More than a decade into the Industry 4.0 revolution, you’ve probably heard a lot about the digital twin concept and how this digital replica of a physical asset, system, process, or place offers deeper insights that lead to stronger decision making, optimization, remote monitoring, and confident predictions. You may have even heard that constructing, implementing, and maintaining a digital twin strategy can be risky, challenging, and expensive— but the truth is, to get started with a digital twin strategy, you just need a reliable method of collecting accurate data. A blue light 3D scanner is your simple solution to fast, accurate data collection for easy entry into digital twin strategies.

How Does 3D Scanning Create Digital Twins?

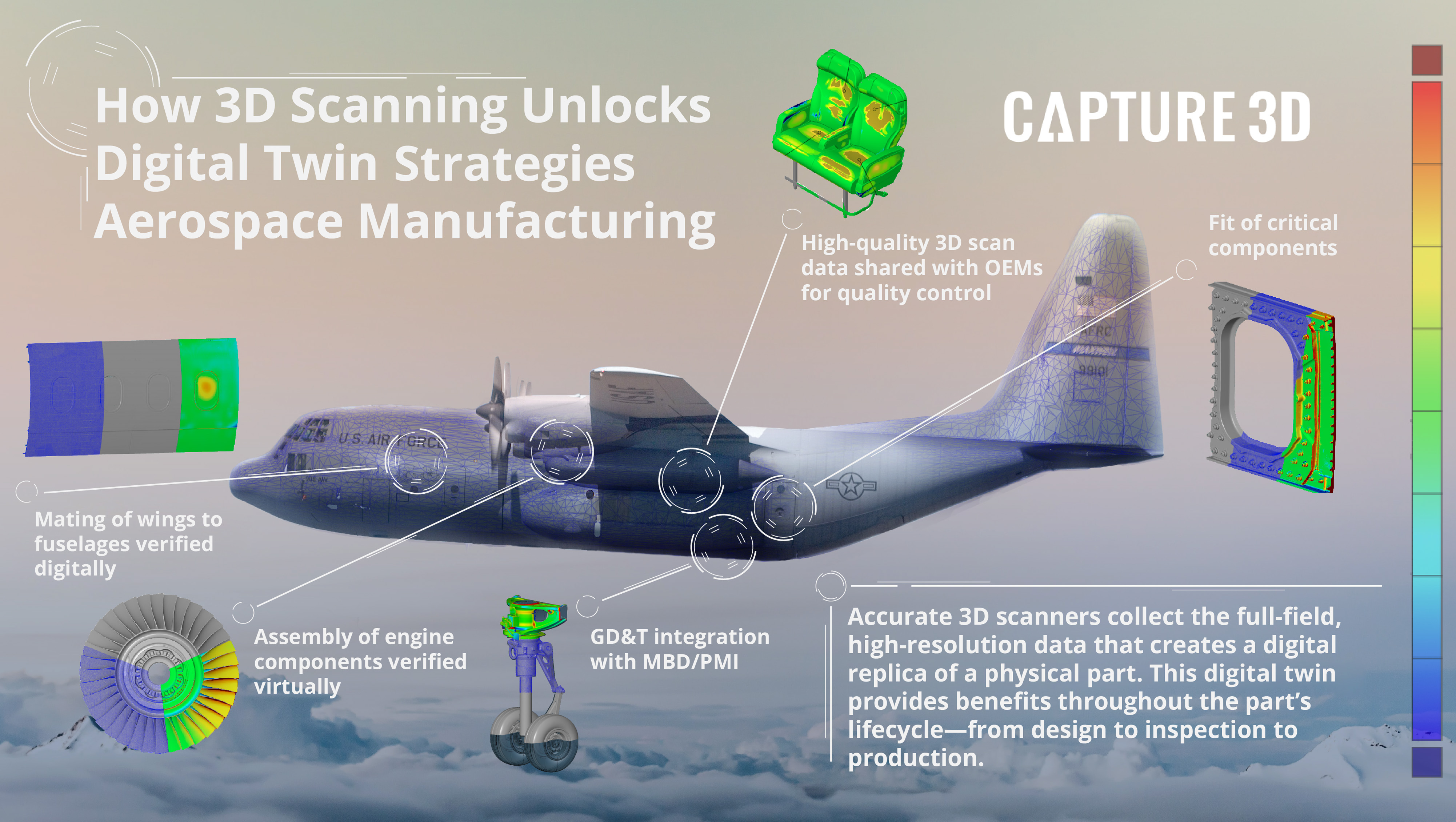

3D scanning technology creates digital twins by collecting millions of data points from the surface of a physical object. The resulting measurement data brings the physical object to life in the form of a fully digitized model, or digital twin, existing in the 3D digital space. However, since data is what powers digital twins to provide you with the ability to monitor, update, predict, and remotely diagnose problems, data quality is crucial. By collecting the accurate, high-quality, full-field data necessary to achieve the high-fidelity geometric identity of a digital twin definition, non-contact, metrology-grade 3D scanners make creating accurate digital twins possible.

While other systems can also collect data, most contact systems aren’t suited for digital twin creation because they rely on tracing specific shapes of the part or use multiple programmed touchpoints to gather data. These methods are time-consuming and don’t yield enough data to create a physical part’s complete geometric identity in a digitized form. Blue light 3D scanning, a non-contact technology, quickly digitizes physical components to deliver accurate digital twins in minutes. The easiest way to begin accessing the power of digital twin technology is to acquire the best 3D scanner for your application.

How to Choose the Best 3D Scanner to Create Digital Twins?

When selecting a 3D scanner to create a digital twin, it’s important to consider factors like part tolerances, part finish, part size, the number of parts, and acquisition time. Parts with tighter tolerances require scanners with higher resolution, while parts with high throughput require automated scanning solutions. When selecting a sensor, you must also consider data density. There must be enough data points on the smallest feature of a part to fully and accurately understand its form.

In addition, it’s worth investing in a high-accuracy 3D scanner to maximize organization-wide benefits gained from a digital twin. Precision data is key to creating a reliable digital replica of components produced because its data gets passed back and forth across the digital thread and carries throughout the product’s lifecycle. For example, manufacturers catalog the digital twins to the serial number of each component produced, achieving vital traceability that helps to eliminate repetition later. The ease of passing precise, full-field data to others through an accurate digital twin creates a connected virtual ecosystem for increased reliability, enhanced performance, and increased agility within the organization. Full-field measurement results on a digital twin enable inter-disciplinary teams to communicate unambiguously. Data visualization clearly indicates where and how the product is failing instead of tabulated measurement results that require extensive analysis to assess error. Leveraging the digital thread to obtain up-to-date information consistently provides companies with real-time data to make immediate decisions within a collaborative environment, leading to profitable growth— but the data must be high-resolution from an accurate 3D scanner for it to be impactful.

How to use ATOS to Create Digital Twins

ATOS 3D scanners offer a gateway into digital twin strategies because they quickly collect millions of data points in each scan, capturing the complete form of a part in minutes. A digital twin comprised of accurate 3D measurement data from an ATOS provides intel about the physical component’s health, trends, and composition, ultimately offering deeper and more valuable insights in a method more efficient than manually interacting with physical systems. These digital twins improve quality control, planning efficiency, and processes through simulation, granting the ability to make reliable decisions based on accurate data— and accurate data is at the core of every good decision.

This content was originally published on the Capture 3D website.