Ansys: Optimizing Design Optimization Efforts

Simulation rarely occurs in isolation. An engineer may perform a stress simulation on the transmission mounts for a new car design, but that simulation likely takes place within a broader context; one that might also consider the stresses on the mounts of the engine, the rigidity of a car’s frame, and so on. Not only are there many different components of that design that one might subject to different simulations, but each component comprises materials — and reflects design decisions — that could be modified if the outcomes of these stress simulations are outside of acceptable specifications.

So many simulations. So many variables. How does one efficiently arrive at an optimized overall design?

Ansys optiSLang can help answer that question.

The Key to Robust Design Optimization

Ansys optiSLang is a process integration and design optimization (PIDO) solution that provides an organization with state-of-the-art robust design optimization (RDO) algorithms. It factors uncertainties and tolerance variations into account to automatically and efficiently identify the optimal configuration for a given design. Built into Ansys Workbench and Ansys Electronics Desktop (AEDT), optiSLang facilitates all aspects of RDO, including design exploration, optimization, robustness, and reliability analysis. It’s not limited to specific Ansys simulation tools, either. Organizations use optiSLang in automated workflows that can incorporate simulations using virtually any Ansys or non-Ansys product. These workflows parse and pass data from one step to the next and can run until design goals are optimally realized.

Using Ansys optiSLang, a manufacturing firm was able to increase design robustness early in the design process and achieve its six sigma reliability goals.

Many organizations have already created workflows that perform these kinds of simulations, but in many instances they involve significant manual effort. Engineers with expertise in Ansys Mechanical, for example, will run their simulations and then manually pass the output of those simulations to another engineer who specializes in simulations using Ansys Fluent. If the next engineer in the workflow uses a custom-built or third-party simulation tool, the salient data from Fluent or Mechanical may need to be extracted or transformed before it can be used in the next application. Each of these manual steps takes time, and each creates an opportunity for errors to creep in. While an organization approaching RDO in this way can realize clear efficiencies through the use of simulation software at each step, the overall workflow can only be described as discontinuous and inefficient.

Ansys optiSLang changes that dynamic. Its easy-to-use user interface (UI) simplifies the creation of workflows that automate multiphysics simulations, extractions, and transformations. It facilitates the inclusion of custom code and third-party applications, pre- and post-processing tools, and sophisticated processing and analytic loops. It facilitates the management of processing tasks across a high-performance computing (HPC) environment. It also interacts with Ansys Minerva, a knowledge management application that secures critical simulation data and provides simulation process and decision support to simulation teams across geographies and functional silos. For workflows that might be used by different groups within an organization, Minerva also enables a team to build and publish optiSLang-based web apps that can easily be used by others within the organization.

Ansys optiSLang facilitates the creation of a wide range of complex workflows connecting Ansys and third-party solutions.

Wrangling the Variables

The ability to link a wide range of parametric simulation tools provides unprecedented insight into the variables that can inform a complex design. But that insight can also be a bit overwhelming. If everything from an individual component’s material composition to its size, shape, and tensile strength can be manipulated, which are the most useful parameters to tune in pursuit of specified design goals?

Parameter identification is another area in which optiSLang shines. Ansys optiSLang relies on several design of experiments (DOE) algorithms, including the Meta-model of Optimal Prognosis (MOP) algorithm, that can analyze all these parameters and point an engineering team to the parameters that are most useful in a design refinement effort. With the insights provided by the DOE algorithms, an engineering team can quickly eliminate a wide range of simulations that it might have otherwise considered because those simulations would involve the manipulation of parameters that don’t make much difference. Instead, the team can focus on simulations that involve a much smaller number of parameters, which can considerably expedite design refinements and reduce design costs.

Using Ansys optiSlang to create a continuous workflow involving multiple simulation tools, one company reduced both total simulation time and total engineering time, resulting in a 56% reduction in stage completion time and an 84% reduction in costs. The 84% reduction in engineering time enabled the engineering department to accomplish far more over the course of a year.

Using optiSLang, a firm was able to reduce design iterations significantly by focusing in on those parameters that optiSLang identified as having the greatest impact on design goals. The optimized design led to increased margins and reduced manufacturing costs.

Refining the Design for the Real World

Just as optiSLang can help an engineering team determine which parameters can be optimally tuned to achieve the best design, it can also help determine whether the design itself is optimal in terms of desired robustness and reliability. It’s one thing to optimize a design to meet a given set of specifications; whether those specifications themselves are or are not optimal is another question entirely. What if the specifications achieve a level of strength or quality that is greater than actually necessary?

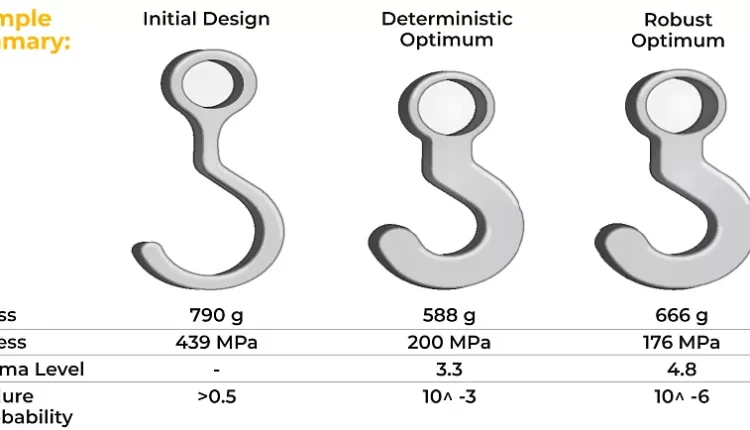

In any given engineering scenario, there may be uncertainties in required tolerances, loads, materials, and more. There may be a great deal of variation when it comes to the conditions in which a given device may operate or in which a structure will exist. Ansys optiSLang includes a series of robustness and reliability analyzers that take all these variations into consideration to help a team determine optimal tolerances, loads, materials, and more. If the specified quality level can only be achieved through the use of a particularly expensive material, but a different, perhaps more appropriate level of quality could be achieved through the use of a lower-cost material, then the organization might be able to meet the critical robustness and reliability goals while saving money by using a lower-cost material. Conversely, if the analysis of the variations suggests that the original design specifications were insufficiently robust, optiSLang can help the team determine where to make refinements that will result in a design more likely to meet overarching performance and reliability goals.

Indeed, such design tweaks might involve any number of parameters — size, weight, materials, and more — with the result being that the organization creates a product that will meet customer, regulatory, or other requirements in the most efficient manner possible.

This content was first published on the Ansys website.