Bechem India: Avoid bearing failure while restarting machines after prolonged stoppage

Machine Restart Guideline for Bearing

Restarting machines without priming after prolonged stoppage can have an adverse effect on the components and land you in further downtime. While there is a vast range of bearings suited for every application based on speed, load, and alignment, optimal lubrication is a common yet critical requirement for efficient performance. Here is a list of possible scenarios that can adversely affect bearing performance due to lubricant starvation and remedies to ideally prep the machine before restart.

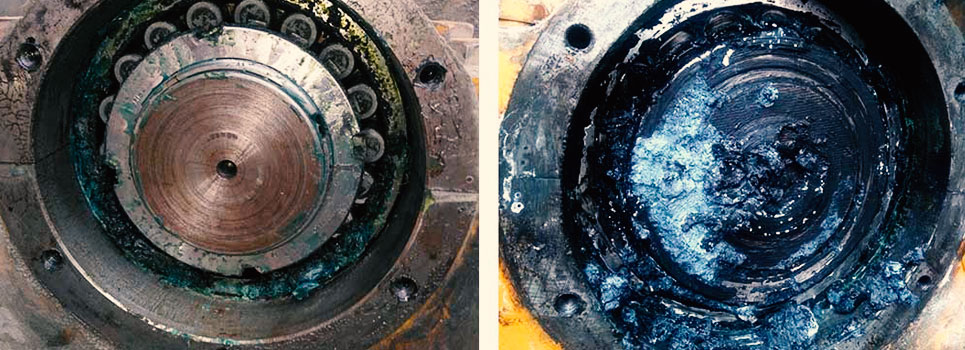

Bearing Exposed To Water

Possible effects due to prolonged stoppage

- Absorption of water in the grease

- The reaction of water with grease creating change inconsistency

- Oxidation of grease

- Additives in the grease (For example, Corrosion protection additives) getting consumed due to prolonged idle time

- Grease film rupture in the load zone of the bearings during prolonged idle time

Restarting after prolonged stoppage

- Clear traces of water and corrosion are present in the housing and grease nipples. Scales and chemical deposits to be removed

- Check the condition of grease nipple for chocking/ corrosion on nipple spring etc. If found faulty replace the nipple with a new one

- Flush bearings free of the old grease by pumping grease through the nipple. Grease pumping to be done until such time the fresh grease comes out

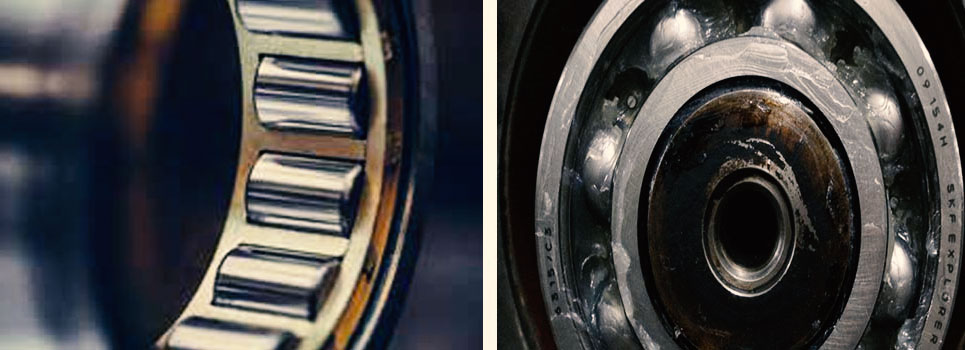

Bearing Operating At High Temperature

Possible effects due to prolonged stoppage

-

Grease oxidation due to exposure to a temperature of around 180ºC

- Grease film break down from the load zone due to static load

- Corrosion on bearings

- Base oil evaporation and grease hardening due to exposure to high temperature

- Reduction in base oil viscosity due to high-temperature exposure resulting in grease bleeding

- Grease hardening due to thermal stress

- Hard residue formation of the grease on bearing which may prevent fresh grease from reaching contact zone

Restarting after prolonged stoppage

- Check the condition of existing grease in the bearing. Physically feel the grease in comparison with fresh grease for oil content.

- If the oil content is 50 % lower than fresh grease, flush the bearing with fresh grease until such time old grease is completely purged out

- If excess grease bleeding/ run down from the housing is noticed, follow flushing procedure as mentioned in the above point

- While applying fresh grease, if resistance is encountered in the grease pump, open the housing and manually clean the old grease residues

Motor Bearing

Possible effects due to prolonged stoppage

- Oxidation of grease due to the presence of catalysts like bearing steel, housing, end cover, etc.

- Reduction in base oil properties due to oxidation and shear.

- Cake formation of grease in the bearing. External contamination like dust, process residue, etc.

- Chocking of grease nipples and hardening of grease in tubes used for applying fresh grease.

Restarting after prolonged stoppage

- Since the relubrication quantity recommended for motor bearings is only a few grams, it is recommended to re-grease all motors before restarting. Care to be taken to apply only the recommended grease quantity

- Check for grease hardening in the grease nipple, pathway, and exit port. Remove hardened grease before relubrication

- Check for grease hardening in the tubes used for relubrication. Flush out hardened grease before applying fresh grease

- Keep the grease exit port open for one hour so that excess grease (if any) in the bearing or housing will bleed out. Remove the bled out grease and re-assemble the exit port nut after one hour

Machine Restart Guideline

A general guideline to check the condition of lubricant (greases and oils) in machines after a prolonged stoppage to ensure maximum performance and avoid wear damage

- Do not start any bearing in full load and maximum speed condition immediately after the extended stoppage period. If possible, run the bearings under no-load conditions for one hour, before increasing the load and speed in steps

- Where ever-dynamic or static seals are provided in the equipment, check them for hardening and brittleness. Change the seals if they have become too hard or brittle

- Equipment that is prone for misalignment as per maintenance records should be checked for alignment before restarting them

- All grease guns and grease pumping equipment need to be recalibrated, before being put to use. Grease in containers to be checked for oil separation and stirred with a clean rod wherever necessary

- All oil storage drums should be checked for sedimentation and cleanliness. Thoroughly shake oil drums/ oil cans before taking oil for lubrication

- For rust removal of machine parts such as housing, bearings, gears, etc, Beruclean 3849 is recommended

The recommendations are based on our books of experience and available knowledge at the time of release. The general guidelines are to check the condition of lubricant (greases and oils) in machines due to unplanned stoppage that can be affected due to a combination of known and unknown factors including natural aging, the environmental impact of contamination by external impurities. For further reference and practices specific to the equipment, we suggest you follow the machine manually or contact the Service team. This information is intended as a guide and does not necessarily represent a marketing specification.

This content was originally published on the Bechem India website.