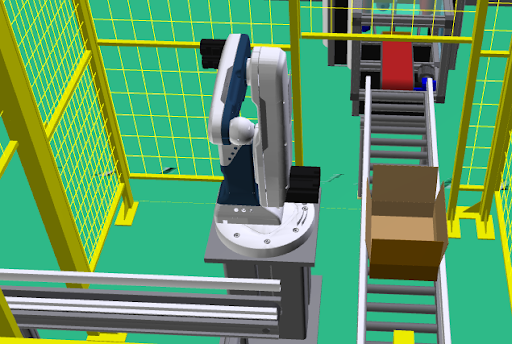

BRABO Carton filling and Robot palletizing system

Robotic Carton Filling System:

The robotic system is a high production system in comparison to manual operation. It is an extremely flexible and reliable system than any other conventional type of Carton filling system.

Robots are highly repeatable and accurate, which in turn helps to increase productivity. Brabo Robotics and Automation Limited promise reliable and cost effective solution, which helps for return on Investment.

The component can be a sachet, bottle, cup, small mini carton, packets, etc from FMCG, Food, Pharma industry, or any other industry where the requirement is to pack into the box. In the same line, there are different variants that need to segregate the items and put in a different carton box that may vary in sizes.

The vision-based solution helps to segregate the components/ to detect the components/ to detect the orientation of the component. Based on the feedback from the vision system, Barbo Robot picks the components with the help of Designed/standard Grippers and places them into the Carton Box. Sometimes the gripper is designed as per the requirement of the component or can be used standard gripper is available in the market. The robot places the components into the carton as per the predefined matrix.

A robotic carton filling system is a flexible solution. In the case in future some component dimensions, carton box dimensions, line speed or new additional component gets added or changed in the same line, Robotic solution is extremely flexible to adapt the change than any other mechanical conventional solution.

Food, Pharma FMCG sector, they have their manufacturing dynamic lines that have high-speed lines. Brabo Robot is the solution with multiple picking in a single cycle. Sometimes product volume (dimensions) is higher but weight is less, in that case, we can certainly say that “Yes, Brabo is the right choice”.

Robotic Palletizing System:

Robotic palletizing is an extremely flexible solution that gives high repeatability. A robotic palletizer is helpful to avoid manual fatigue and increase line efficiency. If you are storing the filled pallets in the Automatic Storage & Retrieval System (ASRS), then it is the system demand of ASRS for uniformity of stack onto the pallet. Robotic palletizing makes the stack very uniform as per the predefined matrix.

Single Robots can cater to multiple pallets with multiple variants. Two pallets can be catered by a single steady Robot. If you want to cater multiple Pallets then Robot can be movable onto the rail so that Robot can reach other pallets.

As per demand, multiple robots in series can be deployed to cater lines. Vision-Based palletizing solutions handle multiple variants at the infeed and the Robot makes different matrices onto the pallet at outfeed.

Brabo Robots have hands-on experience and expertise to provide the Best industry solution of Palletizing.

Mr. Vijayanand Bhalerao

Senior Member Business Development Team

BRABO Robotics and Automation Limited

This content was originally published on the Brabo website.