Dassault Systemes: PASOTTI DESIGNWORKS-Small toys, but big ideas

Milan-based design studio Pasotti Designworks was founded in 2010 by Alessandro Pasotti, a toy designer with experience in developing products for a range of different sectors including complex technical goods, furniture, and sporting equipment.

“I have a unique skill set,” Pasotti said. “I have a creative background, but I also have mechanical and technical knowledge. This has given me a particular attention to detail when it comes to the different types of processes involved in creating small injection molded plastic toys for children aged 3-6 years old.”

Pasotti firmly believes that creativity is in his blood. “My father was a master designer using injection molding, so I was heavily influenced by this,” he said. “I grew up with many of his projects all around my home – these are wonderful memories.”

In fact, Pasotti’s father was an early adopter of bi-dimensional CAD technology. “I remember him teaching me how to use it,” Pasotti explains. “And I was just eight years old when I designed my first simple drawings using CAD in the late 1980s.”

Pasotti’s passion for design was solidified during that time. “My early years definitely influenced my path to become a designer,” he said. “Today toys are my passion. I love being able to create products that encourage kids’ creativity and role play.”

Pasotti’s designs are accurate interpretations of real products: kitchens, trolleys, scooters and so on. They often are incredibly intricate, sometimes in 1:1 proportion but also scaled down so that they can be carried around in a small hand and played with on a table.

I’m a single user of this technology, so if I can do it, anyone can.

But Pasotti’s success has brought about challenges. “Today I serve both big global companies and small local ones,” he said. “But there are far more demands on me than there ever were in the past. Sustainability and safety are two big issues.”

From a sustainability perspective, Pasotti faces the need to use less plastic, reduce the weight and overall volume of the toys so that less materials are used, and optimize designs to reduce waste and ensure the best materials are chosen for production. “My clients need more in terms of safety too,” Pasotti explains. “The regulatory burden is huge, and has an impact on the ergonomics of a product.”

Playability is also important. “A good toy is a safe toy, but it must also have excellent playability,” he said. “This means it should have multiple functions, it must be fun and, if it is a character, it must have a personality. You may think it’s funny, but I think it’s important to play with similar toys before I start designing a new one – it sparks my imagination and helps me create the best designs.”

In addition to the design challenges, Pasotti must also deal with many client changes. “A product usually goes through a large number of iterations before the final design is approved,” he said. “The modifications and updates involved are always very complex.”

Meeting these demands was becoming increasingly difficult.

“In order to satisfy all of the requirements, I had to use many different software solutions, and often had integration issues when exporting and importing designs – something I had to do over and over when working on new product iterations,” Pasotti said. “Tracking changes was incredibly challenging in this kind of siloed environment – I regularly struggled with discontinuous workflows and data losses. I realized the process was far too time consuming and incredibly inefficient.”

Pasotti sought a unified solution that would give him access to all the tools he needed, all within the same platform. “I needed a better methodology to think, design and engineer a product,” he said. “It needed to be tuned to grant the perfect mix between the creative side and the engineering side of the product itself.”

The search for a unified platform

Pasotti was already familiar with Dassault Systèmes’ CATIA V5 software. “That’s why the 3DEXPERIENCE® platform was a natural choice,” he said. “I did consider alternative software, but there was nothing that offered the same level of integration. The ability to control your workflow, and to have full control over changes, really appealed to me.”

The implementation process proved straightforward. With help from Dassault Systèmes’ local business partner Design Systems, the 3DEXPERIENCE platform was installed on premises. “Because of my existing knowledge of CATIA, along with the 3DEXPERIENCE platform’s intuitive and friendly user interface, I learned how to use the tools very quickly,” said Pasotti. “I find the platform incredibly immersive and engaging. In fact, it is a joy to use – a real visual experience.”

Pasotti also got comprehensive support in using the tools he wasn’t so familiar with. “The one area that I found a bit challenging was learning how to manage the lifecycle of my products, and their related data, with ENOVIA. Design Systems really helped me with this. I undertook some training courses and felt well supported.”

Pasotti soon became well versed in the technology, and began to realize the full potential of the platform.

Better model control is very important as I can duplicate and modify designs without starting from scratch. This, along with my ability to make better, faster decisions, has resulted in efficiency gains of around 20%.

Alessandro Pasotti

Designer & Founder, Pasotti Designworks

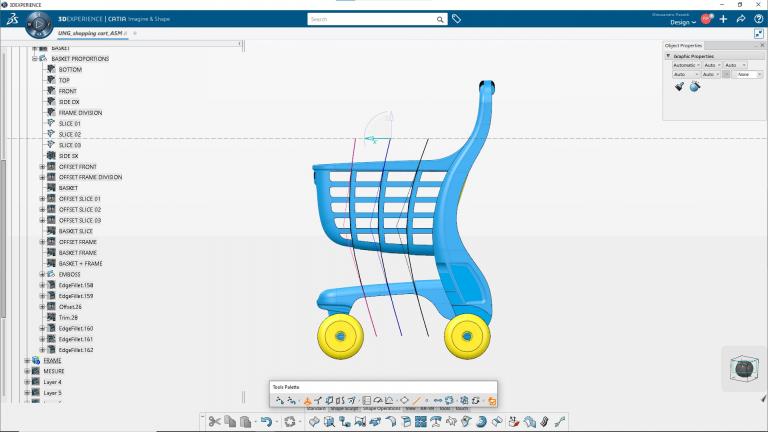

“One of the first toys I designed using the 3DEXPERIENCE platform was a real-size shopping cart,” he said. “I used many different apps within the 3DEXPERIENCE platform to achieve the final result.”

Pasotti used the Imagine & Shape app to create the three separate parts that made up the final design – the frame, the basket and the base with wheels. “I then put these parts together using the Generative Shape Design app, and proved whether my designs will work or not using Assembly Design,” he said. “I was then able to engineer the model using the Advanced Part Design app, and evaluate the final results using Live Rendering. Finally, I used the Kinematics tool to check the movement and control the weight of the product.”

Overall Pasotti was blown away by what the solution could do. “With the 3DEXPERIENCE platform, everything has changed,” he said. “I’ve defined a multi-directional workflow, which has enabled me to work using my own methods – I can manage my specification tree the way that I want and make real improvements to the way I operate. Because all of the apps are in the same platform, I don’t have to constantly import and export documents – and that’s been a real gamechanger.”

Now, when Pasotti makes a change to a base shape or early design, those adjustments are automatically made to the entire model and to all subsequent drawings. “Even if I’ve got to the engineering stage and have to go back and make a change to the overlying shape, those changes are automatically reflected in the assembly design,” he said. “In the past I would have had to reconsider parts of the design process from the beginning.” It’s this ability to combine the creative side of design with engineering that Pasotti really appreciates. “The 3DEXPERIENCE platform supports every aspect of every design stage – from the initial sketches to the finite geometry for production. I try to use all of the apps because they are all incredibly powerful and useful. When I use the solution, I really feel part of a digital environment – part of a community in fact.”

Reduce, reuse and recycle

Using the platform, Pasotti has been able to better meet strict sustainability and safety requirements. “I have full control over everything,” he said. “I can define the correct distance between the paths of two moving parts, for example, and make adjustments accordingly. I can instantly see the weight of a product and play around with it as well. I can also evaluate the ergonomics in order to ensure safety.”

Pasotti also enjoys the new level of efficiency he has gained by using the platform. “I save time because I am able to make changes and revisions without destroying the geometries of the product,” he said. “This reduces data loss and massively reduces the chance of errors – which is obviously a benefit for me, but also for my customers too.”

Furthermore, with better model control, Pasotti can now create new variants of products by reusing key components. “This is very important as I can duplicate and modify designs without starting from scratch,” he said. “This, along with my ability to make better, faster decisions, has resulted in efficiency gains of around 20%. This is remarkable.”

Customers are happier too. “The companies I work with have become aware that I can work faster, and produce higher quality designs,” he said. “I share every single step with them through the platform – I can share the screen so that they can see the changes I make and approve new variants quickly. They really appreciate this greater visibility. They also enjoy the fact that, no matter how many revisions I have to make, they always receive a high quality file.”

Overall, Pasotti believes his new way of working has set him up for greater success going forwards. “The 3DEXPERIENCE platform, for me, allows real innovation. It’s my go-to business tool to achieve excellent results,” he said. “Having a methodology in place to support my everyday work is incredibly beneficial. I’ve improved my workflow by using a unique integrated solution that covers the entire design process, from concept to production.”

As a result, Pasotti would not hesitate to recommend the 3DEXPERIENCE platform to others. “It’s common in big design studios to see designers create something using a specific tool and then condense it and move it to another piece of software,” he said “But that’s not an efficient way of working. It’s very powerful if you can begin the process in the right way – inside a unique integrated platform.”

Pasotti says that this type of approach is not only reserved for big companies, but is useful for small ones like his too. “It really exemplifies the concept of lean management,” he said. “I’m a single user of this technology, so if I can do it, anyone can.”

With the 3DEXPERIENCE platform, everything has changed. I’ve defined a multi-directional workflow, which has enabled me to work in my own unique way. Because all of the apps are in the same place, I don’t have to constantly import and export documents – and that’s been a real gamechanger.

Alessandro Pasotti

Designer & Founder, Pasotti Designworks

Future perfect

Looking ahead, Pasotti believes the 3DEXPERIENCE platform will help him improve his business further. “I want to build on what I’ve already learned using ENOVIA and improve my project management knowledge,” he said. “Using the dashboard I hope to control my entire design flow. I can see the potential to do far more when it comes to managing concurrent projects.”

Pasotti hopes to achieve this in the next few months, before embarking on his longer-term vision. “I may run a small business, but I think big,” he said. “My strategy is simple: to create, consolidate and then develop again.

“I don’t want to be a simple supplier,” he added. “I want to be the go-to partner for companies across the world. I want to build long-lasting relationships. With the tools I have in the 3DEXPERIENCE platform, I have no doubt I can get there.”

This content was published first on the Dassault Systemes website.