Ansys: 3D Printing Corporation Optimizes Additive Manufacturing Services With Multiphysics Simulation

As technological advancements continue to impact industries around the globe, additive manufacturing (AM) is becoming increasingly popular. Its global market is estimated to reach $76.16 billion by 2030, growing at a compound annual growth rate of 20.8% throughout the forecast period (2022-2030). 1

Environmental concerns play a role in its appeal, too, as companies are on the lookout for ways to boost efficiency while reducing material costs. To achieve this balance, many manufacturers are embracing digital transformation and adopting new technologies and methods. Simulation and AM support this shift by enabling manufacturers to design, test, and validate 3D parts before printing, which saves time, materials, and cost while helping to improve part quality.

Based in Japan, American-owned 3D Printing Corporation, K.K. (3DPC) is combining simulation and AM to help manufacturers develop alternative supply chains by providing a one-stop shop for strategic 3D printing services. Inspired to secure supply chains and prepare manufacturers for unexpected disruptions, 3DPC equips manufacturers with AM parts and services to optimize and digitalize their workflows. 3DPC works with several industries and markets, from toy companies to space stations.

With affordable access to Ansys’ multiphysics simulation tools through the Ansys Startup Program, 3DPC uses Ansys’ simulation to ensure the accuracy and durability of its 3D printed parts and materials. Through Ansys’ predictively accurate analyses, 3DPC verifies engineering dynamics, including structural integrity, thermal issues, fluid flow, and impact, while reducing material cost, optimizing its AM services, and increasing its customer base.

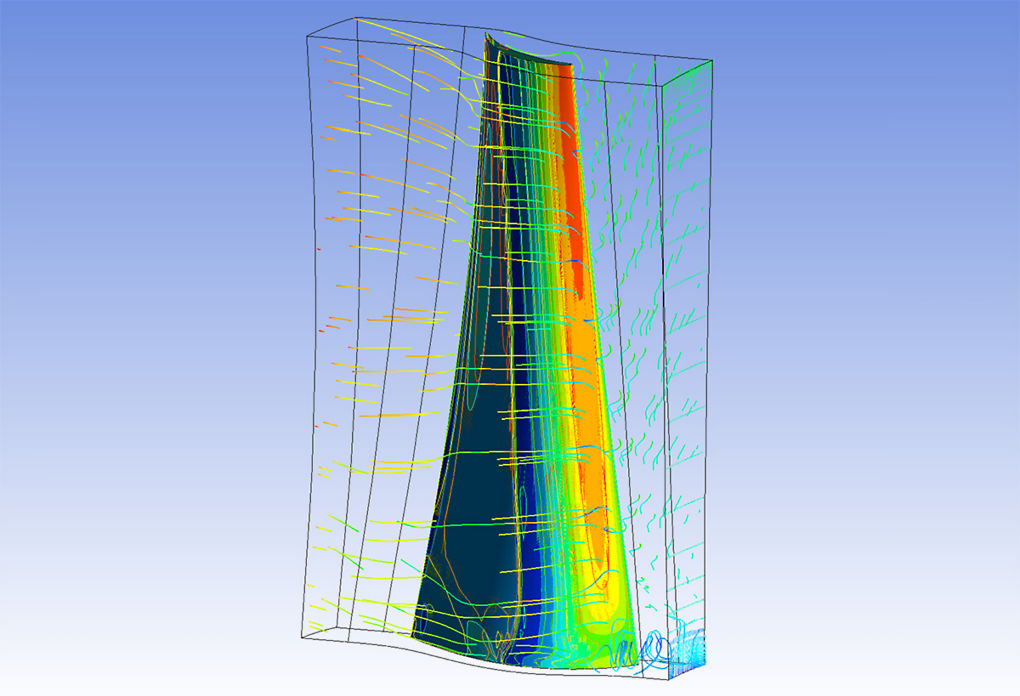

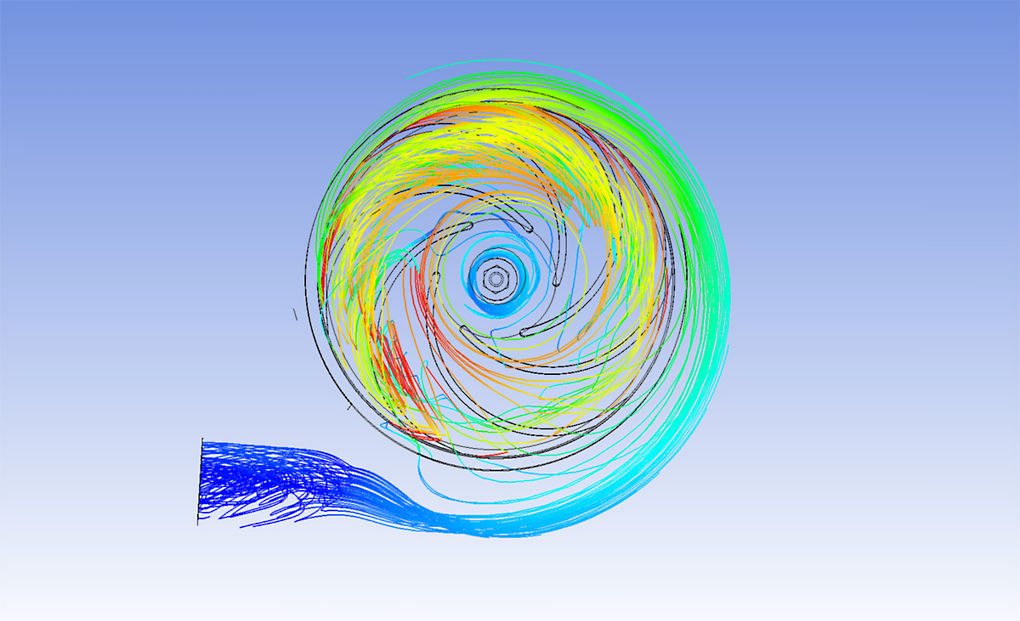

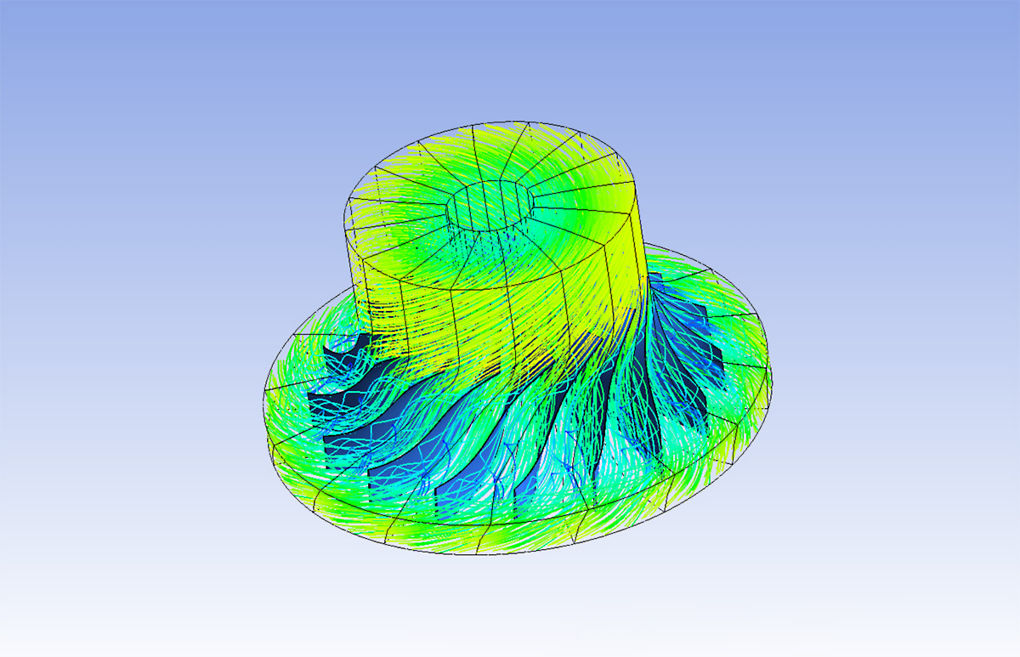

Designers at 3DPC use Ansys Fluent to analyze the fluid flow surrounding a centrifugal airfoil.

Challenge Accepted: Simulation Alleviates Additive Manufacturing Woes

3DPC works with a wide range of materials, including resins, metals, and composites. Predicting deformation is essential in AM to build parts successfully, keep costs down, and avoid mass printing errors. 3DPC uses Ansys’ multiphysics simulation tools to analyze and predict thermal deformation in advance and modify parameters.

It is equally important to balance strength and weight while constructing parts. Manufacturers seek strong parts, while their customers require them to be lightweight. To strike this balance, 3DPC uses the fused deposition modeling (FDM) method in conjunction with Ansys Mechanical and applied topology optimization. The team evaluates strength while considering the anisotropy of the FDM method and applies this to the topology-optimized model. In one example using this approach, 3DPC successfully reduced weight by 20% without reducing strength. By using Ansys’ simulation, the team was able to change settings and parameters such as boundary conditions until a desired ratio was achieved.

Ansys Fluent simulation of the fluid flow around a centrifugal pump

Ansys Fluent simulation of the fluid flow around a centrifugal pump impeller

For thermal analyses, 3DPC integrates Ansys Fluent to evaluate heat exchange efficiency and Ansys Additive Suite to predict thermal deformation using the powder bed fusion (PBF) method. Additionally, 3DPC uses Ansys LS-DYNA to assess shock absorption in elastomer materials and Ansys Discovery to analyze mesh data.

“Without the Ansys Startup Program, we wouldn’t have taken the steps to explore all the different module offerings from Ansys,” says 3DP Chief Executive Officer Alexander De Vore. “Some of them have had unexpected benefits to different parts of our process. So, that broad look into Ansys’ offerings helped us discover new ways to add value to our existing business.”

In addition to reducing part weight, 3DPC reduces material usage and increases part performance. For example, Ansys’ tools help 3DPC quantify the hardness and/or softness of AM parts such as lattice cushions. This insight not only improves the part, but also enables 3DPC to create stronger business proposals for clients with the ability to virtually illustrate part characteristics using simulation. With these advantages, combined with Ansys’ fast simulation turnaround, 3DPC has reduced time of sale, accelerated production, and secured new customers, resulting in a higher return on investment (ROI).

3DPC uses Ansys’ simulation tools during additive manufacturing to enhance part quality, such as the 3D printed cushioning in this helmet.

Satisfying Customers Through Simulation

3DPC offers four main services: design engineering, including a wide range of AM technologies such as PBF and fused filament fabrication (FFF); manufacturing via in-house equipment in 3DPC’s Japan factory; hardware integration consulting; and a digital platform where customers can place and track orders electronically.

Typically, 3DPC customers include organizations that need parts quickly, want high-performance components that leverage AM geometries, or are considering systemic adoption of AM but are not sure how to start.

To meet customer demands for faster part production, simulation helps 3DPC digitize analog components and tailor parts to customer specification in an accelerated time frame. In one instance, 3DPC helped a large organization with a global footprint reduce lead times by about 20%.

“We are able to get around a lot of trial and error by using some of the software models and design heuristics we have developed over the years,” says De Vore.

For clients hoping to enhance part performance using AM geometries, simulation helps 3DPC overcome common challenges such as engineering dynamics around weight, thermal dynamics, and electromagnetic properties. Most customers have already explored traditional geometries and seek new capabilities with AM. 3DPC meets these needs by providing integrated services from material selection to performance testing and material development.

As AM continues to grow in appeal and popularity, many businesses are intrigued by the technology but are unfamiliar with its processing. For these potential clients, 3DPC provides hardware consulting to assess specific needs and discuss possible solutions.

With critical insights from Ansys simulation, 3DPC can detect possible defects such as porosity in metal, which can happen during processing due to trapped air.

Manufacturing for Tomorrow

By integrating Ansys’ simulation throughout AM processing, 3DPC can apply important data-driven insights, which the team feels is pivotal.

“This type of digital modeling is critical because AM is a sequential process,” says De Vore.

Going forward, the startup will continue to enhance its business with Ansys’ simulation and plans to increase data insights by exploring the tools further and considering digital storage solutions.

“Some of the best outcomes have been winning new clients when we show them the model results,” says De Vore. “Decreasing our time to sale by integrating Ansys’ results and winning customers we otherwise would not has resulted in a very positive ROI for the business.”

This content was first published on the Ansys website.