Walter doubles Tiger·tec® Gold range for turning applications

Tool life increase: Around 50%

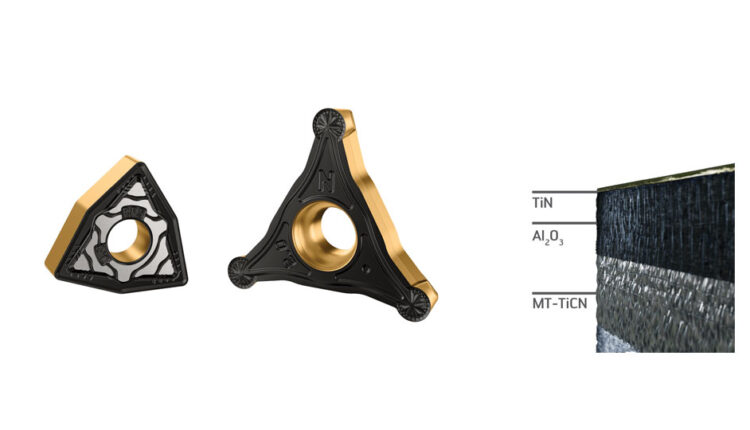

With the WPP10G grade for continuous cuts and occasionally interrupted cuts, the WPP20G universal grade and the tough WPP30G grade for interrupted cuts and unfavourable machining conditions, Walter offers its customers three Tiger·tec® Gold grades specially designed for turning operations. After the extremely successful market launch at the end of 2021, the manufacturer is now doubling its range. The positive CCMT and DCGT inserts, as well as negative, single-sided CNMM and SNMM inserts, and WL25 copy turning inserts are now being added to the previously launched indexable inserts with double-sided negative basic shape (CNMG, DNMG, etc.).

They are expanding the Walter Tiger·tec® Gold portfolio with three cutting tool materials, now taking the total to 21 geometries and more than 1100 items – including special geometries with improved chip breaking (MP6) and for roughing large forged parts (HU7).

Like the existing inserts, steel is the primary application of the newly added turning grades (cast iron is the secondary application). In 130 customer tests, they increased tool life by an average of around 50%. The reason for this is a special layered structure. A patent-pending, highly textured, multi-layered MT-TiCN layer increases toughness and reduces flank face wear, resulting in lower production costs. The highly textured Al2O3 layer also minimises crater wear; the final gold-coloured top layer improves wear detection.

On top of this, Walter provides a multi-stage post-treatment. This produces an unusually smooth rake face, therefore reducing friction and also increasing toughness. This ultimately ensures high process reliability in automated processes. With this expansion of the product range, users can now benefit from maximum flexibility and minimal component costs when turning too, thanks to Tiger·tec® Gold.