Trumpf: A Quantum Computer For Sheet Metal Processing

DR. STOLLENWERK, YOU WORK AS A SCIENTIST AT THE JÜLICH RESEARCH CENTER. WHAT IS THE PROJECT ABOUT?

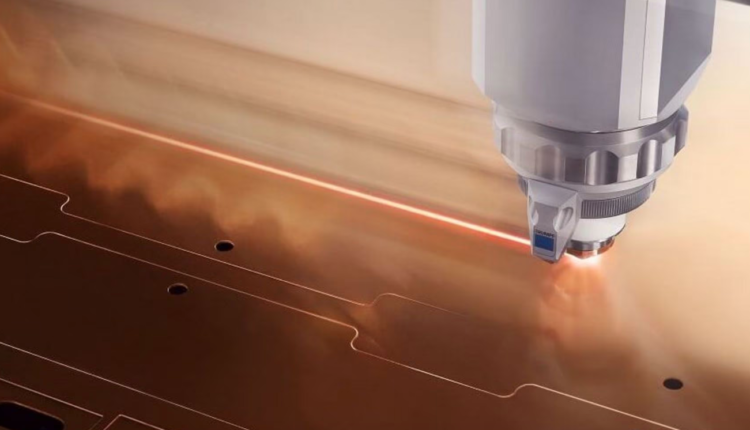

Stollenwerk: In the QUASIM project we are investigating the potential of quantum computers for metal processing. In doing so, we are concentrating on specific use cases. A test problem that we are investigating with TRUMPF is the removal of parts during laser cutting. These removal processes often do not have an ideal outcome, although they are already being optimized with the help of computer simulations. This is due to the fact that the thermal expansion of the sheet metal – the laser is very hot – can only be partially taken into account in current models. As a result, the cut parts sometimes get stuck on the sheet metal. The machines then have to be stopped to release the parts, resulting in unwanted downtime. Optimizing the cutting patterns with quantum computing and machine learning could help increase the efficiency and quality of the cuts.

HOW FAR ALONG ARE YOU WITH THIS APPLICATION?

Stollenwerk: Despite the enormous progress made in recent years, today’s quantum computers are still in the early stage of development. The current task is to break down the problems into sub-problems with similar characteristics to the actual tasks. These sub-problems are so simple that they can be solved on the currently available quantum computers with just a few qubits. With this method, we want to analyze the extent to which quantum computers can offer a real quantum advantage in practice for this specific task. Another question being addressed is what properties such a quantum computer must have and how high the associated development effort is. An important goal at the end of the project is to obtain an estimate of which quantum computing resources would be necessary to achieve a quantum advantage in practice. So far we have developed the initial approaches for using quantum computers to accelerate machine learning methods, and how these can help simulate temperature propagation in the sheet metal parts.

WHAT IS YOUR ROLE IN THE PROJECT?

Stollenwerk: The QUASIM project is a collaboration between the German Research Center for Artificial Intelligence (DFKI), which is coordinating the project, as well as the Fraunhofer Institute for Production Technology (IPT), TRUMPF and the ModuleWorks software company in Aachen. Ford and MTU are also involved as associated partners. My role is to coordinate the work at the Jülich Research Center. My colleagues Dr. Alessandro Ciani and Sven Danz carry out the actual research and investigate quantum algorithms that are potentially suitable for manufacturing.

WHICH QUANTUM COMPUTERS ARE YOU USING IN THE PROJECT?

Stollenwerk: Right now we are still simulating quantum computers on traditional computers. This has the advantage that we can concentrate fully on the development of the quantum algorithms and can pay less attention to the peculiarities of current quantum systems, which are typically still somewhat error-prone. Nevertheless, we are already taking into account the properties of real quantum hardware, such as those being developed in the Qsolid project. Some examples of these properties are error rates in special quantum operations and the limited connectivity of the qubits.

This content was originally published on the Trumpf website.