Clear the way for automation: KUKA brings the first intelligent bin picking onto the market

Bin picking thanks to the bin picking application

Reaching into a container and pulling out a screw, for example, without banging your arm on the edge is not a challenge for a human. It’s different for a robot. The movement must be precisely planned so that it can reach into the box at the right angle and grab the right part there. Then he can relieve people of boring, monotonous work with bin picking – reliably, quickly and without tiring. For the precise calculation of the robot movement and the angle during picking, KUKA has developed a technology package together with the vision experts Roboception, which can be integrated into the production process with little programming effort.

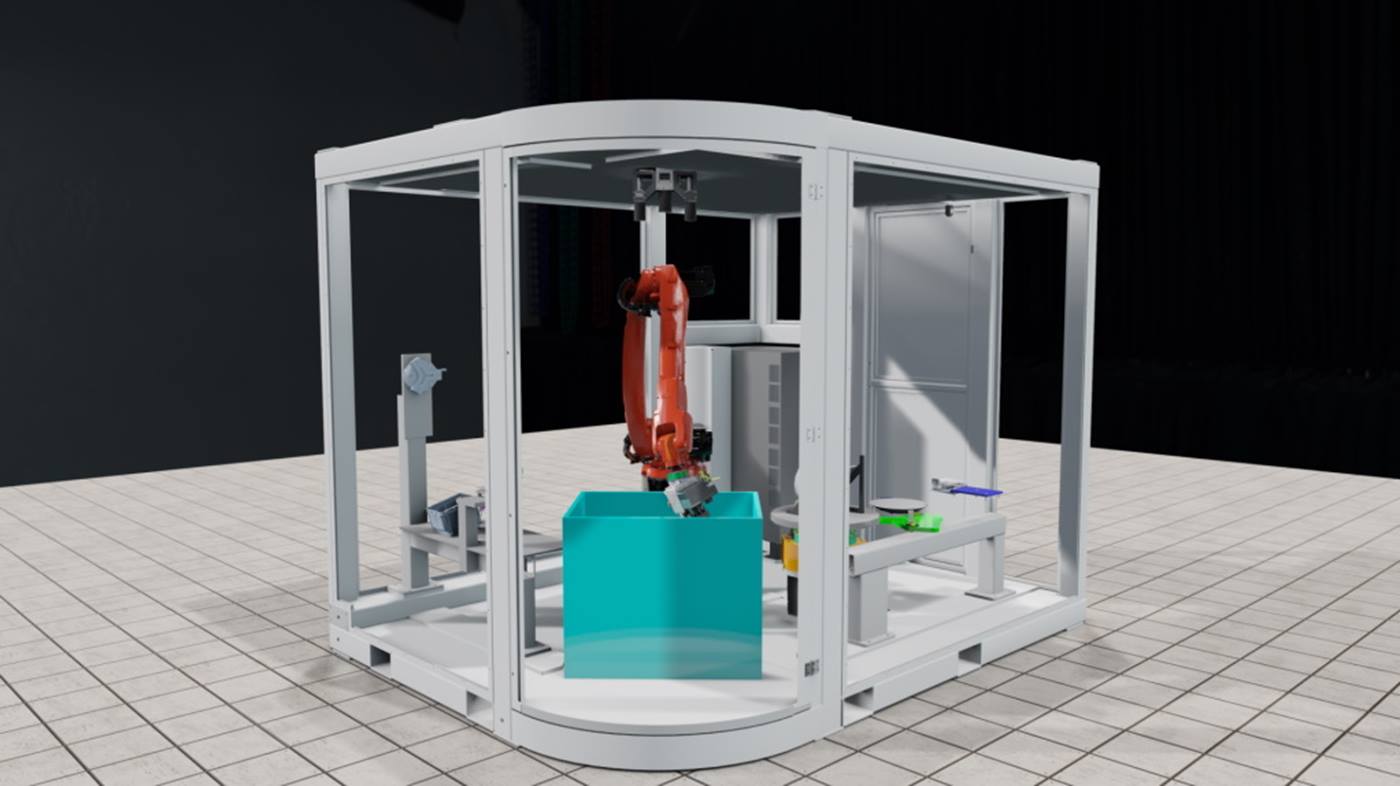

Picking made easy: With the bin-picking cell and the right software, picking different bins is no problem.

Sophisticated path planning for collision-free bin picking

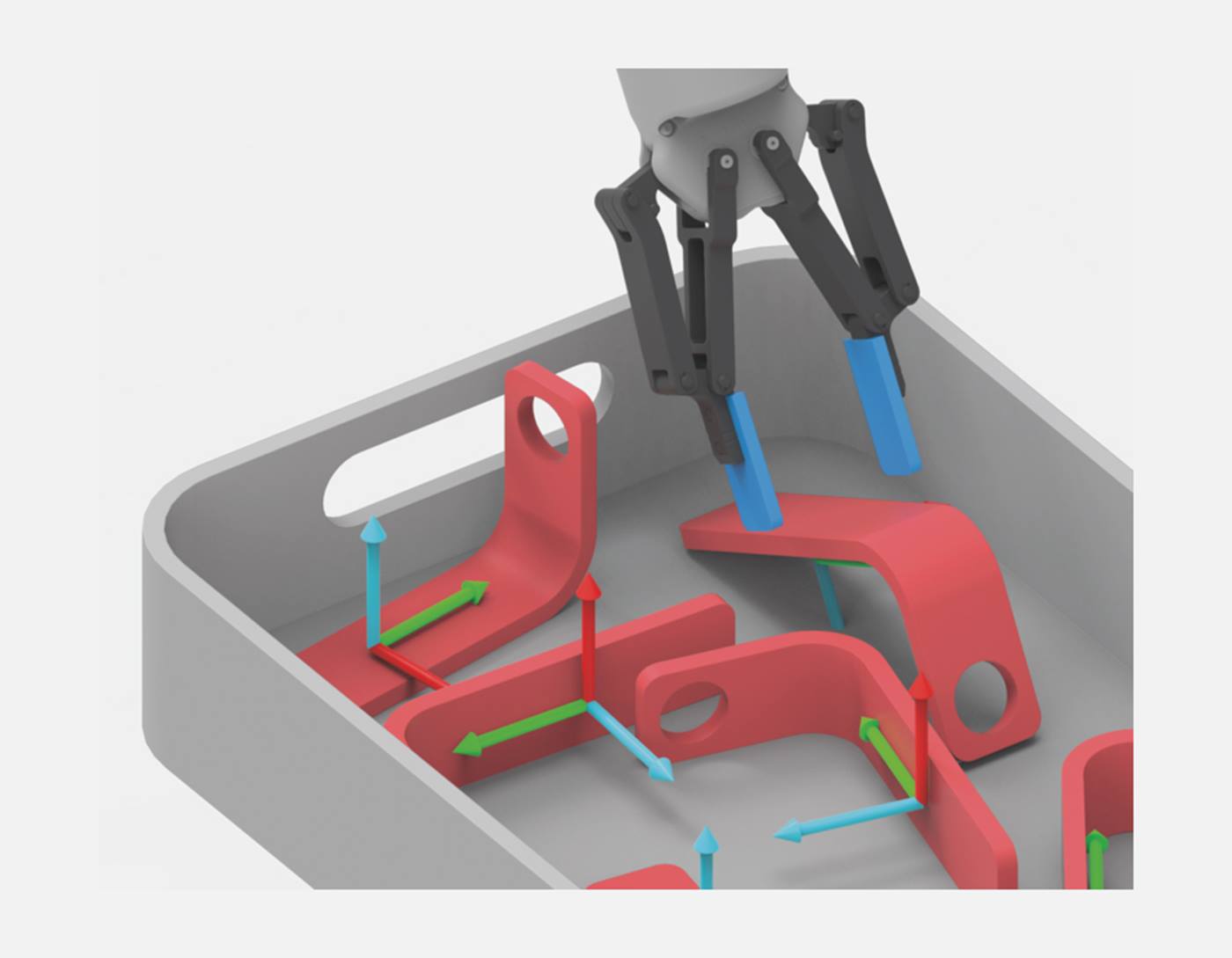

The Roboception 3D camera included in the technology package sends images of the environment and the objects to be extracted to a computer for perfect singularity-free path planning. There, the exact path for the robot arm to the desired object is calculated, including the data of the robot structure and the gripper. The KUKA.SmartBinPicking software calculates the most efficient way to pick components from the bin without the robot arm bumping into them. This collision-free path planning reduces downtimes to a minimum. When recognizing the objects – whether disordered or not – the software also prioritizes which parts the robot will pick up first. For example, because they are on top.

This is how you can reach into every container: Automation through 3D machine vision.

AI-based learning process for CAD model optimization

Object recognition is trained in advance in a photorealistic simulation environment. The CAD model is optimized with regard to color reactions, materials and lighting conditions. “ Each object to be picked from a box is trained in advance in this artificial intelligence-enabled simulation environment over a period of time . This training process can run overnight so that the application can be used the very next day,” says Michael Hohenäcker, portfolio manager for handling and vision at KUKA. The use of AI optimizes the detection of any object so that it can be identified even in difficult scenarios.

With KUKA.SmartBinPicking, the customer receives a technology package with which they can easily and efficiently control bin picking.

Michael Hohenäcker, portfolio manager for handling and vision at KUKA

Highly precise bin picking for any object: The robot can quickly identify the workpiece using a sensor.

Intelligent bin picking for even more automation

In addition, by working with Roboception, KUKA has succeeded in outsourcing the path planning to an external computer and thus not using the performance of the robot controller. This has a very specific advantage: ” While the robot is reaching into the box, the next path planning is being calculated at the same time, ” explains Hohenäcker. That saves cycle times. Customers also save time when integrating the solution. Thanks to modern web technology for the configuration, the customer can view his exact case in a 3D model and easily control the specifications in the system. All you need is basic robot knowledge, but no in-depth programming experience.

This content was first published on the KUKA website.