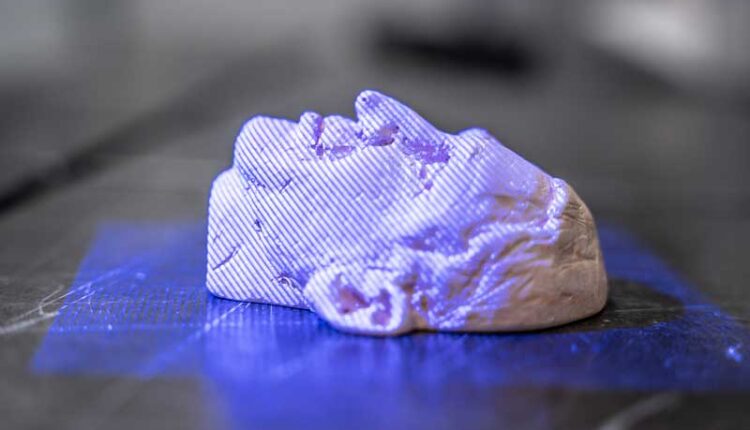

Exact Metrology: A Division of In-Place Machining Company and a comprehensive 3D metrology service provider and hardware sales company, recently used Blue Light Scanning technology to mass-produce celebrity-themed soaps. These soaps will be sold by a non-profit for charity.

Blue Light Scanning, a form of structured light scanning technology, operates by using a combination of the projector, camera, and a lens system. By using a projector, a pattern of light is created and the shadowed, dark areas on the object get measured for data collection. The scanner utilizes optical non-contact technology to capture millions of accurate points in a single fast scan.

Noah Branscum, Exact Metrology Application Engineer for Short Range Scanning, working at the company’s Cincinnati office, completed the soap scan. Steps involved using reference points to help the scanner understand where the carved head is in space.

Then, he took a “scan” using the scanner to display the lines of blue light onto the part and had two cameras reading how the lines refracted off the part, producing multiple lines of 3D points in space.” After going around the part to take several scans, Branscum proceeded to use reference points to stitch each scan together. He then created a .stl file of the 3D scan data by way of a “mesh”, using ATOS Professional software. This software is used to operate the sensor head, process the 3D point cloud data, and edit and post-process the data. Besides polygon mesh generation and editing, additional features include sensor control, sectioning, and primitive generation.

Scanned car part with Blue Light

Discussing the challenges of scanning these famous faces, Branscum commented the scanner was limited in its “line of sight.” “Things like between the eyes and eyelids can be a bit though, or where there are very sharp valleys like the lips.” Thankfully, ATOS Professional also helps fill in the holes with feature and character line detection.

Asked about future projects like this, Branscum concluded, “We love challenges and this was a fun experience for us. We look forward to working on equally challenging projects in the future.”

This content was originally published on the Exact Metrology website.