Divide By Zero: Automotive seat manufacturer saves 50% of prototyping time and cost with 3D Printing

When it comes to automotive seats, the very first thing that comes to our mind is comfort; every automotive manufacturer gives utmost attention to the design of seating systems and ergonomics of the vehicle interior.

At Divide by zero technologies, we are India’s largest industrial 3D printer Manufacturers and solution provider; we work with our end customers to solve issues with prototyping, tooling, and mass-customized parts.

Our Client:

We worked with Harita Seatings – A leading automotive seating solution provider in India and a TVS group company.

With multiple manufacturing plants across the country, our client – Harita seatings is a leading organization in designing, building, and manufacturing innovative and customized seating systems for automobiles.

The Problem :

The client was in need of manufacturing functional prototypes of the seating solutions that they design in accordance with customer needs and requirements. These prototypes help them to deliver a complete feel of the solution along with cost estimation.

These prototypes were manufactured either in FRP (Fiber Reinforced Plastic) or thermoformed parts. In either of the cases, they had to make the mold/pattern and the timeline for making the same was close to a minimum of one week.

Due to its sheer designated size and the design complexity, they used to build prototype samples in small segments and later glued them together to build the complete finished product. Consequently, the final product wasn’t ready for functional testing thereby giving only aesthetic sense.

Moreover, due to longer build time and high-cost investment, the design team faced serious challenges in getting client approval on the proposed design.

Solution :

Divide By Zero’s applications & solutions team suggested material and process parameters print seat components for functional testing and also supplied initial samples of the 3D printed prototypes which matched the required specifications to withstand the strength and high pressure.

- The client and its customers were happy with the initial quality tests and analysis of the prototypes.

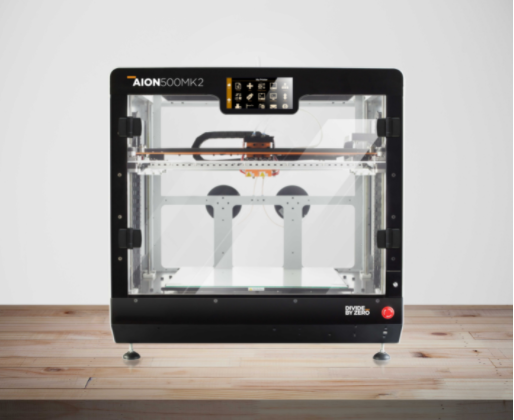

- Unlike the traditional methods, AION500 MK2 is an industrial large-scale 3D printer that is used to build large-sized parts in one go with deposition rates up to 50 cu/cm for precision parts.

- The client was satisfied with the overall assembly, functionalities, aspects, and aesthetics of the prototype.

- With the design cycle reducing to just 35 hours which was initially executed at 7-8 days using traditional methods, the engineering challenges previously faced by our client were taken care of.

| Process | Development Time | Development Cost |

| Traditional Manufacturing | 8 Days | INR 5600 |

| 3D Printing | 2 Days | INR 1800 |

| Saving | 75% | 68% |

AION 500 MK2 is an India Design Mark’s award-winning, high-speed, IoT-enabled, massive-size 3D printer that offers a large build volume at an affordable price point. Armed with our patented FM (Advanced Fusion Plastic Modeling) technology, the printer renders a stronger and durable output. With multiple connectivity options and sensors, it is one of the most advanced 3D printers available. Offering a large build size, ultra-fast print speeds, minimal post-processing, and unmatched precision, the AION500 MK2 is designed for versatility.

Client Feedback

“The performance of the machine is found Good, Quality of 3D printing meets the expectation. Features of the machine is at par with international standards.

We have been using this machine since last one year for prototyping and it helped us to reduce the development lead time and the cost as well, when comparing with service providers.

Overall performance of the machine and service support from DB technologies quite satisfactory.”

– K.Selvam

Head Central Production Engineering

Crux

3D printing technology has drastically changed the way products are envisioned, designed, and prototyped for over a decade now. Many industry verticals have already integrated 3D printing technology while phasing out archaic and inefficient prototyping methodologies. Divide By Zero Technologies aims at addressing acute and challenging industrial problems whilst maintaining quality assurance keeping investment incurred under budget. We believe in inclusive innovation which is why we keep our doors open for collaboration and partnership, and just not business profitability. India is gradually emerging as a global superpower and to address arising problems we, at Divide By Zero, work tirelessly towards building a better India. However small our efforts are, all we do is accountable for the development of skilled and technologically advanced India. With patented AFPM technology as one of our Unique Selling Proposition, the client could develop and execute new designs and build prototypes using 3D printing at minimum time consumption and overall cost incurred.

This content was originally published on the Divide By Zero website.