Mastercam: How Material is Chosen for Different CNC Machining Applications

CNC machining refers to the process of using a computer numerical controlled machine to systematically manufacture pre-designed parts by cutting stock material in a specific way. These days, that stock material can be any one of a number of pure metals, metal alloys, or even plastics. Determining which of the many material options to use can be tricky. In this blog, we will delve into some of the features of the most commonly used materials in machining.

Starting the process

In order to choose the best material for a part, it is crucial to understand the part inside and out. This consists of considering its size and how many parts can be machined out of one unit of any one material. This gives an indication of cost. Then, the part’s intended use is considered as well as what sort of mechanical and thermal stress it will handle. Parts that have to hold up against high heat or under heavy loads will naturally require sturdier material.

The part’s toolpathing is the last factor in the decision. Are there any intensive cutting processes that will allow dangerous heat to build up, potentially warping less durable material? Is there a chance that certain feeds and speeds could cause the material to shatter or fracture? The right CAM software will reduce the chances of material damage, allowing machinists to use a wider range of materials and often saving money. Because of this, it is critical to have the best software installed and to have your machining well-organized.

Once all of these factors have been tallied and analyzed, a decision can be made as to which material is best. In the end, the best solution will be one that prioritizes part performance, machinability, and cost-effectiveness.

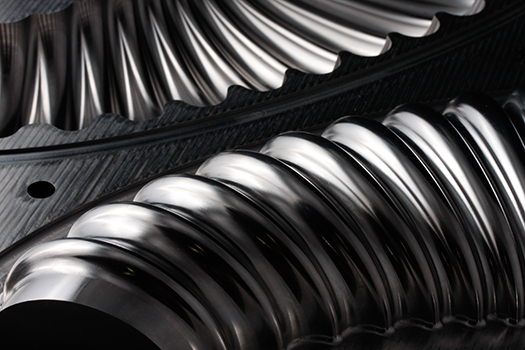

Analyzing the most commonly used materials in CNC machining applications

Aluminum

Aluminum and aluminum alloys are some of the most common materials for prototyping and aerospace parts because of aluminum’s superior strength-to-weight ratio. Essentially, this means that aluminum is relatively light for its strength. This is particularly helpful for automotive and aerospace parts, where the finished product needs to be as safe as possible while also having the least possible amount of mass. Unfortunately, aluminum is more expensive that steel and more difficult to weld.

Brass

Brass is an alloy of copper and zinc. It is often paired with lead, which makes it the most easily machined of all the copper alloys. Like copper, brass is thermally and electrically conductive. It is also mechanically stronger, lower-friction, and more resistant to wear and corrosion than pure copper. Because of this, it excels in areas like the marine industry, where corrosion-resistance is important.

Bronze

Bronze is another copper alloy, containing tin and lead. Again, the inclusion of lead makes machining easier. Bronze is also exceptionally low-friction, making it ideal for parts in high-friction environments. However, bronze is fairly expensive and somewhat less sturdy than other structural metals and alloys.

Cast Iron

Cast iron is recognized for its relatively high machinability, making it a very straightforward material to have in a shop. Its hardness varies from composition to composition, but most cast irons are fairly strong. While it is also comparatively cost-effective, cast iron lacks steel’s ductility and is very brittle.

Stainless Steel

Steel, specifically stainless steel, is one of the most common materials found in machining shops. There are as many compositions and grades of stainless steel as there are applications. Depending on its chemical makeup and heat treatment, stainless steel can vary greatly in its heat resistance, machinability, corrosion-resistance, and strength, but all excel in these categories compared to other metals. Its downside is that is expensive and sometimes difficult to machine.

Titanium

Titanium is considered an “advanced” material that not every shop uses. It is lightweight, corrosion-resistant, and strong even at high temperatures. Titanium is also biocompatible, making it perfect for medical applications. Naturally, titanium is very costly.

Plastics

Modern CNC machining has evolved to include plastics as well. There are several that are often used: polypropylene, nylon, acrylic, polycarbonate, PVC, etc. While most plastics cannot offer the same strength and heat resistance that metals can, they are invaluable for prototyping and design testing. Plastics are also much less costly than metals and metal alloys.

Learn more

If you find yourself struggling to find the perfect material to survive machining, perform well as a finished part, and keep your shop profitable, it may be time to look critically at your machining approach. By minimizing excess heat, chatter, and unoptimized cutting, you may be able to use less expensive or more impressive materials. Reach out to your local Mastercam Reseller today to find out more.

This content was first published on the Mastercam website.