In the highly competitive Automotive industry, Quality Control is paramount to ensuring the reliability, safety, and performance of vehicles. Metrology, the science of measurement, plays a crucial role in achieving these high standards at every stage of automotive production and testing. Let’s explore explore how advanced metrology equipment, such as Laser Trackers and API’s new Dynamic 9D LADAR technology, are revolutionizing Quality Control in the automotive industry, with a focus on Body-in-White inline scanning using LADAR.

The Role of Metrology in Automotive Quality Control:

Automotive manufacturing processes are complex and require precise measurements to maintain tight tolerances and ensure the consistency of components. Metrology techniques are employed at various stages of production, from design and prototyping to assembly and inspection to gather the necessary data and report errors. With the introduction of advanced technologies like Laser Trackers (1983) and now LADAR (2022), metrology has become even more closely integrated in the automotive industry’s pursuit of excellence.

Laser Trackers and LADAR Technology:

Laser Trackers and LADAR (LAser Detection And Ranging) are two advanced metrology technologies that have gained prominence since their introduction to the market. Both systems offer high accuracy, speed, and flexibility, making them ideal for automotive applications.

Laser Trackers are known for their ability to measure large objects with high precision. They can be used to inspect and align car components, such as body panels, chassis, and suspension systems. LADAR, on the other hand, is an interferometry-based non-contact measurement system that provides fast and accurate data acquisition. It overcomes several limitations of conventional techniques, offering micron-level point clouds and eliminating issues related to surface reflectivity, slow data acquisition speeds, and restrictive incident angles.

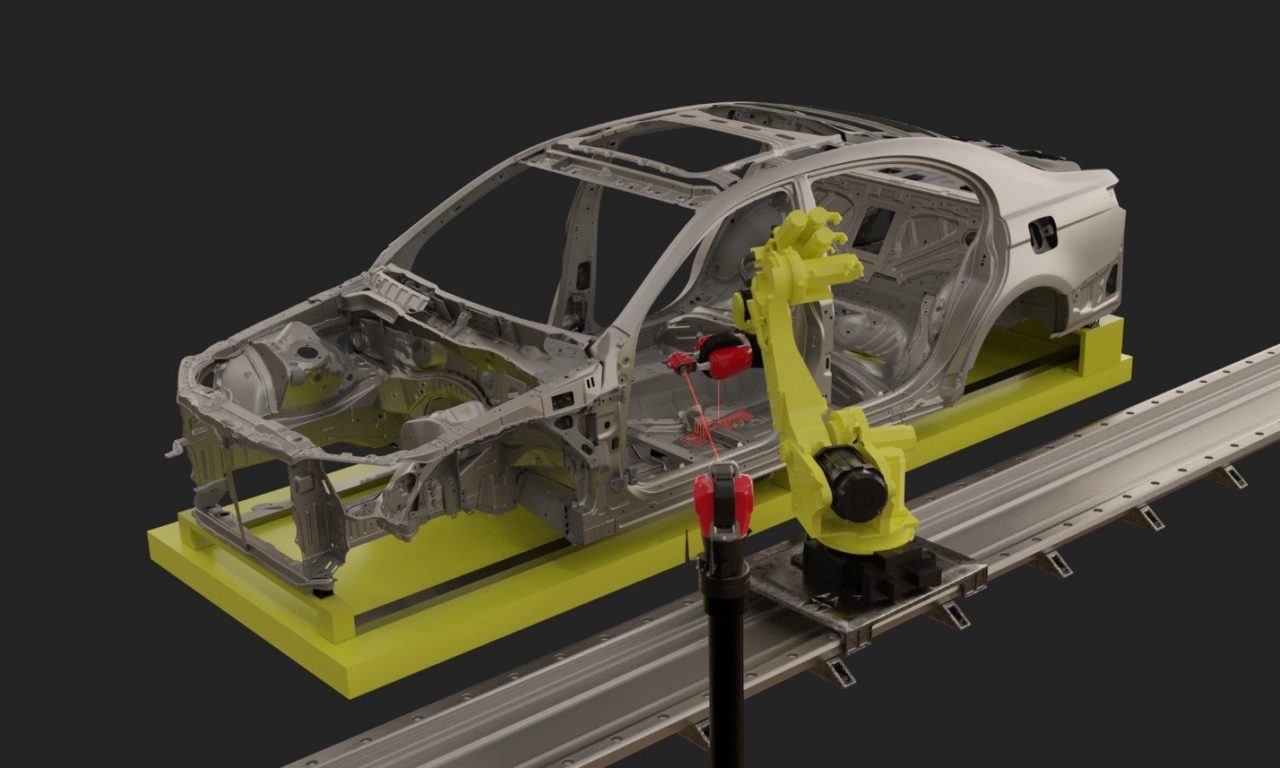

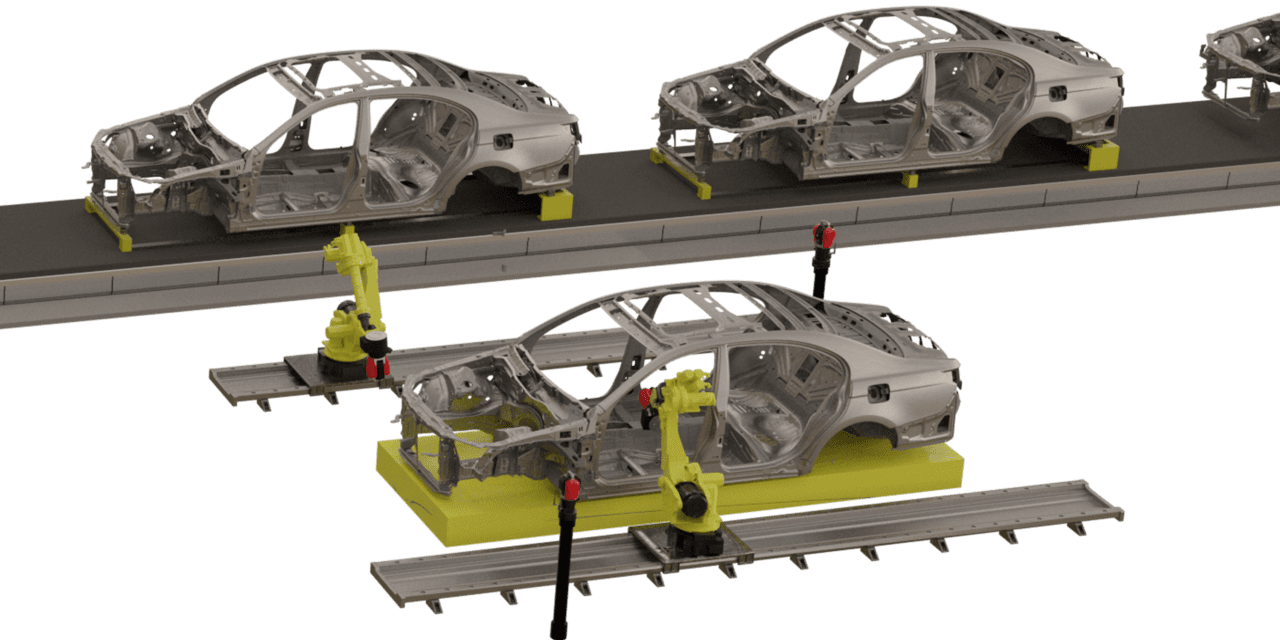

Body-in-White Inline Scanning with LADAR:

Body-in-White (BiW) refers to the stage in automotive manufacturing where the car’s metal frame is assembled before painting and the addition of other components. Ensuring the accuracy and consistency of BiW assembly is critical, as it directly affects the final product’s quality and performance.

LADAR technology is particularly well-suited for BiW inline scanning, thanks to its speed, accuracy, and non-contact nature. By rapidly capturing precise measurements in real-time, LADAR enables manufacturers to detect and correct deviations from design specifications during the assembly process, using a car wash and/or spur setup for various needs. This inline quality control reduces the need for time-consuming post-assembly inspections and minimizes the risk of costly rework or scrap.

LADAR Integration Benefits:

The integration of Laser Trackers and LADAR technology into automotive manufacturing processes offers several benefits:

Improved Quality Control: Advanced metrology technologies provide unparalleled accuracy, enabling manufacturers to achieve tight tolerances and improve the overall quality of their products.

Increased Efficiency: Fast data acquisition and real-time inline quality control reduce production times and minimize the need for time-consuming post-assembly inspections.

Enhanced Flexibility: Laser Trackers and LADAR can be used across various applications in the automotive industry, from inspecting large components to measuring intricate details with high precision.

Cost Savings: By detecting and addressing deviations early in the production process, manufacturers can reduce the risk of costly rework or scrap, ultimately saving time and resources.

Quality Control for the Automotive Industry.

The power of metrology, particularly advanced techniques using measurement equipment like Laser Trackers and LADAR, has a significant impact on enhancing quality control in the automotive industry. By enabling real-time inline scanning of body-in-white assemblies and providing unprecedented accuracy, these systems are revolutionizing automotive manufacturing processes. As the industry continues to evolve, embracing advanced metrology solutions and automated measurements will be vital to maintaining high standards of quality, safety, and performance in automotive production.

This content was first published on the API Metrology website.