3D Scantech: What 3D Scanning Can Do for Reverse Engineering

What Is Reverse Engineering?

Reverse engineering, also called backward engineering, is the process of analyzing a physical object to understand how it works and create a digital model of it.

This technique can be used to create new versions of products or to improve obsolete ones. It is a valuable tool for engineers and designers to work with existing products that lack technical documentation or CAD models.

The techniques for reverse engineering have evolved from manual measurements to 3D scanning, which provides a variety of possibilities.

3D Scanning in Reverse Engineering

High-tech 3D scanning for reverse engineering is a technology that captures the 3D data of objects by using lasers or structured lights, from which you can obtain information about their shapes and dimensions.

From 3D scanning, users can obtain point clouds that represent the surfaces of objects and can be converted into mesh models.

Categories of Measuring Methods

There are different types of measurements available for backward engineering applications, depending on the size, complexity, accuracy requirement, and material properties of the object to be scanned. Some common categories are:

Contact Probes: Engineers use probes to measure the object’s surface and obtain its coordinates. Contact scanners are accurate but slow and may damage delicate or soft objects.

Non-contact 3D Laser Scanners: Non-contact handheld 3D laser scanners for reverse engineering mainly fall into two categories, 3D laser scanners, and structured-light 3D scanners. By emitting laser beams onto the objects, professional 3D laser scanners can obtain the coordinates of points on the surfaces and objects

Non-contact Structured-light 3D Scanners: Portable 3D scanners project patterns onto objects and use cameras to record how they deform on their surfaces.

Therefore, these 3D scanners can obtain the geometrical details and even colors and textures of products. No-contact 3D scanners are versatile, accurate, and fast to capture 3D data.

They can conduct full-field 3D scanning without causing any damage to objects. Some of these 3D scanners may have difficulties with reflective, dark, or transparent surfaces.

Photogrammetry: This technique uses multiple images taken from different angles to reconstruct the shape of an object. Photogrammetry is easy to use but requires high-quality images and may not capture fine details.

Scantech’s Industrial 3D Scanners for Reverse Engineering

The KSCAN-Magic series 3D laser scanner is the first that combines infrared and blue lasers into one single instrument.

It offers five standard working modes:

♦ Large-area scanning (global initiative infrared laser)

♦ Fast scanning (blue laser crosses)

♦ Fine scanning (blue parallel laser)

♦ Deep-hole scanning (single blue laser)

♦ Built-in photogrammetry system.

With two sets of high-definition industrial cameras, it can conduct 3D scanning meticulously. It is suitable for backward engineering in industries such as manufacturing, energy, automotive, and rail transportation.

Workflows of 3D Scanning to CAD Modelling

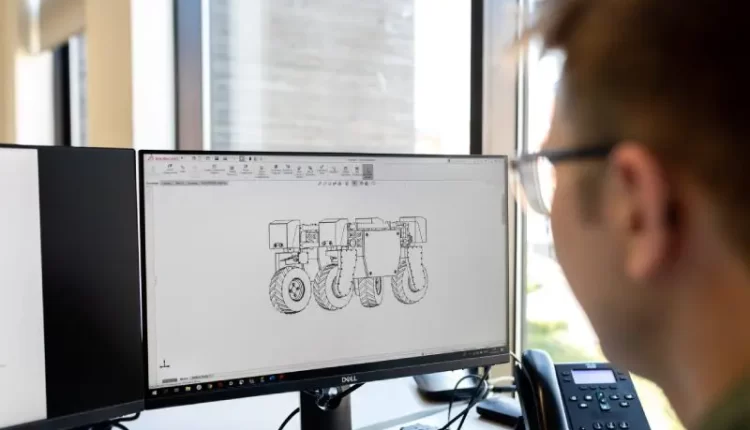

Once an object is scanned using a 3D scanner, it can be reverse-engineered using software tools that allow editing, modifying, analyzing, or recreating its design.

Some common steps involved in reverse engineering using 3D scanning are:

3D Scanning: 3D scan the part with high-precision and professional 3D laser scanners to capture point clouds.

Point Cloud Processing: Clean up noise, outliers, or unwanted points from the point cloud data.

Mesh Generation and Optimization: Convert the point cloud into a mesh model and refine the mesh so that the data can be more manageable in CAD.

Surface Extraction: Import the mesh to CAD software and extract important surfaces. This step involves generating smooth surfaces that fit to detected regions of the mesh model. Designers can create sketch planes quickly and accurately using the scan model as a reference.

Solid Modeling and Re-design: Converting the surface into a solid model by defining features, parameters, and more. The solid model can be used and modified for further design.

Benefits of Using 3D Scanners

Measure Complex Parts

3D scanning can be used to capture complex shapes that are impossible or difficult to measure for traditional methods.

Thanks to their laser scanning and non-contact measurement, it is much easier for handheld 3D scanners to measure narrow spaces, hard-to-reach areas, or parts with intricate details such as gears and turbines.

As a result, designers are able to create realistic models that reflect real-world features and engineers can design new products based on existing parts efficiently.

Enhance Creativity and Innovation

The use of 3D scanning for reverse engineering can enhance creativity and innovation. By using a 3D scanner, designers can explore different ideas and possibilities based on existing objects.

For example, a 3D scanner can scan an existing car model and then modify its curves to improve aerodynamics digitally.

Alternatively, a 3D scanner can scan multiple objects and combine them into a new design. This can allow designers to create unique products that meet specific needs.

Save Time and Money

Using 3D scanning for reverse engineering can save time and money when compared to traditional methods.

For example, instead of measuring an object manually with calipers or coordinate measuring machines (CMMs), which can be slow and troublesome, a 3D scanner can capture millions of points on the surface of an object in seconds with high accuracy. This can reduce errors and rework, as well as speed up the design process.

This content was first published on the 3D Scantech website.