Until the turn of the millennium, the innovation potential of machining was considered to be largely exhausted. Notable improvements usually resulted primarily from the use of new tools and materials, faster and “more intelligent” parameter optimizations or their targeted adjustment to individual problems and process variables with the aid of modern control generations. Otherwise, productive progress tended to take place in the machine tool environment – until the breakthrough of ultrasonic-assisted machining about two decades ago.

The process revolution was triggered by ever-increasing requirements as a result of new workpiece materials from the field of so-called “advanced materials”. In particular, earlier developments that had previously been considered exotic due to their low general relevance gained in importance. One of these developments is ultrasonic-assisted materials processing, which dates back to the 1950s, but did not achieve an industrial breakthrough until the end of the last century. Since 2001, ultrasonic-assisted machining has been part of the portfolio of DMG MORI, where the process was declared part of the program under the ULTRASONIC brand.

Convincing arguments

The hybrid core of ultrasonic-assisted machining involves simultaneous superimposition of tool rotation with an axial oscillating movement in the high-frequency range as an additional effective component for material removal. Experts refer here to the piezoelectric effect, which is used to virtually “knock out” minute particles from the surface of the workpiece. This sounds crude, but the result is material removal of the very finest quality for the toughest and hitherto inadequately unsolved tasks in metal-cutting production technology.

The secret behind the success of the ULTRASONIC process is in particular the reduction of the prevailing process forces by up to 50 percent compared to conventional machining processes. This allows feeds and infeeds to be increased, surface finishes to be improved or tool wear to be minimized – depending on the requirements.

On the one hand, this reduced the immediate costs, but on the other hand it also ensured the process quality that is elementary for industrial applications. In addition, there was a drastic reduction in temperature development at the point of action between the tool and the workpiece. Materials that had previously been considered delicate, such as ceramics, silicon or glass, could suddenly be machined efficiently. Manufacturers of wear-free ceramic components in the textile and pump industries benefited from this, as did processors of SiC, quartz glass and Zerodur in the optics/semiconductor industry or highly stressable material combinations in aerospace and automotive engineering.

Soon, multi-unit bridges, bars and implants from the dental sector could also be made to fit with µm precision as a ceramic 1:1 image using the 3D data of the original tooth. DMG MORI has also succeeded in opening up the ULTRASONIC process for composites, carbide or corundum, for example, all of which are resistant to wear and corrosion, pressure, shape and temperature.

However, the mere shift in the direction of advanced materials was not the only reason for the subsequent triumph. It required at least one other ingredient, namely maximum precision. This is best illustrated by the extreme surface qualities of up to less than Ra 0.1 μm. In concrete terms, this means that the differences in height and depth over the entire surface of a component are within a range of 0.1 µm. Machining marks of this quality are no longer visible to the human eye.

In order to nevertheless be able to convey extraordinary precision, a short intermediate calculation helps. 1 µm or one micrometer is the millionth part of a meter. If you divide this result by 10, the bottom line is the surface quality of a component after ultrasonic machining.

In addition to the excellent properties in terms of surface quality and dimensional accuracy, this precision in combination with the reduced process forces has also created room for new applications. One example is the use of ULTRASONIC in the semiconductor industry. Users from this technology sector have already appreciated DMG MORI’s “ultrasonic machines” in the production of precision components made of technical ceramics, quartz glass or even Zerodur for more than 15 years. These workpieces, in turn, are key components that are indispensable in lithography systems for manufacturing increasingly powerful microchips. The new ULTRASONIC MicroDrill micro drilling spindle was also developed for this industry. Depending on the material and process parameters, it can be used to reliably drill 10,000 holes down to a diameter of just 0.1 mm in glass and ceramic components.

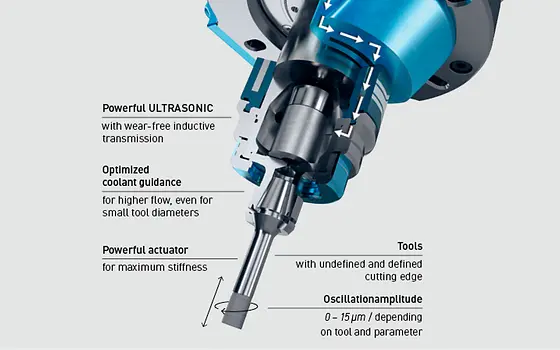

The technological basis for this fine form of ULTRASONIC processing “serves” the reverse piezoelectric effect, under which special piezo elements expand or contract when a voltage is applied, which ultimately gives the so-called ULTRASONIC actuator its power. Specifically, this involves a suitably equipped and upgraded HSK tool holder, which is thus able to guarantee a high amplitude power of up to 15 µm. Another special feature here is that the machine tool can be used both as an ultrasonic machine and as a standard machine due to the exclusive generation of mechanical vibrations in the tool holder. In addition, the required electrical energy is transmitted by a wear-free inductive system, which enables full compatibility with automatic tool changers.

The link between spindle and tool is available in the hollow shank taper versions HSK-E32, HSK-E40, HSK-A63, HSK-A100, depending on the machine size. The hollow shank taper is a high-precision further development of the steep taper and offers the perfect prerequisite for bringing the unique advantages of the process to the effective point between the ULTRASONIC tool and the workpiece.

The new compatibility was soon reflected in the increased diversity of the DMG MORI portfolio. In addition to a series of flawless ULTRASONIC offerings, most 5-axis milling machines in the DMG MORI portfolio can now be upgraded in terms of production technology with the impressive ULTRASONIC capabilities. The machinable workpiece spectrum ranges from small workpieces to large parts machining.

This content was first published on the DMG Mori website.