Cycle Time Reduction Secrets Revealed: Optimizing Non-Cut Time

Manufacturers are continually under pressure to improve the speed of their manufacturing operation. While it’s obvious that reducing cycle time is one of the easiest ways to speed up production, the benefits of more rapid production cycles are much deeper than what appears on the surface. Faster production ultimately impacts all facets of the business cycle.

Convert assets to cash more quickly: The sooner you can move material through your shop, turn it into the product, and get it out the door to your customer, the quicker you get paid. Cycle time reduction can help businesses improve cash flow.

Increase profitability and ROI: Cutting parts faster can reduce per-piece costs, which can lead to increased profits. This can also help to justify capital purchases by improving the ROI of a project.

Win more business: When you are quoting on contracts, cycle time directly impacts the cost per piece, which is a significant factor that determines whether you win the contract. Cycle time reduction can ultimately impact future sales.

More time for innovation: Cycle time reduction allows you to move parts through your machine faster, which, in turn, frees up time on the machine for innovation. To beat the competition, you need to keep moving forward by pioneering new techniques and products.

Improved customer satisfaction and better responsiveness: Long wait and delivery times do not make customers happy. Speed of delivery is key to customer satisfaction and can be greatly improved by reduced cycle time. In addition, moving product through your operation and freeing up machines make it possible to respond to new unexpected requirements.

Reduced WIP lessens the impact of unforeseen events: When it’s taking more time to finish cycles and WIP builds up, you are more at risk of being stuck with dead inventory during an unexpected event. For example, during the pandemic of 2020, many supply chains were abruptly stopped, leaving manufacturers scrambling. Improving cycle time can lower WIP and reduce risk exposure.

Five Cycle-Time Reduction Secret

A methodical approach should be taken when determining how best to reduce cycle time. Often, manufacturing engineers or CNC programmers will be tasked with finding cycle time savings and are under pressure to do it quickly. This can result in a scattered approach that does not always find the biggest bang for your buck. It can potentially add unnecessary risk.

Start with a Comprehensive Audit

It’s important to take time when assessing factors that could improve cycle time. The first place to start is auditing the process tool by tool to determine how much time is required with each step of the process. This can help you focus on areas with the most opportunity. Perform the audit by using system variables and macro statements to record the time for each tool and then compare them in a Pareto analysis. The Makino Pro6 control has a machining results screen that also can be used for this purpose. Once you’re armed with this data, you’ll be more effective at tackling the task of reducing cycle time.

Cut Time or Non-Cut Time?

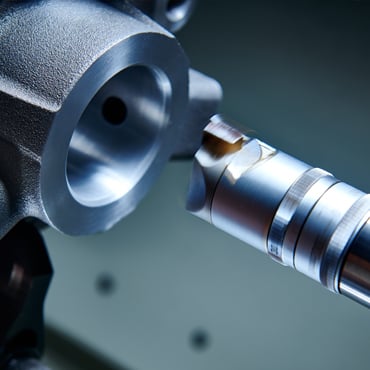

Next, it is important to categorize the time as cut or non-cut. Non-cut time is anything that does not involve making chips, such as positioning and turning coolant on/off. Making changes to the non-cut part of the cycle is a lower risk than changing the actual cutting process, which could result in part quality issues and broken tools. Avoid jumping straight to changing speeds and feeds when beginning your initial search for cycle time savings.

One of the ways to reduce non-cut time is by implementing special M-Codes to take advantage of parallel versus sequential movements. Makino has developed several M-Codes that execute simultaneous actions to save the time that normally would be required if each movement occurred one at a time. Below is one example of an M-Code developed by Makino and the actions that can be executed simultaneously:

M319

- Open the ATC shutter

- M19 spindle orient

- M9 coolant off

- Move to 2nd reference (tool change)

Optimize Non-Cut Program

Another way to reduce non-cut time is through program optimization. For example, reduce the R-plane (rapid plane) which is the position the spindle moves to above the part before beginning the cut. The closer you can get to the workpiece in a rapid move, the less time the machine is slowly feeding without cutting anything.

Eliminating inefficient steps, such as moving from the tool changer to the workpiece and back when not necessary, reduces cycle time. In addition, when machining multiple parts on a multi-sided fixture, start and end with features nearest to the tool changer. The tendency for many programmers is to code one face of the fixture and then just repeat the same sequence for the other side. Being smart about how you program multi-sided fixtures eliminates wasted movements that are not required.

Review Fanuc Parameters

There are also some potentially time-saving Fanuc parameter changes you can make. One of those is parameter 5001—which can be changed to enable a multi-axis move on the same line as the G43 tool length offset for the initial approach. Here is an example G-Code with this parameter enabled:

G00G90G54X60.Y-100.B270.G43H1Z5.S5000F1000.M303M08M26T05

In this G-Code you are positioning, calling your work offset, rotating the B-axis, tool length compensation movement, turning the spindle on, commanding the feed rate, and turning on the coolant. This is happening all at the same time, resulting in cycle time savings.

Another example of a time-saving parameter change is Fanuc parameter 5211. Changing this parameter to 200 increases the retract speed of a rigid tap cycle by doubling the speed on the way out. Of course, this suggestion, like all the others, should be tested to make sure these changes do not result in any detrimental effects. In this case, checking the threads of the tapped hole to confirm the quality is good with the faster retract is recommended.

Proprietary Product Features

Makino has also developed a number of built-in product features that can save a significant amount of time over the course of a production run. One of those is Inertia Active Control (IAC). This system analyzes the energy required for B-axis rotation based on the workpiece weight and inertia of the pallet. The machine software changes the acceleration settings of the B-axis rotation to enable reduced cycle times for smaller parts with lower weight and inertia. In a recent installation, a manufacturer of automotive steering housings reaped the benefits of this feature and was able to produce an additional 3,200 parts per year.

Makino’s application engineering staff has completed hundreds of turnkey projects over the last couple of decades and has been able to impart these and other cycle-time saving techniques to its customers. Our engineers are ready to answer questions, help you be more productive, and assist you in winning more business.