing support provided by the partnership, customers will be able to reduce a two-to-three-year timescale of designing and testing a part to six-to-nine months.

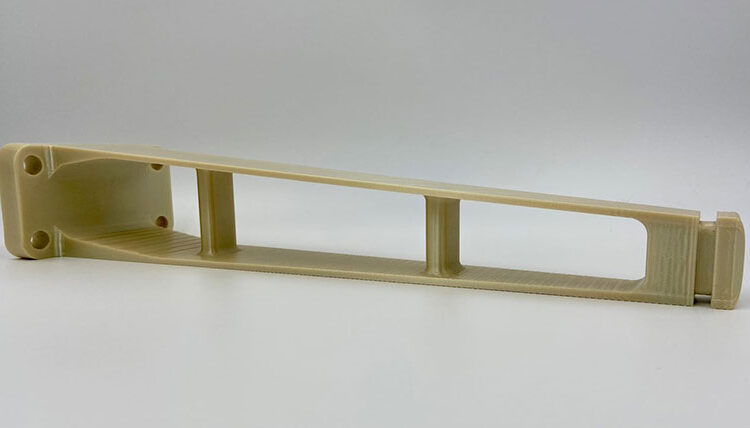

Through the new partnership, users of Stratasys’ ULTEM™ 9085 filament can now use Hexagon’s Digimat material modelling software to predict how printed parts will perform. ULTEM™ 9085 filament is used to produce parts for aircraft cabin interiors, such as bracketry, pieces for cable routing, covers and duct components, all of which are required to meet stringent certification, for example around flammability and toxicity. Airbus has used FDM™ technology in these applications dating back to 2014. Some customers also use the material in cosmetic aircraft interiors, such as Diehl aviation, which has used it to create curtain headers that divide cabin classes for the Airbus A350.

In aviation, the need for the material to meet certification standards is paramount. ULTEM™ 9085 resin is a flame-retardant, high-performance thermoplastic with a high strength-to-weight ratio, excellent heat resistance and high impact strength, and possesses favourable flame, smoke, and toxicity (FST) characteristics. The material modelling software provides engineers with a validated tool for analysing how this material will perform mechanically in a product design when printed with two compatible printers.

Using Digimat, engineers will be able to predict how parts made from ULTEM™ 9085 filament may behave when made using approved Stratasys printers. This is made possible through a highly accurate virtual material model jointly developed by the two companies through physical testing that includes detailed information about the material’s internal microstructure. The software’s process simulation capabilities help manufacturers avoid defects such as the delineation of warpage of a part and analyse the print time and material cost for the proprietary printer toolpaths of these machines to achieve an optimal result.

The solution gives aerospace engineers a number of benefits:

Increased confidence – Aircraft need to meet stringent regulations, and manufacturers have to convince and prove to regulators how a part will perform. While this has previously meant years of testing, now – through Digimat – they have access to a validated analytical tool that engineers can use to predict a part’s behaviour with confidence.

Faster speed to market – By improving understanding of material performance and reducing the number of physical prototype iterations, the timescales of the development and introduction of new parts – and therefore aircraft – can be significantly compressed, accelerating innovation.

Better understanding – Until now, engineers have been unable to understand how the material properties apply toolpath by toolpath, layer by layer on a complex geometric part. This has led to time consuming and expensive testing processes, using datasets based on the destructive testing of material coupons rather than real part geometries, meaning that testing never delivers full confidence in the material’s performance.

In addition, since they can explore more iterations of a part in a shorter amount of time, engineers can gain a greater understanding of what will work on the market.

Sustainable design – Engineers can validate that a part can be 3D printed and make optimal use of materials to lightweight aircraft or spacecraft.

Guillaume Boisot, Head of ICME, Hexagon’s Manufacturing Intelligence division says: “The aerospace industry is continuously pushing the boundaries of performance and innovation, but current confidence in the performance of additive manufactured parts is mostly limiting its application to highly specialised metal parts. We are excited that this new development in our partnership with Stratasys will help compress the design and testing phases and improve understanding of plastic behaviour and speed up innovation across the sector.”

Scott Sevcik, Vice President, Aerospace Business Segment for Stratasys adds: “The dual needs to make complex parts lighter and produce low volumes economically has meant that aerospace has pulled 3D printing towards production and put the sector ahead of the curve in use of the technology. But this also means it’s the first industry to identify several challenges, a key one being the need for a digital toolset to provide confidence in 3D printed parts. Our partnership with Hexagon is a big step forward in solving that, as it gives engineers the same upfront design intelligence for 3D printing that they have for traditional processes.”

The virtual engineering solution can now be accessed by customers of the Digimat material modelling software. Stratasys customers can request access to detailed proprietary material cards through its Materials Exchange capabilities and import toolpaths directly from their Stratasys Insight software.

This content was originally published on the Hexagon MI website.