Ace Micromatic: The Importance Of Lubrication For Machine Tools

A quality lubrication system is essential to ensure seamless machine operations. Lubricants may have many uses, but the primary function is to reduce friction between two mechanical parts. This, in turn, reduces wear, brings down operating temperature, deterioration of metal surfaces, and ensures smooth functioning and out of contaminants.

So taking machine tool lubrication seriously will definitely help maintain your machines along with increased longevity. Moreover, it is cost-effective and helps keep the company’s goals on track.

There are generally two types of lubrication systems – oil and grease for machine tools. Lubricants can be customized with other elements to suit the needs of an operation, based on the component being machined. Choosing the right mixture will not only elevate your machining process greatly but actually save your machine from catastrophic damages.

Discover the various aspects of lubrication that help a machine to perform efficiently and smoothly.

1. Oil lubricants

Oil lubricants maintain a free-flow consistency which is ideal to carry heat away from the source. This helps keep the base oil viscosity steady and reduces the risk of heat-induced oxidation and a gradual decrease of additives.

A lubricant’s composition starts with base oil which comes in three types – mineral, synthetic, and vegetable.

The benefit of oil lubrication is its volume which can be accurately controlled and can be changed without undoing machine hardware. Oil-lubricated machines make it easy to test for wear metals, contaminants, and fluid properties. This helps customize the oil better for operations.

Although oil lubricants are still the most preferred choice over grease lubrication and research says, that grease lubrication is more beneficial.

2. Grease lubricants

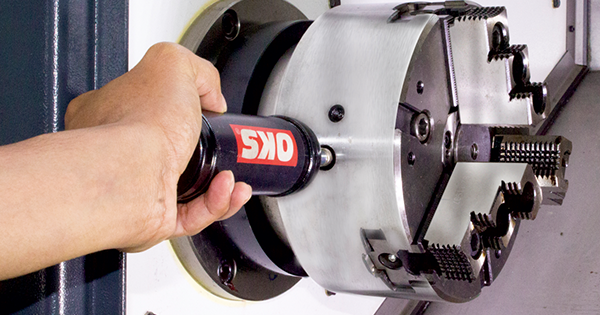

Grease lubrication offers great advantages over oil lubrication when it comes to maintaining CNC machine tools.

Here are the advantages of grease lubrication:

Cost-effective

Grease does not get washed away by coolant and maintains the right amount of oil film on your machine components. Grease uses a lesser amount of product as compared to oil. It is easy to use and needs a lesser level of maintenance.

Efficient

Chances of contamination are low since its storage comes in cartridges. It is not hazardous as compared to oil lubricants and it separates itself from the coolant to almost 100% which makes it easy to clean. It maintains a steady amount of grease and maintains consistency which allows stability during machining.

Eco-friendly

It has a low odor factor, making the work environment easy to be in. The cartridge concept keeps the product securely stored which keeps the floor and other areas of the shop floor safe to work in.

To know about the right lubrication system for your machining needs, kindly contact the Micromatic Machine Tools, service team.

This content was originally published on the Ace Micromatic website.