API Metrology Automation Story

Automation is one of our namesakes. And while it is easy to focus on the innovative precision measurement equipment that founded our company and revolutionized industrial measurements and machine tool calibration, automation was in that first invention of the Laser Tracker as well. Dr. Lau’s inspiration for the first prototype was to find a way to make industrial robots more accurate in their automated processes by tracking and correcting their movements.

For more than 30 years, API has pioneered advancements in laser-based metrology equipment for industrial inspection and calibration, and a continual focus of that product development has been to deliver automation to the manufacturing floor.

API’s advanced 6DoF Laser Trackers, Scanners, and 9D LADAR provide customers with tools to complete complex production tasks with next-level speed and efficiency. Our customers can perform in-line inspection, automated measurement, and precision robot verification to increase production and decrease costs.

As a result of that focus, API has developed the most extensive portfolio of Automation packages in the industry, providing manufacturing-centric quality control and process control solutions. These solutions include RapidScan 3D optical scanner, mScan crossed blue-line laser scanner, Dynamic 9D LADAR (based upon high-speed frequency chirping interferometer technology), and Radian Laser Tracker Robot Calibration.

Our automated measurement solutions can inspect features as small as the edge of an aircraft engine fan blade or huge parts, such as wind turbine blades or complete car bodies, delivering real-time part measurement, feature inspection, point-cloud processing, and reverse engineering without the need for targets or stickers.

Making Robotic Processes More Accurate

With the dramatic uptake of robotic automation by manufacturing industries globally the need to define and enhance standard robot accuracy, and maintain robot accuracy over time, is critical in many of the most demanding robot applications. API developed Robot Metrology Solution (RMS), providing the necessary toolkit to verify robot performance, create error compensation models to deliver enhanced robot accuracy and provide robot programming and simulation tools using generated calibration data for corrected motion path execution.

API’s robot performance measurement procedure uses ISO 9283 guidelines to check for robot accuracy, repeatability, pose, distance, drift, overshoot, and path precision by exercising all robot joints. Using the API RADIAN 6DoF Laser Tracker and STS tracker target, random positions within the robot’s joint space are measured. API’s software models robot kinematics and defines the geometric relationships of robot joints by parameters (𝜃, 𝑑, 𝑎, 𝛼). API’s dynamic robot tracking solution uses automatic 6DoF Laser Tracker measurements to determine tracked robot position in real-time, revealing a robot’s true position and orientation and providing real-time robot path correction. The dynamic robot tracking solution is incorporated into API’s robotic SFIS.

Dynamic 9D LADAR

API’s Dynamic 9D LADAR incorporates a breakthrough technology set to revolutionize automated dimensional measurements, offering the world’s most advanced interferometry-based automated system incorporating high-speed Optical Frequency Chirping Interferometry (OFCI) technology.

9D LADAR replaces traditional, off-line, large volume coordinate measuring machines (CMM) and near-line and in-line inspection solutions using both laser-line and structured-light scanning sensors and delivers X,Y,Z, and I, J,K data for each generated cloud point along with the R,G,B, data allowing for scanned data to be imaged directly onto the captured camera image. The RGB data contained within the generated point cloud allows a full-color representation of the scanned part with associated fidelity, highlighting surface discrepancies and replicating the authentic color of the physical part.

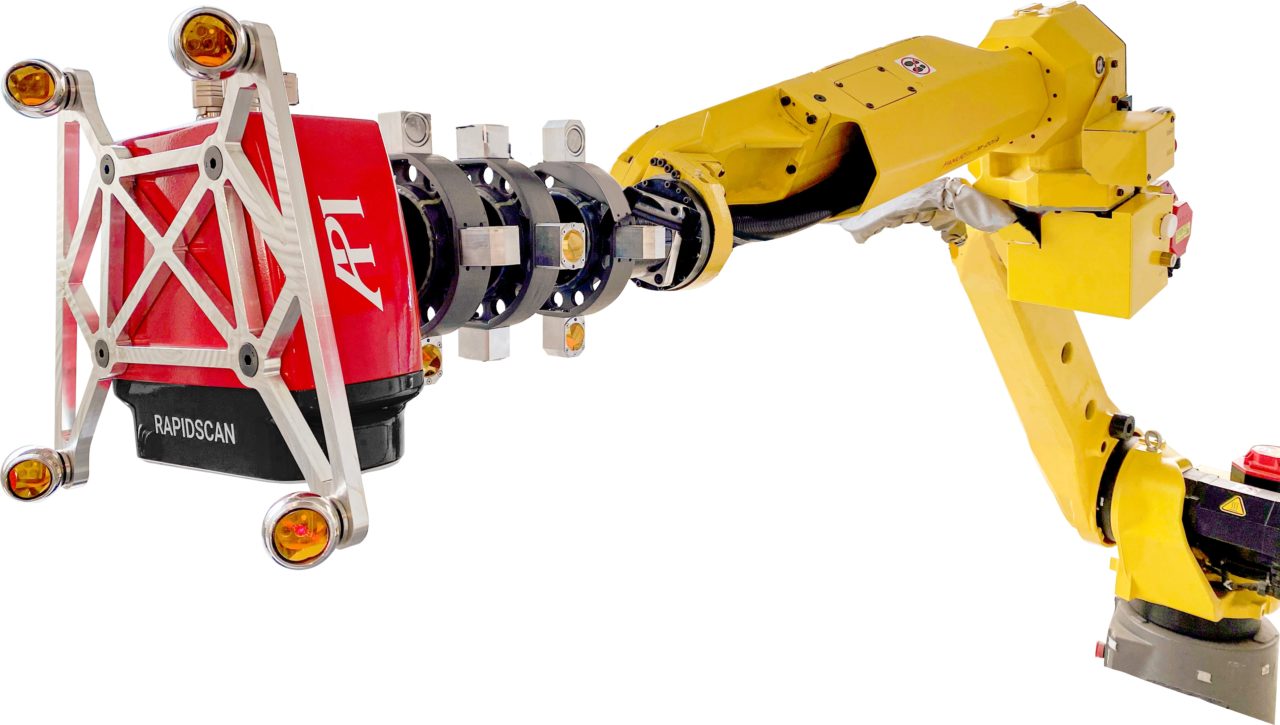

RapidScan RS3

API’s RapidScan hybrid optical scanner captures a 3D point cloud of the part within its large field of view. RapidScan’s high dynamic range stereo imaging is capable of measuring highly reflective and composite surfaces, completely eliminating the need for impractical part powder spraying. With sub-pixel edge detection, the (hybrid pattern) 3.2-megapixel optical projection generates a highly accurate dense point cloud.

Robot-mounted RapidScan can be integrated near-line or in a robotic cell to provide production part inspection.

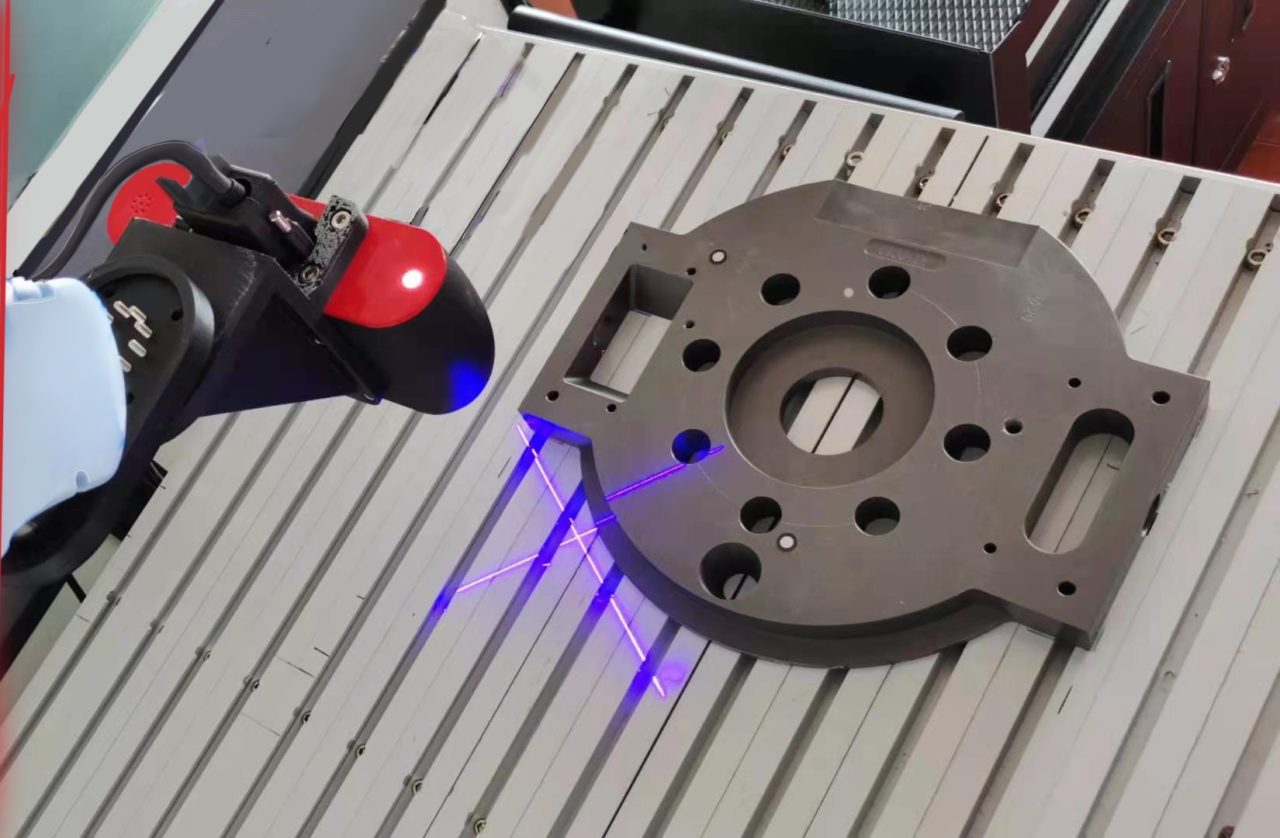

mScan

API’s mSCAN laser line scanner offers a fast, accurate, and productive solution to generate points clouds at the rate of 200,000 points/second. The dual crossed blue laser lines allow scanning in two directions simultaneously.

Robotic scanning of production parts using mSCAN offers a fast, efficient, cost-efficient measurement solution replacing traditional manual scanning operations for repetitive part inspection.

When integrated within an automated measuring cell, for shop-floor quality control, API turnkey solutions combine reliable hardware with robust software, allowing production process monitoring and trend and root cause analysis, delivering increased productivity and process improvements.

API’s automation packages deliver high-speed, precise real-time data collection at the accuracies needed to support manufacturing operations in the Aerospace, Automotive, Energy, and Military & Defense industries, and API is a partner to our customers, providing custom automated metrology solutions for real-world manufacturing environments.

To learn more about API’s Automation Solutions, fill out the form below to contact us and speak to a Real Metrologist today.

This content was first published on the API Metrology website.