EOS and Audi expand range of applications for Metal 3D Printing

The development partnership between Audi and EOS has reached a new milestone: Audi has moved entirely to additive manufacturing for selected tool segments for hot forming at its Metal 3D Printing Centre – conventional production methods are no longer used in these cases. The premium manufacturer leverages the EOS M 400 system for 3D printing.

AUDI AG, a leading manufacturer of premium vehicles, is relying entirely on industrial 3D printing at its Metal 3D Printing Centre in Ingolstadt for the production of selected tool segments. Additive manufacturing (AM) with EOS technology is used for 12 segments of four tools for hot forming. Plans call for significantly more segments to be printed this way. Audi uses the tool segments produced using the EOS M 400 system in its press shop to make body panels for models including the Audi A4. The company plans to do the same for future electric vehicles.

Shifting part of its tool segment production activities from conventional manufacturing to AM is an important step, highlighting both the quality and reliability of industrial 3D printing and the design freedom advantages this production method offers.

This is the latest outcome of the longstanding cooperative relationship between Audi and EOS in Ingolstadt. EOS provided support in the form of technology and know-how before and during the construction of Audi’s 3D printing center-back in 2016.

Since then, experts from both companies have been making steady progress on the use of AM, and Audi has established an ideal application in the area of hot forming for series vehicles. Several hundred thousand parts have already been produced using the 3D-printed tools and installed in selected models.

From initial qualification by EOS to internal further development and refinement of the entire process chain through to standardization of a new production method, we are now reaping the fruits of years of development within Audi’s production organization. Whenever conventional manufacturing methods reach their limit, we use additive manufacturing – which lets us meet quality standards and comply with production times.

Matthias Herker, Technical Project Manager at the Audi Metal 3D Printing Center

Advantages of 3D printing for tooling

Markus Glasser, Senior Vice President EMEA at EOS, says: “The latest examples show that 3D printing has become an established part of operating materials production at Audi. We’re especially proud that the tool segments made using AM are created exclusively using an industrial 3D printer from EOS. Audi is a partner we can work with to continue to drive the use of AM in automotive production – a key industry for us.”

Markus Glasser, Senior Vice President EMEA at EOS, says: “The latest examples show that 3D printing has become an established part of operating materials production at Audi. We’re especially proud that the tool segments made using AM are created exclusively using an industrial 3D printer from EOS. Audi is a partner we can work with to continue to drive the use of AM in automotive production – a key industry for us.”

When additive manufacturing is used at the Audi Metal 3D Printing Center, the focus is on hot forming segments and high-pressure die casting tool inserts. The design department in Ingolstadt creates entire tools, which can measure as much as 5 x 3 meters.

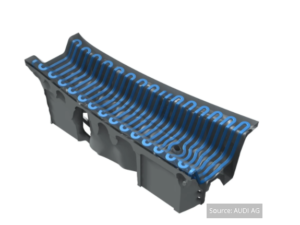

The individual additively manufactured tool segments in turn can be up to 400 mm in length and weigh as much as 120 kg. The size and complexity of the tool segments mean that construction times of up to 20 days are not uncommon, which is why the reliability and quality of the EOS M 400 3D printing system that is used are crucial success factors.

3D printing makes it possible to create highly complex cooling channels configured for the specific component within the tool segments. This provides contoured, more-even cooling, making it possible to shorten cycle times with outstanding quality – a critical point for series production of the actual vehicle component.

This content was originally published on the EOS website.