Die and Mold recovery driven by the automotive industry: Mazak USA

High accuracy 5-axis machining centers for differentiation in today’s global competition

The market size of the worldwide Die and Mold industry in 2016 was 8,500 billion yen (approx. 85 billion $) with the top 3 countries in terms of production – China, the United States, and Japan. The Die and Mold industry in Japan, which was in recession immediately after the Lehman Brothers bankruptcy in 2008, has continued to recover driven mainly by the automotive industry after 2010. On the other hand, the Japan Die and Mold industry association joined ISTMA (International Special Tooling and Machining Association) again. By doing so, further growth and development are expected by collecting and sharing information from the Die and Mold industries and manufacturers all over the world.

Yamazaki Mazak has developed UD-400/5X, a high-accuracy 5-axis machining center. This machine features the latest material technology, performance specifications, and machining technology. High productivity and process integration (Done-in-One) can be efficiently realized by this machine and will be introduced to customers. The new Hybrid 5-axis multi-tasking machine series has been developed by Mazak with a unique concept. With machines such as the INTEGREX AM and the VARIAXIS j-600/5X AM dies and molds can be machined completely, including cladding and finish machining. These machines make it possible for Yamazaki Mazak to realize exceptional process integration.

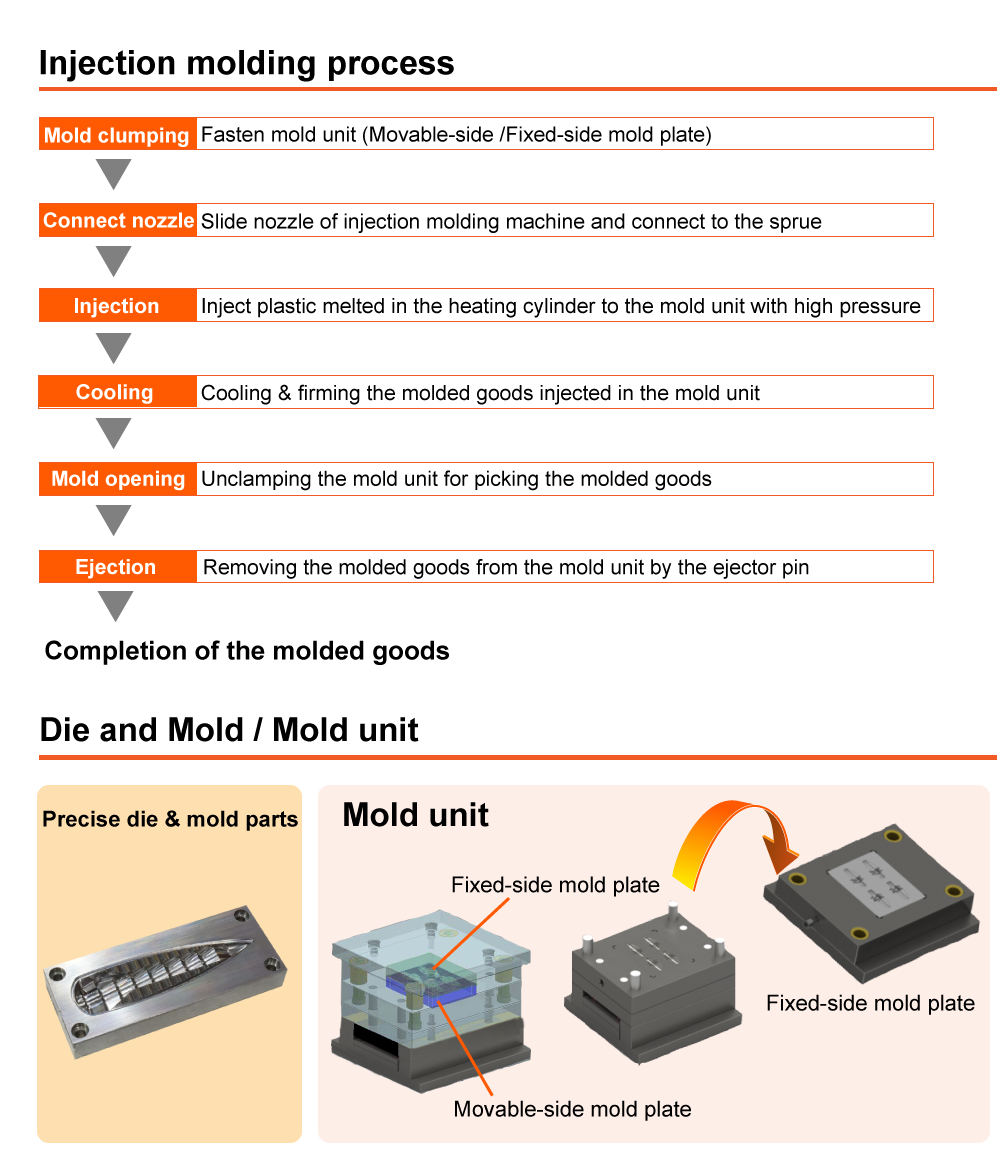

Construction Of Injection Molding Machine And Plastic Molding Process

This content was originally published on the Mazak USA website.