DMG Mori: Automated single part and small batch production

As a full-service provider in toolmaking, Top Grade Molds, Ltd., founded in 1964, provides its customers with competent support from the development to the final sampling of the tools. Injection molds for rigid plastic packaging, for example, in the food industry, is the core business.

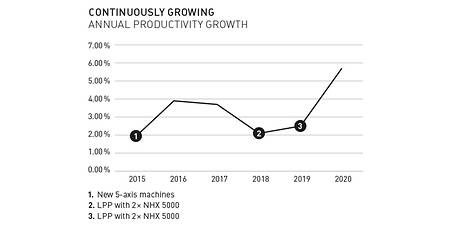

The Canadian company from Mississauga, Ontario (near Toronto), employs 150 well-trained specialists to meet the high-quality standards of the industry. Top Grade Molds meets the precision requirements with modern machine tools from DMG MORI. Since 2011, the company has already installed 13 models from the machine tool manufacturer, including several duoBLOCK machines and one NHX 10000, as well as four NHX 5000, which operate highly automated with the help of two linear pallet pools (LPP) – thus increasing the productivity of Top Grade Molds literally overnight.

“As a manufacturing service provider in tool and mold making, we consistently machine single parts and small batches,” Vince Ciccone, President, and CEO of Top Grade Molds, explains the day-to-day production process. Co-operation with customers often begins in the product development phase. In order to remain competitive, he says, it is necessary to react flexibly and design efficient production. “Turning and milling have by far the largest share with 80 percent. In DMG MORI, we have found a real partner in this field.” The cooperation with customers often begins in the product development phase.

Uniform control and production technology from DMG MORI

There were two main reasons why Top Grade Molds started investing in machine tools from DMG MORI in 2011. On the one hand, the wide product range offers suitable manufacturing solutions for almost every application; Vince Ciccone says: “On the other hand, we wanted to establish a consistent control system.” Independent of the underlying control system, CELOS offers a uniform and clear interface. “This makes training on new machines much easier.” The processing variety of the DMG MORI models is also an important factor: “We always have new orders and often set up the machines anew. Large tool magazines and good accessibility also give us the necessary flexibility.”

NHX and duoBLOCK – process reliability in tool and mold making

Vince Ciccone sees the key to optimum production in producing the demanding high-precision components for injection molds with the required precision and, above all, productively: “The rigidity and high repeat accuracy of the DMG MORI machines are the perfect basis for this.” This is why the stable duoBLOCK machining centers and NHX models were chosen in the past. In 2019, one NHX 10000 and two NHX 5000 – in addition to the two existing NHX 5000 – were purchased. The inherently rigid machine bed, the stepped moving column in the x-axis, and 70 mm spindle bearing diameters give the horizontal machining centers the rigidity required for precise machining. A direct path measuring system with 0.01 µm resolution is also included.

Automated through the night

With a table load of 700 kg and traverse paths of 730 x 730 x 880 mm, the NHX 5000 covers a wide range of parts so that Top Grade Molds can respond well to the constantly changing orders. In this case, production was to be automated, as Vince Ciccone recalls: “Of course, the aim was to increase capacity with automation.” Two of the NHX 5000 are combined with a linear pallet pool. “But equally important was the flexibility to produce both individual parts and small batches automatically.” The LPP installed by DMG MORI has 20 pallets, each measuring 500 x 500 mm, and a set-up station. The tool management is also integrated into the two automation solutions so that a total of 120 tools are available per LPP. “This allows us to keep the machines working all night without any problems.”

NHX 10000: Horizontal machining up to 5,000 kg workpiece weight

Top Grade Molds has expanded its large part machining capacity with the NHX 10000. Traverse paths of 1,700 x 1,400 x 1,510 mm and a table load of up to 5,000 kg. The XXL horizontal machining center is made for high-performance machining. The spindle has a maximum power of 40 kW and 1,413 Nm torque. The drive in the center of gravity and the box-in-box design allow for vibration-free and precise machining.

Vince Ciccone appreciates the long-standing cooperation with DMG MORI because the machine tool manufacturer now knows the requirements of Top Grade Molds: “They can anticipate very precisely, which manufacturing solution will move us forward. We are in a growth phase and are constantly looking for innovative solutions to optimize our processes and open up new markets.”

This content was originally published on the DMG Mori website.