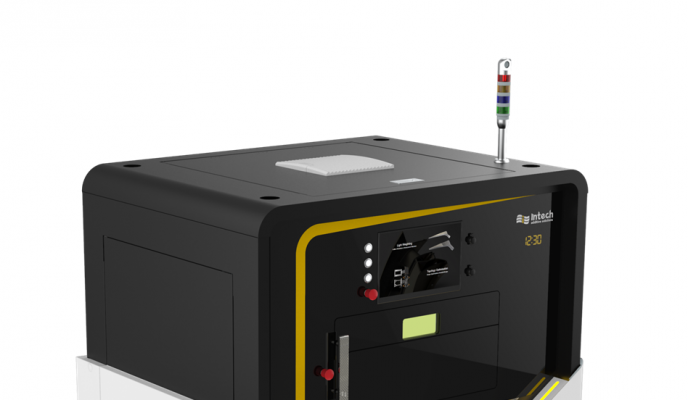

The iFusion SF1 Metal 3D Printer is based on Powder Bed Fusion (PBF) technology. Over 30,000 man-hours of Innovation and R & D have gone into its development.

The iFusion SF1 Metal 3D Printer produces parts with high structural integrity along with the required surface finish and mechanical properties. With the unique combination of a 500 Watt Laser and a larger build chamber in its class, it is a game-changer and meets the requirements of entry and mid-level component manufacturers.

Key features

- High build rate for cost-effective manufacturing

- The iFusion SF1 offers unparalleled power with a highest-in-class 500 Watt laser source, allowing one to print with higher layer thicknesses and build rates. A higher melting temperature enables the use of a wider range of alloys. A large build volume of 150 mm diameter and 180 mm height allows for nesting and stacking of more parts per build, making SF1 one of the best performing machines in its class, with the lowest per part cost.

- Precise & Reliable

- At the heart of the iFusion, SF1 Metal 3D Printer has recognized industry gold standard components like IPG lasers, ScanLab optics, and Beckhoff automation – which deliver unmatched performance, high precision, and a high degree of stability and reliability.

- Integrated Software

- Intech is the only OEM to supply its own software with its range of Metal 3D Printers, providing users with an end-to-end additive manufacturing solution. The SF1 offers ‘AMBuilder’ an integrated pre-build design software for Powder Bed Fusion (PBF) based additive manufacturing. MyBuilder caters to the needs of both beginners and advanced users. Its inbuilt algorithms incorporate Intech’s in-depth and extensive knowledge of the additive manufacturing process, enabling users to achieve the right build with the first print.

- Truly Customizable Parameters

- Intech’s ‘AMOptoMet’ parameter optimization software is available as an option with the SF1. It provides the optimum process parameters to obtain a better surface finish or desired mechanical properties. It reduces the time for the Design of Experiments (DOE) while developing new materials. You can gain complete control of what you wish to achieve while printing – like a faster build rate, desired surface finish, or optimum density. Users can customize existing alloys or develop new ones using AMOptoMet. It cuts the time required for the development of parameters from months to minutes.

- Value for money

- Intech SF1 Metal 3D Printer is designed, developed, and manufactured in India. The unique combination of a higher-powered IPG laser of 500 Watts, a larger build area, and a factory configurable laser focus diameter, enables users to efficiently manufacture multiple fine-featured dental components as well as larger cranial/hip implants or aerospace and automotive parts. It delivers unmatched performance and productivity, higher precision, better reliability with lower operation and maintenance costs. It is supported by readily available spares and quick local service – all resulting in a net reduced cost per part. This makes it the most competitive and versatile machine available in its class.

Applications

Aerospace Industry

Additive manufacturing enables the production of parts that are of lower weight, complex geometric designs while meeting the same strength requirements as parts manufactured by conventional means. In the Aerospace sector, additive manufacturing is often used for producing lightweight, strong aerospace parts like fuel nozzles and turbine blades.

Automotive Industry

The automotive industry combines additive manufacturing and simulation to create prototypes that can be tested for form, fit, and performance. This results in lower initial investment shorten the development phase of the product life cycle and enable a faster time-to-market for new models. Parts like intake manifold, fuel pumps, flow control valves, lamp parts, and mirror molds are developed using additive manufacturing.

Dental Industry

The dental industry employs additive manufacturing for producing customized crowns, bridge implants, and complete/partial dentures made to patient-specific requirements. It enables the generation of precise and smooth surfaces with minimal post-processing.

Medical & Healthcare Industry

The orthopedics and medical industry demand high-precision, perfectly fitting, patient-specific customized implants like Implants for joints (Titanium cups for hip and knee implants), Cranio-Maxillofacial implants, Implantable heart valves, and Rib cages.

Academic, Universities and R&D institutes

The iFusion SF1 is a perfect fit for Universities and R & D institutes carrying out instruction and research in rapid prototyping and additive manufacturing. SF1’s optional AMOptoMet opens up print parameter generation by allowing new parameters to be developed to print with customized alloys or develop new ones. A competitive price point and local availability of spares and support keep the operational and maintenance cost low.

This content was originally published on the Intech Additive Solutions website.