by: Santosh Plakkat

The primary function of the CPX Linear blank preparation grinder is high material removal rate without compromising on dimensional accuracy and Surface finish of <0.2Ra.

The four axes grinder utilises the peel or the pinch-peel grinding method and is designed to adapt to a variety of blank grinding applications, including blank requirements within the cutting tool industry used in automotive, medical, woodworking, smart devices, aerospace and in the power-generation sectors of manufacturing.

Some of these applications include long series cutting tools, that are mostly used in machining deep sections, pockets, channels, and spot faces in castings and large components.

There are two categories within the long series endmills segment:

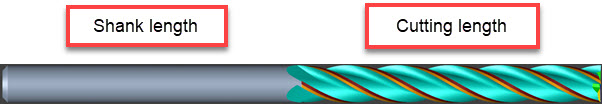

Long Reach Long Fluted Endmill

These are endmills that are ground with a long flute to its full OD cutting length. During machining, these tools are subjected to excessive deflection as the tool rigidity comes only from the core diameter, thus limiting the use only to finish milling applications and where a seamless machined surface is required.

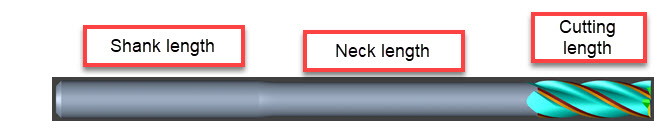

Long Reach Necked Endmill

These are endmills that are ground with partial OD cutting length and the reach section of the endmill is ground with a neck diameter. The neck diameter is cylindrically ground and is 0.5 – 1mm smaller than the cutting diameter. As the neck is solid without any flutes or features, the endmill is significantly rigid while machining.

Best Practice in Manufacturing Long Reach Necked Endmills

The process used in manufacturing these endmills vary depending on the cutting length, neck length, cutting diameter, cutting tool material and the material that needs to be machined. Below is one of the best practices in grinding long reach necked endmills.

Step 1: Grinding the Cutting Tool Features

- First. the cutting tool features are ground on a tool and cutter grinder

- A steady is engaged on the shank diameter to provide support while grinding the cutting tool features

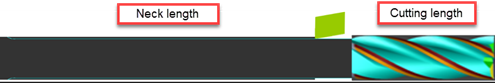

Step 2: Grinding the Neck Diameter

- The ground cutting tool is now loaded on to the CPX Linear blank grinder

- The neck diameter is peel ground by resting the shank on the V block support system

- The cutting length of the tool is skipped in the BlankX software while grinding the neck diameter

- Where required, the neck can also be ground using the pinch-peel grinding method

Key Benefits

- The shank diameter is generally a standard blank with a h6 tolerance, therefore supporting the shank while grinding the cutting tool features ensures that the steady support height is consistent.

- Auto loading and unloading is easier while gripping the shank diameter.

- Supporting the shank diameter in the CPX Linear ensures that the neck diameter is concentric to the cutting diameter – this is critical for the balancing of the tool.

- The CPX Linear software enables skipping of the cutting tool section, and only grinding the neck section.

This content was first published on the ANCA website.