Drill Bit Re-Sharpener(13D, 26A/D)

Description

The Drill Bit Resharpner (Model – 13D) is between the range of 3MM to 13MM. The machine includes ER 20 Collets and every collet has a different size. This feature gives the user a choice to select the drills as per the size required in the machine. For this, the process starts with the collet been fixed into the holder. After that one needs to set the web diameter according to drill size. The features of the machine include point angle grinding & relief angle grinding. It also includes web thinning and results in a perfect aesthetic drill.

- Portable drill grinder. With the Taiwan Grinding wheel, it can be equipped directly with an accurate angle and long service life.

- 13D/26D can sharpen the drill bit front cutting lip, lip relief angle, you also can control the center spot at random instead of a center drill, escape chips easily, drill with a light heart.

- Standard equipement:13# eleven collets; 26# fourteen collects.

- Standard grinding range: 13# (Ø2.1 -Ø13); 26# (Ø12.1 -Ø26).

- Standard Collect Model No : 13A/D (11 Pes – ER20): 3,4,5,6,7,8,9,10,11,12,13

- Standard Collect Model No.: 26A/D (14 Pes – ER40): 13,14,15,16,17,18,19,20,21,22,23,24,25,26

- Grinding Wheel: CBN Wheel For HSS Drill Bit / SD Wheel for Carbide Drill Bit

- It is not so easy to align the drill-less than 3mm.

Technical Specification

| Model | 13A/D | 26A/D |

|---|---|---|

| Grinding range | Ø2.1-Ø13(Ø15) | (Ø8)Ø13-Ø26(Ø32) |

| Point Angle | 100° (95° )~135° | 95° ~135° |

| Power | AC220V | AC220V |

| Motor | 180W | 250W |

| Speed | 4800RPM | 4800RPM |

| Grinding wheel | CBN(HSS)USD | |

| Dimension | 32x18x19cm | 46x24x22cm |

| Weight | 10kg | 27kg |

Operation Procedure

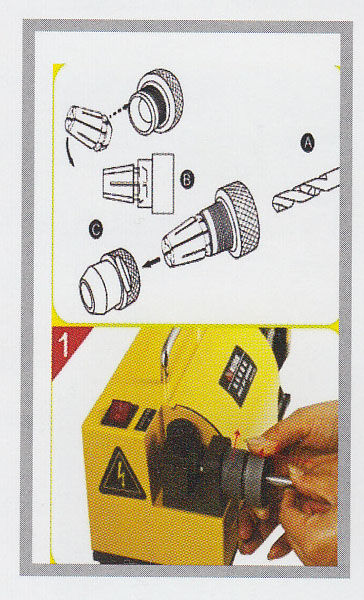

Bits Of The Assembled Group Fixture :

- Make sure the material of the drill and choose a suitable grinding wheel.

- Standard iis CBN grinding wheel.* CBN wheel is suitable for HSS drill, SD wheel is suitable for carbide drill.

- Set left scale annulus to be “0” position. Turn the scale clockwise to the end, then contra rotate to adjust to the “0” position.

- Choose a suitable collet for the collet holder. (Insert the collet into holder in the 45 degree)

- Follow up the steps for setting up the drill to the collet holder, without tightening. Keep the room for adjusting the drill.

- Adjust the left scale to meet the diameter of the drill.

- Insert the collet holder with the drill into the left hole and completely touch, then turn right to set up.

- Insert the top of the drill into the end, turn right to set up.

- Tight the drill by collet holder for setting up the grinding position.

- Take out the chuck

Grind The LIP Relief Angle :

Insert the collet holder with the drill into the sharpening hole (at the top) until the bit point slightly touches the wheel. Then move left and right repeatedly to sharpen the drill until the grinding sound disappeared take it out and turn 180 degrees, do the same.

The machine is set up with the point (central point) size adjustment function, which can effectively coordinate b as ed on the material of drill hole and the rotation a peed. It can control the quality precision and prolong the service of the boring bit. Our target is to let or ding workers become the master of the grinding drill.

Grind The Point Angle :

Turn on the power of the grinder, then insert the collet holder with a drill and push to the grinding wheel slowly. Next, move left and right repeatedly to sharpen the drill until the grinding sound disappeared. Take out the chuck, turn 180degree and repeat the same process. * Don’t hold the drill when you grind, or it will influence the grinding.

*Point angle can be adjustable from 90 degree to 180

Grind The Front Cutting Up :

Insert the collet holder with the drill into the hole (at the top) until the bit point slightly touches the wheel. Then turn the chuck clockwise until the grinding sound disappears. Take it out and turn 180degrees. Do the same.

This content was originally published on the Bhavya Machine Tools website.