Common Types of Sheet Metal

There are many different metals and alloys that come in sheet form and are ultimately used in the fabrication of manufactured parts. The choice of which material depends largely on the final application of the fabricated parts, things to consider include formability, weldability, corrosion resistance, strength, weight, and cost. Most common materials found in precision sheet metal fabrication include:

Stainless Steel

There are a number of grades to choose from, for the purpose of this white paper we will focus on the top three found in precision sheet metal fabrication:

- Austenitic stainless is a non-magnetic – any of the 300 series steel – that contains high levels of chromium and nickel and low levels of carbon. Known for their formability and resistance to corrosion, these are the most widely used grade of stainless steel.

- Ferritic – Stainless steels that are magnetic, non-heat-treatable steels that contain 11-30% chromium but with little or no nickel. Typically employed for non-structural uses where either good corrosion resistance is needed such as with seawater applications or decorative applications where aesthetics are the main concern. These metals are most commonly found in the 400 series stainless steel.

- Martensitic – A group of chromium steels ordinarily containing no nickel developed to provide steel grades that are both corrosion resistant and hardenable via heat-treating to a wide range of hardness and strength levels.

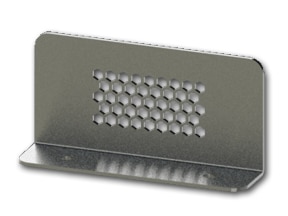

Cold Rolled Steel

A process in which hot-rolled steel is further processed to smooth the finish and hold tighter tolerances when forming. CRS comes in 1008 and 1018 alloys.

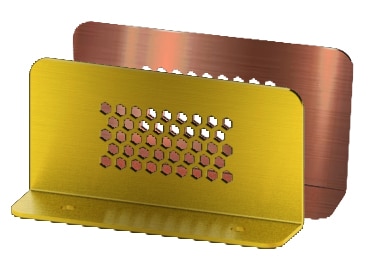

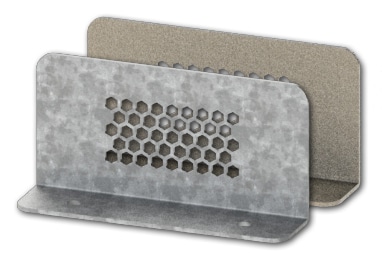

Pre-Plated Steel

Sheet metal material that is either hot-dipped galvanized steel or galvanized steel, which is galvanized then annealed.

Galvanization is the process of applying a protective zinc coating to steel in order to prevent rust and corrosion. Annealing is a heat treatment process that alters the microstructure of a material to change its mechanical or electrical properties, typically reducing the hardness and increasing the ductility for easier fabrication.

Aluminum

Outstanding strength to weight ratio and natural corrosion resistance, aluminum sheet metal is a popular choice in manufacturing sectors meeting many application requirements. Grade 1100 offers excellent corrosion resistance, excellent workability, as well as high thermal and electrical conductivity. Often found in transmission or power grid lines. Grade 3003 is a popular alloy for general purposes because of its moderate strength and good

workability. Used in heat exchanges and cooking utensils. Grade 5052 and 6061 are commonly found in metal fabrication. Grade 5052 is the most widely used alloy best known for being among the stronger alloys while still formable, weldable, and corrosion-resistant. Grade 6061 is a solid structural alloy most commonly used in extrusions or high-strength parts such as truck and marine frames.

Copper/Brass![Copper and Brass Metal Samples]()

With lower zinc content brasses can be easily cold worked, welded, and brazed. A high copper content allows the metal to form a protective oxide layer (patina) on its surface that protects it from further corrosion. This patina creates an often highly desirable aesthetic look found in architectural or other consumer-facing products.

This content was originally published on the Metafab website.